An engineer from DNCL Technologies publicly talks about this hot topic, presenting the last novelties by the Indian company. DNCL Technologies provides Embedded Product Design and development company, DNCL offers Engineering Product Design Services and Industrial Design, Custom Electronics Product Design, IoT product Development PCB Design, Software Design included firmware and software programming services and RTOS services. «We started using an Artificial intelligence design service, and we are thrilled about the potential impacts of AI’s fusion with electric motors. We know that electric motors are a crucial part of many industrial and commercial applications and their efficient operation is essential to maintaining productivity and reducing costs. By implementing anomaly detection, condition monitoring, and predictive maintenance strategies, businesses can ensure that their motors remain in optimal condition, reducing the risk of downtime and costly repairs and extending the lifespan of their equipment».

About anomaly detection, «AI is our motor whisperer, picking up on those subtle cues we may miss. Abnormal vibrations, temperature spikes, unusual power consumption—all signs of underlying problems that left unchecked, could lead to severe damage or motor failure. Condition Monitoring is the round-the-clock guardian, keeping a watchful eye on key performance indicators like temperature, vibration, and power consumption. Machine learning models can detect those slight shifts in motor behaviour, hinting at potential issues».

Predictive Maintenance takes condition monitoring up a notch. By using advanced analytics and machine learning algorithms, AI can predict when maintenance will be needed. Imagine sensors installed in the motor system, collecting data on parameters such as vibration, temperature, current, pressure, and magnetic fields. This data is then processed and analysed to identify anomalies or patterns that could flag potential issues. Finally, by comparing historical motor performance data with real-time sensor readings, predictive maintenance systems can detect anomalies and predict when critical components may fail.

Artificial intelligence for the creation of electric motors

CITraMS for transport and sustainable mobility

The topic of sustainable mobility has become a heritage of the sensitivity acquired in recent times by public opinion and is almost unanimously considered central to the processes of territorial and especially urban development.

Complexity is inherent in the concept of sustainability to be understood as a volume of overlapping among environmental, social and economic spheres. It is necessary to be aware that moving people or goods in space is an articulated and complex function since it implies the involvement of users’ needs with acquired behaviors, territorial assets, different transport systems, technological devices, physical and regulatory constraints, etc.

The transportation sector in particular and the mobility sector in general have a large impact on health and human life, so anything that improves people’s health and protects human life should be counted among the sustainable initiatives. From this point of view, the sustainable mobility can only be analyzed following the logic of complexity through a systemic and multidisciplinary approach based on an adequate level of knowledge, analytical and numerical studies, simulation models for the critical evaluation of all effects.

The Research center

With the intent to contribute to addressing the complex issue mentioned above, in 2019 the University of L’Aquila has established the Interdepartmental Research Center for Transport and Sustainable Mobility (CITraMS) which involves the 7 Departments of the University, public Bodies, transport Companies and sever- al national and international ex- perts in the field of transportation. The Abruzzo Region and TUA, the Unique Abruzzo Public Transport Company, have joined this initiative that is unique in the Italian panorama.

The Center was therefore born with a high both territorial and international vocation and with a transversal scientific approach involving several fields such as engineering, computer science, mathematics, physics, chemistry, medical-neuroscientific science and humanistic disciplines, as illustrated in the Fig 1.

Themes and objectives

CITraMS promotes and coordinates interdisciplinary research, technology transfer and dissemination activities in the transportation (passenger and freight) and sustainable mobility sectors, with particular regard to:

• Planning of transport infrastructures and related socio-economic and management aspects

• Theoretical analysis and modeling of demand, transport supply and their

interaction

• Advanced transport systems and technological innovation of their components

• Innovative propulsion systems with low impact and technological innovation of their components

• Interaction between transportation, physical/social environment, education,

health, disability and aging.

The main objectives of the CITraMS are focused on:

• Promoting and disseminating the culture of sustainable mobility and knowledge in the field of transport in several contexts

• Promoting the interdisciplinary nature of the issues of analysis, the proposition

and experimentation connected to the different transport systems and methods and to their social, economic and environmental impacts

• Triggering partnership processes between universities, research centers, public bodies

and companies in support of strategic sector research

• Fostering processes and socio-economic dynamics aimed to generating innovative entrepreneurship in the local, national and international context

• Supporting the technology transfer process in the sector

• Promoting agreements and promoting relationships with public bodies and companies to generate direct and indirect attractiveness and investments

• Developing national and international cooperation networks

New technologies for free emissions transportation systems

CITraMS pays great attention to research activities focused on the development and applications of new technologies for emission-free mass transit systems.

