The goal that the new managing director, Toshihiro Mibe, has recently communicated and personally defined as “challenging but in line with the brand’s ambitious targets” is reaching a production of fully electric vehicles and nitrogen motors by 2040.

Before, other intermediate steps: the increase up to 40% of the percentage of electric vehicles and double power supply cars, to rise then to 80% in 2035 and to 100% in 2040.

To hit the target, Honda has allocated for its R&D about 5,000 billion yens, accounting for 38 billion Euros, for the next 6 years.

Honda: 100% electric production by 2040

Is an electric air-taxi about to become reality?

It can reach speeds of 320 nodes (593 km/h) and fly up to 500 nautical miles (926 kilometres) with a single battery charge, plus 45 minutes of IFR reserve.

We are speaking of eFlyer 800, the fully electric aircraft by Bye Aerospace, which can host up to 7 passengers and two pilots.

The French Safran Group is collaborating in the development of the eFlyer 800, for both the propulsion system with its “ENGINeUS” motors and for the “GENeUSGRID” energy management system.

At present, we just know the electric craft will be equipped with two motors and it could be able to fly up to 35,000 feet, the equivalent of 10.6 kilometres.

It seems that Quantum Air is planning an air taxi service precisely with these aircrafts.

«The eFlyer 800 – explains George E. Bye, founder and Ceo of the company – is the first all-electric propulsion technology airplane that achieves twin-turboprop performance and safety with no CO2 and extremely low operating costs. This type of remarkable economy and performance is made possible by the electric propulsion system and advanced battery cell technology that results in significantly higher energy densities».

Energy transition: searching for skills

The presence of electronic and electromechanical components in machinery, and therefore in industrial processes, has been rising for some time now in manifold sectors and its growth goes on hand in hand with 4.0 systems. To comply with the trend, it is necessary to create a new generation of skilled professionals

Not only transports: the manufacturing industry in general is concerned by the increasingly massive presence of motors and drives that exploit electric energy instead of the more conventional hydraulic and pneumatic systems.

Besides, it is common opinion that the higher electrification of manufacturing activities or of the building sector might lead – as calculated by Bloomberg NEF in a recent report – to the 60% decrease of greenhouse-effect gases by the half of the century.

Certainly, as highlighted by Enel and Turin Polytechnics in a research presented last December, the secret resides in the will and capability of the various stakeholders of giving birth to an integrated strategy.

What, in other words, the energy provider and the University identify with the expression, the triangle of electricity, at whose vertices we can find renewables, electrification of final consumptions and efficiency of digitalized networks.

Expectations are high: the study estimates that within the next biennium the above-mentioned renewables can represent almost half of total provisioning sources (48%) while from now to 2050 the consumption electrification should reach percentages by 42, 41 and 53% respectively in the ambits of general industry, mobility and residential.

Irrespective of the future possible scenarios, the irremissible matter is that skills are needed to manage them.

And they are not the manifold innovative skills that have been a topical theme since the dawn of Industry 4.0.

The dear old electrotechnics is instead at stake, implemented and refined by a degree in electronic engineering that is in itself synonym of certain employment.

This is the belief – and we will see it hereunder – of the secretary of ANIE Automation and ANIE Energy Marco Vecchio, who however started from other reflections for his interview with Electric Motor Engineering.

Different requirements in the various sectors

«We monitor», Vecchio stated, «the electrification process in mechanics and mechatronics, that is to say how products of this kind converge then into chains like machine manufacturing.

It is an indicator of the trends that enliven the transition from hydraulics to electrical-electromechanical.

From 2013 to 2019, the percentage of electromechanical and electronic components increased by 7% yearly versus the value of machines themselves, also due to the contribution of drives and motors.

For some applications, electromechanics assures more efficiency than hydraulics but this does not mean it is the absolute best option.

It depends on application sectors and fields. In the future, electro-hydraulics grants more energy efficiency and durability, as well as controllability inside a supply chain.

