The Yutong Xiaoyu 2.0 has been awarded the design prize 2021 Red Dot Award. Developed by the Chinese group, the 5.5-meter shuttle bus stands out for being the world’s first autonomous bus recognized by world-class industrial design award, as well as the only bus brand in China winning Red Dot Award.

Xiaoyu 2.0 is an autonomous public transport solution that inspires trust in passengers. In 2020, Yutong sales volume of large and medium-sized buses reached 41,756 units, among them 16,461 units are new energy buses. The bus producer reached sizable sales volume in over 30 countries and regions such as France, UK, Australia, Russia, Saudi Arabia, Kazakhstan, Mexico, Norway with a market share of over 35% in China and over 13% in the world.

In late November 2020 the producer secured the widest order so far for battery electric buses in the world: 741 e-buses are set to be running in Qatar by 2022 in view of the FIFA World Cup Qatar. They will be deployed by Mowasalat, which ordered in total 1,002 vehicles from Yutong.

The design of the bus has been inspired by spacecraft, precisely by space capsule. The symmetrical design from the front and back has the goal of promoting strong visual identification. Engineering and aesthetic factors are smartly reconciled by excessive size porthole and the mapping of laser radar and lens.

Chinese e-bus wins 2021 Red Dot Award

Sustainable mobility: the excellence Italian National Pole was born

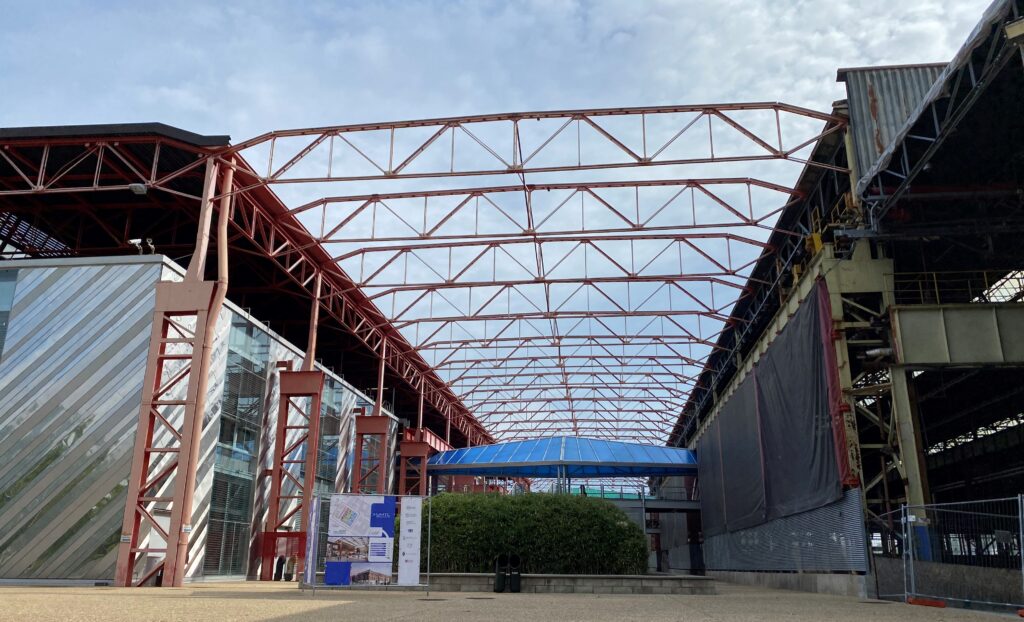

Last July 16th was presented the project of the National Pole of Sustainable Mobility and Manufacturing, also called SMTC, Sustainable Mobility Technology Center, which will be established in TNE spaces of Corso Settembrini 178 in Turin.

We, too, from Electric Motor Engineering were present, to be able to tell you at best this new Italian pride that exceeds a further border and involves more players of different nature: Turin Polytechnics, University, CIM 4.0, API, Turin Trade Chamber, Industrial Union, Piedmont Region and city of Turin.

The target is accompanying enterprises, especially small and medium-size ones, towards a course of innovation and training, giving them the possibility of using sophisticated tools, at disposal just with investments worth million Euros.

The keyword is technological transfer, a possibility that can be implemented through the creation of a sound network and the contamination between technologies and competences, also due to the establishment of territorial companies, but not only, at the Pole’s.