Listed below are some of the research and technology development activities that CITraMS members lead in the field of free emissions transportation systems:

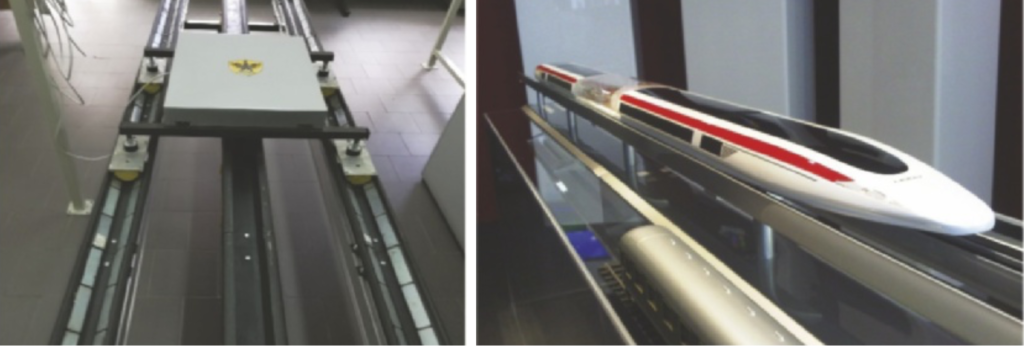

a) Magnetic levitation transport system with high temperature superconducting suspension (Fig. 2)

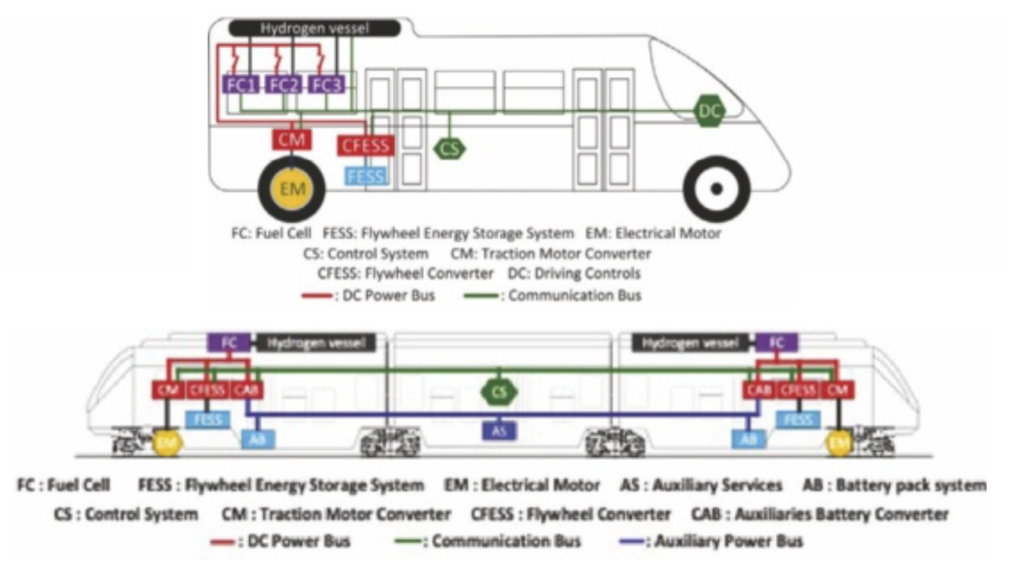

b) Rail (Fig. 3a) and road (Fig. 3b) vehicles with emission-free energy cycle powered by hydrogen Fuel Cell and Flywheel Energy Storage System (FESS) power unit