However, it is more correct to say that if in some cases electromechanics is winning, hydraulics and hydraulics-pneumatics is the winner elsewhere».

For instance, «where remarkable performances are imposed – I think of machinery and packaging with their requisites of motion control that mandatorily need a significant contribution by electronics» then «we can affirm the automation injection has quintupled in the around last ten years».

On the contrary, traditional mechanics is still the privileged choice for more basic operations and fields, such as woodworking and textile.

Concerning environmental impacts and consumptions, Marco opportunely preferred making some distinctions.

«There is efficiency enhancement, he pointed out, «and this implies a lower energy demand, although basically electric motors have some of the highest consumptions, no matter what their application field is, from white goods to automotive».

A matter of class

Their subdivision into categories by requirements, the assignment of a precise energy class also to drives and inverters, is one of the aspects at which associations like ANIE have worked in collaboration with institutions. This has resulted in a regulation on eco-drives that will come into force since next July (2021/341).

«In cascade», the number one of ANIE Automation and ANIE Energy added, «we expect regulations about pumps and other parts and on their efficiency, to be read according to a vision of systemic approach and not just for the single component».

Regarding renewables and the European New Green Deal, Vecchio is cautious: «What is contained in the national recovery and resiliency Plan about the green source theme is important.

Nevertheless, the problem is that to concretize the goal of the national Climate-energy Plan, the installation of renewables should increase by six times yearly from now onwards.

We unceasingly dialogue with institutions also in this field, in the attempt of overcoming the hindrances of the well-known NIMBY effect».

The shift to green in its turn needs competences. Therefore, developing them becomes fundamental for the Country system, as well as for the players engaged in various capacities in the energy sector.

An investigation about employment carried out in 2020 revealed that among the 121 students who in 2018 graduated in Electric Engineering at Milan Polytechnics the employment rate was by 96% one year after the degree; in 90% of cases within six months and prevailingly (70%) with permanent contracts.

Commenting the statistics, Vecchio had specified that «electrotechnics should be among the primary choices for a young graduate who approaches University», while «data coming from Italian Universities and associated companies highlight that finding human resources on the market with these skills is instead very difficult».

After some time, the opinion has not changed.

«We are dealing with an important energy and industrial evolution», Vecchio stated, «and we need professionals who can manage it. Digital is strategic and very topical; the so-called soft skills are essential, but if it is true that complexities rise, it is as true that we need people who can face all-round complexities and be problem solving. New professionalisms are precious, provided that we do not forget the tradition of electrotechnics, which has its own specialties, problems and peculiarities. To put it in a joke», he ended, «the knowledge of digital technologies is indispensable but also the acquaintance with a transformer».

(by Roberto Carminati)

Measuring the efficiency of induction motors: what is the actual scenario?

The EU Regulation requires the measurement of efficiency for induction motors, as the surveillance task demanded to the different EU countries. Toward this goal, induction motors’ manufacturers and surveillance authorities should consider various issues related to measurement aspects, as the instrumentation to be adopted and the expression of measurement uncertainty.

by Edoardo Fiorucci, Dept. Industrial and Information Engineering and Economics, University of L’Aquila – Italy

The efficiency measurement is a critical issue in the induction motors market that concerns electric motors manufacturers, suppliers, consumers, and market surveillance authorities.

International Standards and Regulations

In 2009, the European Commission published the Regulation EC 640/2009) [1] concerning requirements for the eco-compatible design of electric motors.

This Regulation applies to single speed, three-phase 50 Hz or 50/60 Hz, squirrel cage induction motor, with 2, 4, and 6 poles, rated voltage up to 1 000 V, rated output power between 0,75 kW and 375 kW, continuous duty operation.

This Regulation does not apply to motors designed to operate wholly immersed in a liquid or integrated into a product (gear, pump, fan, or compressor), brake motors, and motors specifically designed to operate in particular environmental conditions.

This Regulation requires the measurement of efficiency for induction motors, as the surveillance task demanded to the different EU countries.