The keyword is technological transfer, a possibility that can be implemented through the creation of a sound network and the contamination between technologies and competences, also due to the establishment of territorial companies, but not only, at the Pole’s.

Within 2023 this new excellence should become concrete, with Turin at the core of the capability of doing system, to full benefit of research, innovation and technological transfer to offer training services and activities.

All this is completed by a project of sustainable reorganization of an area still unused, feather in the cap of the automotive manufacturing, where the smartest companies will be attracted.

During the launch event, it was possible to visit the pilot lines that will be the technological core of the Pole: the Additive Manufacturing Pilot Line, the Laser Powder Bed fusion and Direct Energy Deposition.

Italian excellences: the president of Euro Group appointed Knight of Merit of the Republic

Sergio Iori, the president of Euro Group Laminations has been recently appointed Knight of Merit of the Republic.

President of EuroGroup Laminations

His professional commitment has given an outstanding level contribution to the field of stators and rotors for electric motors and generators.

Not fortuitously, Euro Group Laminations currently represents one of the most dynamic and smartest realities in the world panorama of specific hi-tech.

These are good news for Italy and the Made in Italy pride, for a company with almost 2,000 workers, 7 manufacturing plants in Italy and 5 abroad, with a consolidated turnover of over 400 million Euros, which exports worldwide and highlights our Country’s excellence everywhere.

Virtual Technical Inspection, excellence of Turin Polytechnics

The student team of Turin Polytechnics H2politO stood out in the international competition for low energy-consumption vehicles, Shell Eco-marathon 2021, ranking 7th in the world list with JUNO prototype and 25th with IDRAkronos. However, it is worth highlighting the particular places in the 1st Global ranking Virtual Technical Inspection for the Prototypes category and the Urban Concept category, the 3rd Global ranking Pitch the Future “Decarbonising the home” and the 2nd EMEA ranking Overall Europa & Africa ranking Simulate to innovate Off-track Award.

The Virtual Technical Inspection race required presenting, in a 7-minute video, all the aspects of the vehicle that make it compliant with the regulation, also from the safety point of view, for the participation in the Shell Eco-marathon.

«Despite difficulties – stated the professor Massimiliana Carello, Faculty Advisor of H2politO Team- the Team has worked with passion at this new competition typology, achieving an important result. This goal is the fruit of the team’s effort and of the support by University and partner companies, which have never missed in these two difficult years. However, the development and the testing of JUNO and IDRAkronos vehicles were not given up, as witnessed by the double first place in the Virtual Technical Inspections with our two vehicles. Vehicles are competitive and we are looking forward to competing on the track again. We are waiting for 2022».

Volkswagen accelerates on the technology of battery cells

The German automotive company Volkswagen and the Chinese company Gotion High-tech have signed a strategic cooperation agreement for building a battery factory at the site of Volkswagen Group Components at Salzgitter.

Herbert Diess, president of the Board of Directors of Volkswagen, explained that together with Gotion High-tech they aim at the progress of the battery cell technology and at becoming one of the first three major “manufacturers in the world”.

In this scenario, Volkswagen foresees to create six gigafactories in Europe with a combined production capacity of 240 gigawatt hour to assure the supply of battery cells.

In May 2020, both partners signed binding agreements that Volkswagen (China) Investment Co. Ltd. will become the largest shareholder in Gotion High-Tech, with 26 percent of the shares, through a buy in of around €1.1 billion.

Thomas Schmall, Group Board Member for Technology and CEO of Volkswagen Group Components: «Gotion High-Tech is an accomplished cell producer recognized for innovative quality work. I look forward to scaling up battery tech together, starting at Salzgitter. With this, we make the central customer-relevant car component even better and e-mobility still more affordable». Mr. Zhen Li, Chairman and CEO of Gotion High-Tech: «With our cutting-edge battery technology and rich experiences in battery manufacturing, Gotion High-Tech will fully support Volkswagen Group’s electrification strategy and together promote the carbon neutral transition by 2050 to completely change human society’s dependence on fossil energy. I firmly believe this cooperation will be a successful model of Sino-European Trade and Economy, as well as of the global new energy strategy».