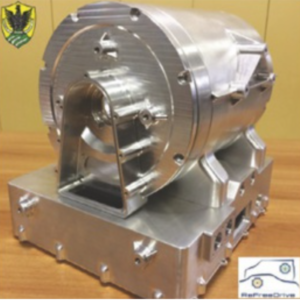

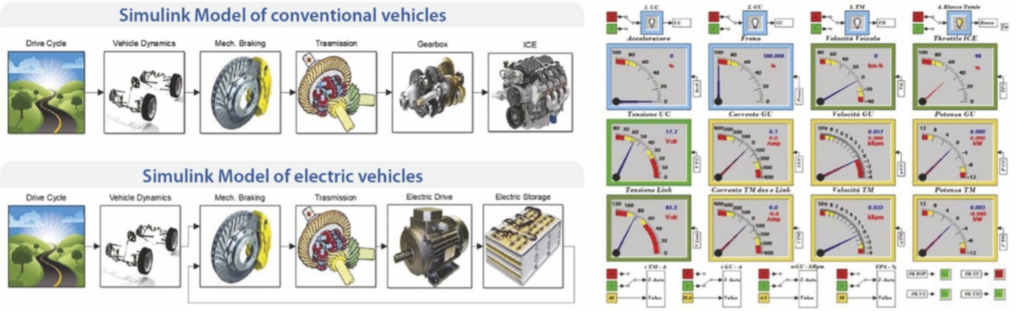

c) Power-trains for full electric vehicles (Fig. 4)

d) Innovative propulsion systems design, testing, optimization and control (Fig.5).

(by Gino d’Ovidio, director of CITraMS)

Customized robotics for the assembly operations of electric motors

Among the many successful projects recently installed by SIR Robotics, company that stands out in industrial automation, we can mention those related to the assembly of electric motors for e-mobility, compressors and heating convectors, welding of components for logistics warehouses and components for solid-liquid separation systems.

Besides, the company’s activities include the assembly of the powertrain group components, electric motor assembly, gearmotor assembly, assembly of electromechanical cooling groups, assembly of components for the mechanical industry and assembly of components for the electromechanical industry. Through the in-house Mechanical and Electronic Engineering, the idea for the electric motor assembly system turns into design and becomes project, scheme, layout, code. Everything is only and exclusively studied for the specific customer, shaped according to its requirements, rationalized and engineered, starting from a white sheet.

An electric vehicle helipad is coming to downtown Manhattan

The major of New York Eric Adams, the president and managing director of the New York City Economic Development Corporation (NYCEDC) Andrew Kimball have recently taken the first steps to implement a hub unique of its kind for sustainable transports and deliveries. It is a helipad in New York, precisely downtown Manhattan (DMH).

This opens the possibility of electric taxis for the transport of passengers from the airport to downtown and of electric drones also for home deliveries. It seems that in less than two years, through drones, it will be possible to decrease the urban traffic and to halve travel times, with the target of reducing the atmospheric pollution. Just think that it would take only 7 minutes to reach Manhattan downtown from the JFK airport in New York. This direction is pursued by United States startups such as Joby Aviation and Volocopter that have started tests for flying taxis for passengers’ transport.

How contrasting shaft current problems

The big player ABB is casting its spotlights on what are shaft currents and how to protect AC motor. Over time, continual arcing within an electric motor will cause damage to the surface of the bearing raceway resulting in vibration and heat, loud operating noises, and eventually motor failure.

Fortunately, there are several practical and easy ways to mitigate shaft current issues. Using proper VFD cables and bearing protection will help protect the life of your motor and driven equipment.

Brush protection rings and insulated bearings are just a few ways to mitigate shaft currents that can harm the motor and equipment. Including these preventive measures will ensure peace of mind and increase the reliability of your inverter duty motor performance.

UK project for electric aircrafts

New resources join the biennial project of the Aerospace Technology Institute (ATI) and Innovate UK known as InCEPTion, Integrated Flight Control, Energy Storage and Propulsion Technologies for Electric Aviation.

The English Drive System Design has in fact become key partner of the project as consulting company that will develop the electric motor and the power electronics for a unique highly integrated propulsion module suiting a range of aircrafts.

The project is a joint investment of Government and industry to maintain and enhance the competitive edge of United Kingdom in the civil aerospace design and production. InCEPTion, guided by Blue Bear Systems Research, will in fact develop a modular electric propulsion unit for manned and unmanned aircrafts, vertical take- off and landing (VTOL) and conventional take-off and landing aircrafts (CTOL) for 30 passengers maximum.

In Berlin the new engineering centre for Bugatti Rimac

In the German capital, a new design and engineering hub will be established and it will operate under a new German subsidiary called Bugatti Rimac GmbH. Berlin is a young and sparkling city, able to fuel technological start-ups, an epicentre for artists and designers.

However, the automotive company’s headquarters will always remain in Zagreb, with the vast majority of employees and a future expansion in Croatia.

It seems that some job positions are already open: Concept Chief Engineer, Head of High-Voltage Systems and Components, Head of Fine Mechanics and design roles with specific focus on interiors, exteriors and VR.