Toward this goal, induction motors’ manufacturers and surveillance authorities should consider various issues related to measurement aspects, as the instrumentation to be adopted and the expression of measurement uncertainty.

If we take a comprehensive look at the measurement procedures and at some basics of the measurement theory, we need to untangle ourselves among standard uncertainty, combined uncertainty, extended uncertainty, indirect and direct efficiency, and separation of losses tolerances of rated values.

Moreover, the standards seem to be not coordinated, so the operators can be in trouble if they aim at evaluating the efficiency with the related uncertainty, as required.

Two first remarks concerning [1] shall be made about uncertainty and tolerance.

In Annex II, the measurement uncertainty is considered, but only from a qualitative point of view: “…For the purposes of compliance and verification of compliance with the requirements of this Regulation, measurements and calculations shall be made using a reliable, accurate and reproducible method, which takes into account the generally recognised state-of-the-art methods, and whose results are deemed to be of low uncertainty, including methods set out in documents the reference numbers of which have been published for that purpose in the Official Journal of the European Union…”

The difference between the output mechanical power and the input electrical power is due to losses occurring in the motor. The determination of total losses shall be carried out by one of the following methods: measurement of total losses, or determination of separate losses for summation.

Tolerances for manufacturers are introduced in Annex III: “The authorities of the Member State shall test one single unit. The model shall be considered to comply with the provisions set out in this Regulation, if in the nominal motor efficiency (η), the losses (1-η) do not vary from the values set out in Annex I by more than 15 % on power range 0,75-150 kW and 10 % on power range > 150-375 kW…”

Although the effort in regulating the efficiency measurements, from an operative point of view, no numerical goals for the uncertainty are given, resulting in the issues we will discuss at the end of this paper.

The IE efficiency levels in [1] are in the IEC 60034-30-1:2014 Rotating electrical machines – Part 30-1: Efficiency classes of line operated AC motors (IE code) [2]. This standard establishes a set of limit efficiency values based on frequency, number of poles and motor power.

Let us consider the combined effects of [1] and [2], on the reference values for the efficiency, in a real scenario.

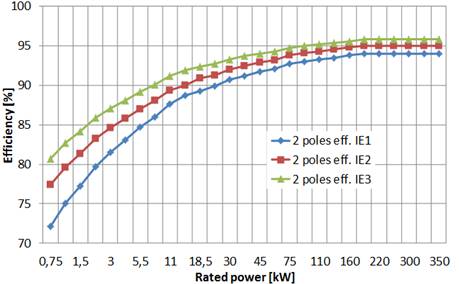

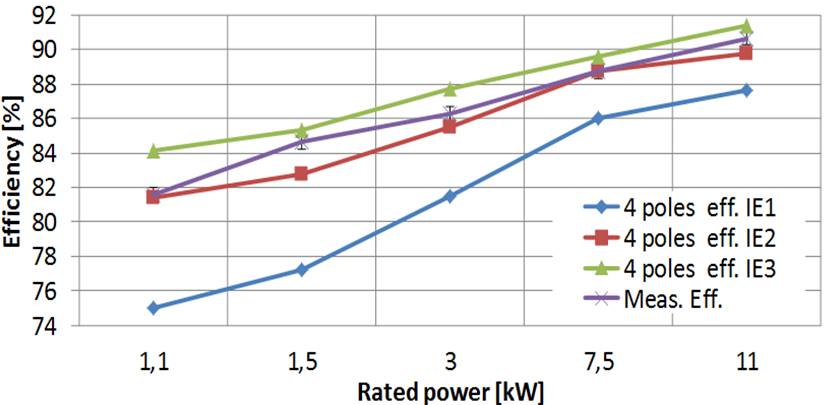

In Fig. 1, the IEC 60034-30-1 efficiency curves for 2-poles induction motors are depicted, for IE1, IE2 and IE3. The effect of the tolerances in [1] leads to the situation in Fig. 2a, with the effects of +/-(15/10) % uncertainty in power losses.