Electric mobility: the programme to reskill Europe Training

The reskill issue is hotter than ever. Concerning this, good news come from France: EIT InnoEnergy is launching the Academy EBA250 to reskill and to improve the competences of dozen thousands of workers for the battery industry.

As one of the primary players in the ambit of the European Battery Alliance (EBA), France – with three Gigafactories under construction, has a growing need of engineers and specialized technicians. Precisely for this reason, EIT InnoEnergy will guide a platform of education sharing to reduce drastically the costs of reskilling and amelioration of competences. It is a public-private partnership that will face the current gap of competences faced by 800,000 skilled workers requested in the European battery industry by 2025. The training package contains also the skills to face the 4.0 revolution in factories.

EIT InnoEnergy is going to launch urgently its training programme in France and in whole Europe to improve the staff’s competences for the roles of technicians, engineers and researchers who support the electric mobility segment.

Overcoming the traffic with the electric flying bus

Those who live in cities with much traffic have often imagined a flying bust that could transport quickly. A chimera? It seems that this can instead become reality: the United States startup Kelekona has ideated a flying bus able to transport 40 passengers inside cities’ areas or reaching other provinces, too.

The debut is foreseen in New York in 2024, but they already think of replicating it in other metropolis with high rate of traffic jams, like London or Paris.

Concerning the technical characteristics, we know the aircraft – able to reach a speed of 200 miles/hour with a loading capacity of 4.540 kilos will use a 3.6 megawatt interchangeable battery that can be recharged in less than one hour.

Its flying efficiency will be granted by its particular tear shape and two electric fans for the take-off.

The ticket cost is 70 Euros. Expensive or cheap to zero travelling times in cities?

Both motor and jet in the same device

Developed by Sealence spa, DeepSpeed in an innovative electric thruster where jet and electric motor are integrated in the same device, permitting the installation of the whole propulsion out of the hull, directly exposed to the water flow.

The outboard installation allows increasing the space and the comfort onboard and implementing a series of fluid-dynamic innovations, inspired by the aeronautical industry, which allow reaching a much higher efficiency curve than standard motors solutions based on inboard propeller or waterjet.

The target of DeepSpeed technology is accompanying the energy transition of the whole naval sector, thanks to the powertrain that can be full electric or hybrid. Moreover, a SmartBox is available, able to control and to manage all energy flows of the components and of the jets installed on board.

Currently, jets are installed on two laboratory hulls, on boats by partner shipbuilding yards in the range 12–24 metres. Starting from Spring 2022, they will also equip a passenger transport ship featuring 24 metres and 160 pax by Lauro Company, operating in the Gulf of Naples in the Napoli-Ischia-Procida route.

Will the electric car to be assembled “do-it-yourself”, become reality?

The two Ikea and Renault brands were involved in the degree thesis of the young designer Ryan Schlotthauser, who has matched the highlights of the two brands to implement the design of a cheap and sustainable electric car that can be mounted.

The vehicle is called Höga and it is conceived for the saving of those who want an electric car, precisely as in case of furniture: they cost less if they are mounted “do-it-yourself”.

The two-seater car is 1.8 metre high and 2.3 long, with four-wheel drive, for a cost of about 5,000 Euros.

«I wanted to implement something that could be user-friendly and cheap also for those who cannot afford a new expensive car, with an even cheaper solution than a second-hand car. Ikea and Renault are companies that aim at creating sustainable solutions for the mass market» – the designer Schlotthauser commented.

The idea is good and has all papers in order so that the two brands can actually shake their hands. We will see …

How converting a mini-digger into electric

The two protagonist companies are Honda, with its extractable batteries for bikes, and Komatsu, producer of heavy construction vehicles, that are collaborating for the joint development of electrified micro excavators powered by swappable Mobile Power Pack batteries and the establishment of a battery-sharing system for the civil engineering and construction industry.

Through this joint development, the two companies will electrify the Komatsu PC01 micro excavator by equipping it with Honda MPPs and an electrified power unit (eGX). Among various construction machines Komatsu offers, the PC01 is most likely to be used for various functions at worksites near people, trees, flowers and ornamental plants, including pipe-laying, landscaping and agricultural and livestock work. The two companies will strive to introduce the electrified Komatsu PC01 before the end of the current fiscal year, ending March 31, 2022.