In the Engineering Department of Palermo University, RPLab – Rapid Prototyping Laboratory is the laboratory where they design and implement prototypes of electronic power converters, control, conditioning and interface boards for research ambits in automotive, industrial and net-connected fields. Its interior hosts forefront LPKF Laser & Electronics machines. Managers have recently published a video that shows how is created an interface screen for an electric drive control based on a multi-level inverter and a permanent magnet brushless motor.

A showcase that accompanies the proposal of visiting the laboratory, which opens its doors to all to show its excellence and which is at the service of the Rapid Prototyping Laboratory graduation course.

The RPLab laboratory opens the doors

The new innovative battery by Stellantis that combines an inverter and a charger

After four years of intense projects and severe simulations, a team of 25 specialists who include engineers and researchers of Cnrs, the French National Centre of Scientific Research, has revealed a battery system known as Ibis (Integrated System of Intelligent Batteries). Ibis is supported by the Future Investment Plan, managed by Ademe (the French agency for the environment and the energy management) and coordinated by Stellantis. The primary participants in the project include Saft (TotalEnergies Group), E2CAD and Sherpa Engineering, together with the research laboratories of Cnrs and Institut Lafayette.

The specificity of this innovation resides in its design: the battery combines an inverter and a charger, notably increasing the efficiency and the longevity of batteries for electric vehicles. Moreover, this new configuration decreases costs and at the same time frees inner space in the vehicle.

Ibis is not only a product, but a real project that started in summer 2022, a system that changes the way according to which conversion boards are positioned as close as possible to the elements of the lithium-ion battery: a strategic position that allows the battery to produce directly alternate current for the electric motor.

Ibis has the potential to reduce the weight and the manufacturing costs of electric vehicles and to widen the range of available functions. From the point of view of the stationary energy, Saft provides for offering turnkey plants that enable a more efficient energy use, decreasing the environmental impact. Ibis battery by Stellantis also offers a simplified maintenance and an enhancement of plants.

Fraunhofer IPA: towards the “repair of motors”

20In the e-bike market, one of the hottest problems is the failure of the electric motor. Nowadays, the replacement of the unit occurs in the vast majority of cases. In the light of this situation, the team from Fraunhofer IPA Institute, headed by the project manager Jan Koller, wondered whether it was possible to develop a more circular motor model, providing for the repair instead of the replacement. The first step consisted in the implementation of 3D models and in the creation of spare parts with 3D additive printing, testing the various types of materials and manufacturing over 120 components in 20 different materials. Motors were then reassembled and subjected to severe tests on bench and with real load. Results? The motors so overhauled have offered the same performances as newly-manufactured motors, and with the same guarantee. What is more difficult, economically speaking, is establishing the breakeven point in the motor reconditioning business.

Digital twins and electric motors, studies and startups to innovate

A global research by Altair, American company specialized in computational science and in Artificial Intelligence (AI), involved over 2,000 professionals from 11 sectors in 10 Countries on the Digital Twin theme. Results describe the widespread use of the Digital Twin in numerous fields, with the automotive in the first place, to make cars more efficient and sustainable and to shorten the time to market of electric vehicles. The automotive industry is the second major user of the Digital Twin technology (76%), just preceded by manufacturers of heavy equipment. The primary highlights would reside in the energy saving and in the more efficient use of resources (time, work hours and raw materials), with fewer rejects and wastes. Digital Twin solutions decrease, for instance, the material waste, through simulations and tests carried out during the design process. In this way, the number of physical prototypes needed before the production start is reduced.

Concerning the electrification of motors, Andrea Benedetto, CEO of Altair, stated: «The issue is always optimization. The challenge is to succeed in designing vehicles that weigh less and motors with higher efficiencies for specific use missions. In this way, performances improve and consumptions decrease. In this ambit as well, the Digital Twin can make the difference since development costs. It allows a faster and more efficacious process, driven by optimization».

Concerning this, a recent Italian example is Newtwen, a Padua startup set up by a team of three young researchers and two professors of the local University who have developed a software platform that generates extremely accurate virtual replications of physical systems, able to integrate them inside systems themselves to improve the performances, the longevity and the reliability, without the need of adding new electronic hardware components. The declared target is revolutionizing the future of the mobility and of the sustainable energy by decreasing the environmental impact and the consumptions of electric

Audi, powertrain with three electric motors

Audi’s will of further strengthening its electric expansion has led to the development of the S versions of Audi e-tron and Audi e-tron Sportback, which adopt three electric motors, two at the rear axle, able to supply an overall maximum power of 503 HP. It is an absolute premiere for mass-produced models.