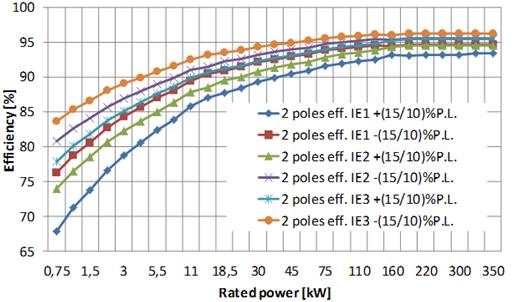

Each curve in Fig.1 should be replaced by a set of two curves, obtained by considering respectively 15 % (induction motors rated power up to and including 150 kW) and 10% (induction motors for rated power induction motors rated power above 150 kW) decrement and increment of the losses related to the IE efficiencies defined by IEC 60034-30-1, according to the rated power.

The obtained six curves are in Fig. 2a and Fig.2b. As a first remark, there are some overlaps because the IE2+(15/10)% curve is lower than IE1-(15/10)%curve, and the IE3+(15/10)%curve is lower than IE2-(15/10)% curve.

This issue could involve some difficulties in classifying an induction motor.

For example, the IE1 and IE2 efficiencies required for 5.5 kW 2 poles induction motors are 84.7% and 87%, respectively; the ranges depicted in Fig.2a are 82.40-86.99 for IE1 and 85.05-88.95 for IE2.

Let’s consider a rated efficiency of 86% declared by the manufacturer.

The considered motor can be simultaneously classified as IE1, because its efficiency is lower than % 86.99, but it can also be rated as IE2 because its efficiency is higher than 85.05%.

A similar problem can be raised for the overlaps of IE2 and IE3 curves. In Fig.2b the obtained curves for the higher rated power range are presented, as an expansion of Fig.2a.

Unfortunately, we have not considered the measurement uncertainty, yet.

Is it mandatory for the operators to evaluate the measurement uncertainty if they are measuring and then guaranteeing the rated efficiency of an induction motor?

Regarding the measurement laboratories, the general requirements for the competence, impartiality, and coherent operation of the laboratories are defined in the ISO / IEC 17025: 2017 [3] standard, which applies to all organizations that carry out laboratory activities but also to regulatory authorities and accreditation bodies.

It states that “testing laboratories shall have and shall apply procedures for estimating the uncertainty of measurement”.

So, we must refer to the uncertainty definition in the Guide ISO/IEC 99:2007, International vocabulary of metrology [4] as the “non-negative parameter characterizing the dispersion of the quantity values being attributed to a measurand, based on the information used.”

Coherently, the measurement result is a “set of quantity values being attributed to a measurand together with any other available relevant information”.

It is probably the most critical and neglected aspect in many experimental procedures in all the technical fields; each measurement result must be expressed as a set of data, not as a single point according to the Euclidean geometry.

Because of the impossibility of having zero uncertainty, we must define our results as a data set, whose width we tend to reduce according to the considered application, desired level of knowledge, budget, and available instrumentation.

In this scenario, the JCGM 100:2008 Evaluation of measurement data — Guide to the expression of uncertainty in measurement [5] is fully applicable because it establishes general rules for evaluating and expressing uncertainty in measurement intended to be applicable to a broad spectrum of measurement procedures.

All the above-mentioned recommendations and standards are to be considered together with the IEC 60034-2-1:2014 Rotating electrical machines – Part 2-1: Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles) [6]; it defines operatively the procedure for the measurement of efficiency.

The test methods are now grouped into preferred methods and methods for field or routine tests.

The preferred methods are presented as methods that allow low uncertainty; for a specific rating and type of machine, only one preferred method is currently defined.

The requirements related to the instrumentation are detailed and refined. Furthermore, the description of all the tests required for each method is explained, in the same sequence needed for the execution of the test itself, with flow diagrams that graphically show the sequence of tests.