Adriano Mudri, previously design director of Rimac Automobili, will be appointed design director of a future sister company of Rimac focused on mobility, which will take care of developing state-of-the-art vehicles, which will be successively revealed.

«Bugatti Rimac GmbH – stated its CEO Mate Rimac – represents a new exciting business expansion. This new branch will be deeply involved in many new exciting hypercar designs we are looking forward to sharing with the world. Our team is expanding day by day and Bugatti Rimac GmbH represents an opportunity for the best in the sector to join us, to prove their skills and to be part of a company that is redefining the hypercar».

Vatican chooses the electric mobility

Volkswagen is the partner chosen to support the Vatican City State in its transition towards the sustainable mobility: the manufacturer will deliver slightly less than 40 full electric vehicles of Volkswagen ID. family, which range from ID.31 to ID.4 and ID.5. Mobility is at the core of a specific programme called “Ecologic conversion 2030”, which aims at reducing the CO2 footprint of the State’s vehicle fleet. To reach this target, the existing vehicles must be gradually replaced by electric ones, to make the whole fleet neutral from the point of view of CO2 emissions by 2030.

Through Volkswagen Financial Services, the automotive brand will supply the Vatican City State with a fleet of cars from the beginning of 2024. In successive phases, a growing number of zero-emission vehicles will be delivered also by Volkswagen Group brands, until the complete replacement of the whole fleet by 2030.

“The fleet electrification is becoming more and more important on a global scale. In future perspective, offering the drive of our ID. also to Vatican’s employees is a great achievement and honour for Volkswagen and highlights the attractiveness of full electric ID. models” stated Imelda Labbé during the delivery of vehicles in Vatican.

A new generation of high-performance e-motor, for braking systems and cars’ traction

Developing a new generation of high-performance electric motors, for both braking systems and cars’ traction, was the goal of Inproves pilot project, started in 2017, whose head company is Brembo, top player multinational in the production of systems for braking plants. Together with it, the partners eNovia, Mako-Shark, Magnenti Marelli, Motorsport, Peri, Milan Polytechnics, – Engineering and Energy Departments, MDQuadro, UTPVision and University of Bergamo have collaborated in the initiative.

We are in the ambit of the 2014-2020 operational regional programme, co-funded by Lombardy Region with European funds.

Inproves has provided for an integration of product and process for the implementation of road vehicles’ electric motors, to develop brushless electric motors (Permanent Magnet Machines-PMM) for both braking systems and for traction and energy recovery.

Such PMM are conceived simultaneously with the manufacturing process, based on Industry 4.0 paradigms, that is to say the complete digitalization of the production process, for the control and the management of plants, of processes and of logistic-productive flows.

Brembo and Marelli, with the support of Milan Polytechnics, have developed the mechanical and electromagnetic design of two different motor typologies for braking and traction systems.

Marelli has implemented a new high-efficiency traction motor, whereas Brembo has started the production of two motors’ prototypes for braking systems of different sizes, through a new digitalized assembling line, collaborating also with e-Novia, the Business Factory specialized in deep technologies, to develop a demonstrator of a new concept of integrated sensor for the control of the braking system. More in detail, concerning e-Novia, it is the design and testing of a magnetic sensor for measuring the rotor’s absolute position in a BLDC motor, with advantages in terms of assembling and performances.

«With INPROVES, today an ambitious challenging project is ending,” stated Alessandro Ciotti – Chief R&D Officer of Brembo, “which has involved the pre-industrial development of a new family of products and technical solutions in the ambit of the sustainable mobility of the future, whose priority targets are the adoption of more efficient, automated and connected vehicles».

In Canada 100% electric seaplanes

Completely composed by seaplanes, the Canadian airline Harbour transports over half million passengers yearly and it has recently announced it is going to convert all aircrafts of its property, equipping them with electric motors. Through an agreement with the company magniX that will supply propulsors, Harbour Air will therefore go down in history as one of the first fully electric airline companies.

The protagonist motor of this change is magni500 and the pioneer aircrafts of this installation are DHC-2 de Havilland Beaver. The motor develops 750 horsepower with an autonomy of more than one hour. Besides, considering that the vast majority of flights performed by Harbour Air last around half an hour, it is an excellent opportunity in both economic and environmental terms. Maintenance will be facilitated by a more user-friendly management of motors, with compulsory check cycles in longer times than with standard motors.

When will the transition from traditional to electric occur? It seems that it might even be accomplished by 2021, carrying out all twelve routes currently in operation.