As a general remark, it must be noticed an effort to model the effects of many experimental parameters in the evaluation of the different typologies of losses.

Some Experimental Results

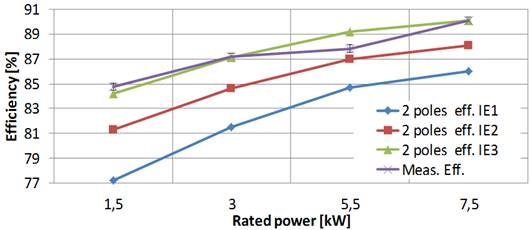

In our Laboratory of Electrical Engineering at the University of L’Aquila, we have been testing several induction motors whose rated power is up to 15 kW (400 V, 50 Hz, TEFC, squirrel-cage), both for research and industrial applications since 1994 (Fig. 3).

Today, our Laboratory is equipped with state-of-the-art instrumentation.

In detail, in this paper, some results about efficiency measurement according to the current version of the standards [5, 6] are presented.

Fig. 4 shows the experimental testing results for IE3 – 2 poles induction motors; the accuracy achieved in efficiency measurement is ± 0,30 % by adopting high accuracy power analyzers and mechanical transducers.

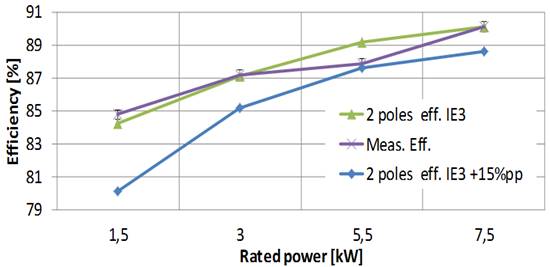

We can observe that only the 5.5 kW motor is below the IE3 efficiency; however, because of the allowed 15% uncertainty in power losses measurement, the manufacturer could correctly classify it as IE3 as suggested by Fig. 5.

This issue is more evident in Fig.6 for the 4-poles induction motors we tested; all of them are characterized by measured efficiency lower than the IE3 curve, which we have measured with experimental uncertainty of +/-0,40%.

Nevertheless, although all of them are below the IE3 curve, they can be classified as IE3 because the manufacturer can take advantage of the allowed 15% uncertainty (Fig.7).

In other words, even if with a high accuracy measurement of efficiency, we demonstrate that an induction motor is below a rated IE efficiency value, the manufacturer could not be criticized because the EC Regulation N. 640/2009, Annex III allows him to perform the efficiency measurement with low accuracy.

Final Remarks and Conclusion

Finally, some remarks about legal issues can be raised in assigning an efficiency class for a measured efficiency.

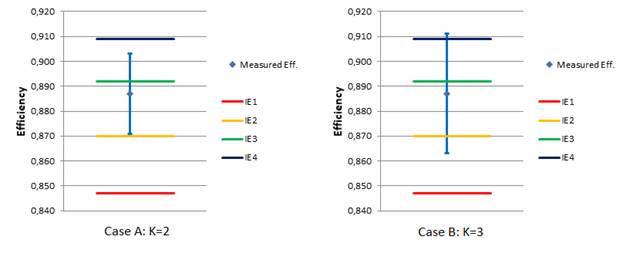

In Fig.8, what is the correct IE class, for a measured efficiency for the case A in which a coverage factor k=2 (95% confidence) is adopted according to the GUM [5]? The motor complies with IE2 requirements because all the data set is over IE2 level.

But I cannot exclude that it is IE3. If we extend the uncertainty, with k=3, (99% confidence), the data set covers 4 IE levels. So, which is the correct IE code for this motor?

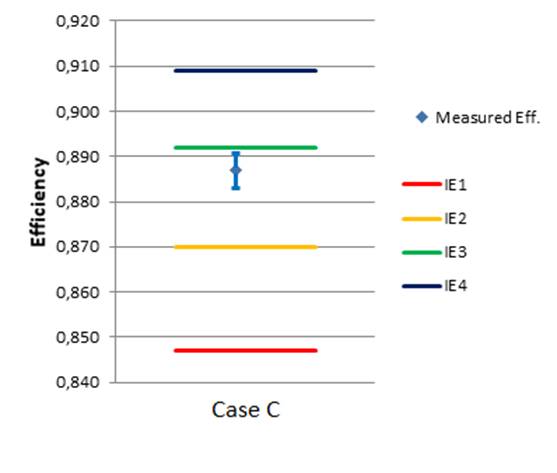

Maybe some additional suggestion of requirements in the international standards can be helpful, starting from the observation that the differences between two contiguous IE levels cannot be thinner than the measurement uncertainty; the desirable scenario is in Fig. 9.

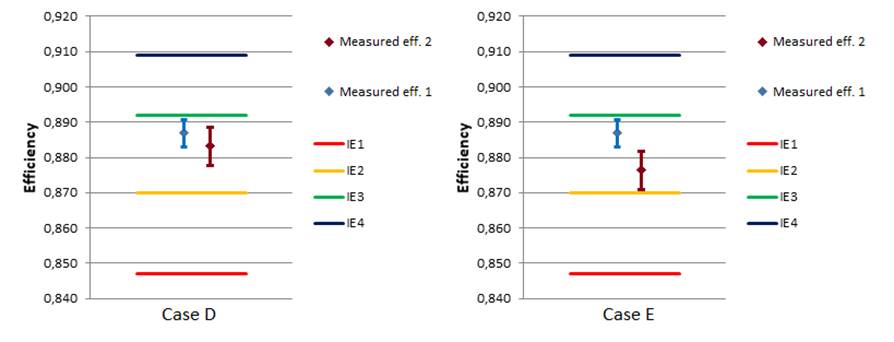

Finally, how are two different data set to be considered if they are different? It is a typical situation in the measurement field. In this case, we must check if they are superimposable.

In Fig. 10, case D shows two sets that are compatible because they are partially superimposable.

Case E in Fig. 10 depicts how the measurements are not compatible, even if they lead to the same IE results because the motor complies IE2 level.

Some references that can be of interest to operators involved in this complex scenario are listed as [8-11].

References

[1] COMMISSION REGULATION (EC) No 640/2009 of 22 July 2009 implementing Directive 2005/32/EC of the European Parliament and of the Council with regard to eco-design requirements for electric motors.[2] IEC 60034-30-1:2014 Rotating electrical machines – Part 30-1: Efficiency classes of line operated AC motors (IE code).

[3] ISO/IEC GUIDE 99:2007 International vocabulary of metrology — Basic and general concepts and associated terms (VIM).

[4] ISO/IEC 17025:2017 General requirements for the competence of testing and calibration laboratories.

[5] SO/IEC Guide 98-3:2008 (JCGM/WG1/100) Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995).

[6] IEC 60034-2-1:2014 Rotating electrical machines – Part 2-1: Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles).

[7] Power Analyzer Accuracy and Basic Uncertainty Calculator R511.xls, 2021, [online] Available: http://tmi.yokogawa.com/.

[8] Rajan, A., Kuang, Y.C., Ooi, M.P.-L., Demidenko, S.N. Measurement uncertainty evaluation: Could it help to improve engineering design? (2019) IEEE Instrumentation and Measurement Magazine, 22 (2), art. no. 8674631, pp. 27-32. DOI: 10.1109/MIM.2019.8674631.

[9] G. Bucci, F. Ciancetta, E. Fiorucci and A. Ometto, “Uncertainty Issues in Direct and Indirect Efficiency Determination for Three-Phase Induction Motors: Remarks About the IEC 60034-2-1 Standard,” in IEEE Transactions on Instrumentation and Measurement, vol. 65, no. 12, pp. 2701-2716, Dec. 2016. DOI: 10.1109/TIM.2016.2599459.

[10] Dubois, C., Leblond, L., Pou, J.-M., Ferrero, A. Covariance evaluation by means of uncertainty assessment (2016) IEEE Instrumentation and Measurement Magazine, 19 (6), art. no. 7777646, pp. 12-18. DOI: 10.1109/MIM.2016.7777646.

[11] Bucci, G., Ciancetta, F., Fiorucci, E., Mari, S., Segreto, M.A. The measurement of additional losses in induction motors: Discussion about the actually achievable uncertainty (2019) Energies, 13 (1), art. no. 78. DOI: 10.3390/en13010078.

Anfia Next Mobility Hackathon: the winner is the public transport of the future

The first edition of the contest ANFIA Next Mobility Hackathon has ended, organized by Components and Car Coachbuilders-Designers Group of ANFIA to give room to the ideas and to the talent of Italian schools’ and Universities’ students in the vision of the mobility of the future.

The Committee of Technical-Scientific Assessment (Comitato di Valutazione Tecnico Scientifica – Cvts) introduced six projects in the range of the selected finalists and the contest was won by Niccolò Casagrande, twenty-one years old student from Iaad in Turin, with a sustainable project for the public transport: Mt_T.

It is modular double-decker tram, designed for the city of Turin as evolution of the so-called light subway. Inspired by Covid-19 emergency, the project aims at a more controlled conditioning due to the downsizing of the cabin and to an attentive development of the vehicle interior space.

«The car and the whole world of means of transport are the focus of radical reviews, in the name of the environmental sustainability and the adoption of new technologies. Design and engineering are the tools to imagine the mobility of the future. With the zero edition of Anfia Next Mobility Hackathon – states Silvio Angori, President of Anfia Components and Car Coachbuilders-Designers Group we intended to establish a channel of direct communication and renewed collaboration with schools and universities and, especially, with the students interested in giving their innovative contribution to the automotive industry».

The risks of the restrictions to steel imports

Clepa – the European Association of Automotive Suppliers fears that the European Commission’s proposal of extending the protection measure that limits steel imports in the EU damages automotive suppliers’ competitiveness and endangers workplaces.

Automotive suppliers, in fact, buy the vast majority of their steel inside the EU and prevailingly import a steel grade for which the European capacity is not enough.

All this with a relevant background: the European automotive industry is responsible for 19% of EU’s iron and steel industry demand.

Automotive suppliers directly employ 1.7 million people across the EU, on top of the 1.2 million people employed in the manufacturing and assembly of vehicle bodies and vehicles. Therefore, continuing protection measures in a time when steelworks are struggling to satisfy the demand and steel prices have reached record levels will necessarily have a negative impact on steel working industries, like automotive.

Clepa’s Secretary General Sigrid de Vries, commented: «Automotive suppliers typically only source steel outside of the EU in cases where there is no sufficient EU production capacity to satisfy the demand for specialised steel. This means that the continuation of the safeguard instrument with only minimal expansion of relevant quota does not serve the interest of the EU economy as a whole and comes at a time where suppliers are struggling to source sufficient volumes of steel in time».

Elica: less “cooking” and more electric motors

Fime is called the motor business unit of Elica Group, operating in the sector of hoods and hobs. Its growth is extremely significant to understand the direction of the electric motor market. In fact, through the preliminary agreement signed between Elica Spa and Electric Motors Company (EMC) and CPS for the purchase of 100% of the share capital of respective companies, Fime has heavily strengthened its presence on the market. EMC and CPS are companies operating on a European scale in the design and production of electric motors, suction systems of household hoods, fans for pellet stoves and medical application motors.

It is an agreement in the development course of Motor business (Fime), through the strengthening of the strategy undertaken with the separation of the Motor division from the Cooking one.

“The takeover of EMC and CPS – explained Luca Barboni, Managing Director of Fime – will generate a significant critical mass that will allow us to have the necessary resources, competences and R&D initiatives to face the European challenges in the matter of energy saving in household appliances and energy transition».

Power electronics: Renault strategic partnership

Power electronics systems of electric and hybrid vehicles will reduce power losses and will improve efficiency, with the consequent great impact on electric vehicles’ autonomy and recharge. The following step? Decrease of batteries’ cost, increase in mileages per recharge and less time of recharge and cost for users.

In their new strategic synergy, Renault Groups– which intend to reach 100% of vehicles by 2030 – and STMicroelectronics will collaborate in the development of efficient, customized and modular components, starting from the understanding of Renault Group’s technical requirements concerning silicon carbide (SiC) devices, gallium nitride (GaN) transistors, with relative packages and modules.

«We are pleased – stated Luca de Meo, CEO of Renault Group – to collaborate with the market leader STMicroelectronics to integrate its advanced power electronics and to develop jointly technologies that can improve the energy capacity of our electric and hybrid vehicles’ batteries and their performance, both on the road and in recharge phase. This partnership assures the future provisioning of key components that will share in the significant 45% reduction of energy losses and in decreasing the cost of the electric powertrain by 30%. This technological collaboration will support us in implementing our ambitious target of democratizing electric vehicles making them, at the same time, affordable and profitable».

The witness of STMicroelectronics, in the person of its President and General Director, Jean-Marc Chéry, is as enthusiastic: «ST is in the forefront in the development of advanced power semiconductors that allow the mobility industry to shift to electrified platforms. Thanks to more energy-efficient products and solutions, based on forefront materials such as the silicon carbide and gallium nitride, we will support Renault strategy dedicated to the next generation of electric and hybrid platforms».

More comfortable yachts with electric fins

Adding a new category of fin stabilizers to its marine equipment range, SKF promises a quieter, more comfortable onboard experience, along with cost-saving and environmental advantages. Spotlights are cast on the powerful, compact non-retractable SKF EFZ type fin stabilizers, designed for luxury yachts measuring 55 metres or longer. They feature a high-torque electric motor that meets the highly dynamic demands of stabilization, whether the vessel is at anchor (zero speed) or under way.

Christopher Schnäckel, Director Fin Stabilizer and Steering Gear, SKF, summarises the significance of this development. “While most fin stabilizers are operated electro-hydraulically, especially on larger yachts, the EFZ system has no hydraulic unit. As a result, its operation is virtually silent. It is also more compact, easier to install and has lower ongoing maintenance and related costs. ”The system takes up less space and has great flexibility for use with the onboard direct or alternating current electrics. Energy consumption is lower, as there are no wasteful conversions between electrical, hydraulic and mechanical devices, which is beneficial both economically and environmentally. The key components of an SKF EFZ fin stabilizer package are its motor, gear unit, fin shaft and mounting unit, together with the fin itself, in sizes ranging up to 12 square metres. The 360-degree constant high torque electrical actuator offers unlimited working angles. Other features include a high-precision SKF bearing system and a VGP (Vessel General Permit) compliant sealing system, which guards against pollution.

Zeiss and Volkswagen: new measuring solution for hairpin stators

It is used for the brand’s ID.3 electric vehicle, among the first vehicles to be designed purely as an electric car. We are talking about new measuring solution for hairpin stators developed by Zeiss and VW.

The hairpins in the stator of the new electric drive, made from coated copper, replace the traditional copper wire coil.

«This approach – explains Philip Kurz, responsible for engine planning and testing at VW – enables high-volume series production, and it also means the engine has more power, while being significantly lighter. However, there remains the challenge of quality assurance because the physical properties of the hairpins push the boundaries of the measuring methods traditionally used in engine construction».

This is why over the past year Zeiss has been working with VW to develop a measuring solution that enables the automaker to manufacture electric cars in large-scale series production.

«Copper is easily deformed, that is why we cannot use tactile methods. Also, it is shiny and semi-transparent, which makes it difficult for optical sensors to detect” – are the words of Pascal Schmidt, part of the quality assurance team.