The electric four-wheel drive avails itself of the innovative electric torque vectoring function with active variable distribution of the torque on the rear axle. Reactivity, performance and feeling while driving reach a new dimension.

503 HP and 973 Nm of torque allow shifting from 0 to 100 km/h in 4.5 seconds.

Compact and light Triumph, thanks to the electric motor

Triumph has announced its first full electric motorbike: Project TE-1 Prototype.

The project is fruit of the synergy among various companies: Williams, which takes care of developing the battery, Integral Powertrain Ltd, for the motor design, and Wmg, for simulations and tests.

The British motorbike producer has recently ended the phase 2 of the TE-1 project, with interesting results that anticipate the vehicle’s real potentialities.

It seems in fact that the motor unit with integrated inverter will allow the electric bike to reach a power of 30 kW, corresponding to about 180 HP.

The design provides for straight lines and battery pack and motor hidden under superstructures, with the charging socket positioned where the tank is usually housed.

«One of the most influential factors on handiness and performances of a motorbike is its mass. The weight will be just 10 kg and we have focused – added Andrew Cross, Chief Technical Officer of Integral Powertrain Ltd – on making a radical change in the design of motor and inverter, this provides a more compact and lighter product than any other unit currently available on the market».

The target, in the successive 3 and 4 phases, is turning the proof into a real motorbike. There is not a date, but lovers are impatient worldwide.

CITraMS for transport and sustainable mobility

The topic of sustainable mobility has become a heritage of the sensitivity acquired in recent times by public opinion and is almost unanimously considered central to the processes of territorial and especially urban development.

Complexity is inherent in the concept of sustainability to be understood as a volume of overlapping among environmental, social and economic spheres. It is necessary to be aware that moving people or goods in space is an articulated and complex function since it implies the involvement of users’ needs with acquired behaviors, territorial assets, different transport systems, technological devices, physical and regulatory constraints, etc.

The transportation sector in particular and the mobility sector in general have a large impact on health and human life, so anything that improves people’s health and protects human life should be counted among the sustainable initiatives. From this point of view, the sustainable mobility can only be analyzed following the logic of complexity through a systemic and multidisciplinary approach based on an adequate level of knowledge, analytical and numerical studies, simulation models for the critical evaluation of all effects.

The Research center

With the intent to contribute to addressing the complex issue mentioned above, in 2019 the University of L’Aquila has established the Interdepartmental Research Center for Transport and Sustainable Mobility (CITraMS) which involves the 7 Departments of the University, public Bodies, transport Companies and sever- al national and international ex- perts in the field of transportation. The Abruzzo Region and TUA, the Unique Abruzzo Public Transport Company, have joined this initiative that is unique in the Italian panorama.

The Center was therefore born with a high both territorial and international vocation and with a transversal scientific approach involving several fields such as engineering, computer science, mathematics, physics, chemistry, medical-neuroscientific science and humanistic disciplines, as illustrated in the Fig 1.

Themes and objectives

CITraMS promotes and coordinates interdisciplinary research, technology transfer and dissemination activities in the transportation (passenger and freight) and sustainable mobility sectors, with particular regard to:

• Planning of transport infrastructures and related socio-economic and management aspects

• Theoretical analysis and modeling of demand, transport supply and their

interaction

• Advanced transport systems and technological innovation of their components

• Innovative propulsion systems with low impact and technological innovation of their components

• Interaction between transportation, physical/social environment, education,

health, disability and aging.

The main objectives of the CITraMS are focused on:

• Promoting and disseminating the culture of sustainable mobility and knowledge in the field of transport in several contexts

• Promoting the interdisciplinary nature of the issues of analysis, the proposition

and experimentation connected to the different transport systems and methods and to their social, economic and environmental impacts

• Triggering partnership processes between universities, research centers, public bodies

and companies in support of strategic sector research

• Fostering processes and socio-economic dynamics aimed to generating innovative entrepreneurship in the local, national and international context

• Supporting the technology transfer process in the sector

• Promoting agreements and promoting relationships with public bodies and companies to generate direct and indirect attractiveness and investments

• Developing national and international cooperation networks

New technologies for free emissions transportation systems

CITraMS pays great attention to research activities focused on the development and applications of new technologies for emission-free mass transit systems.

Listed below are some of the research and technology development activities that CITraMS members lead in the field of free emissions transportation systems:

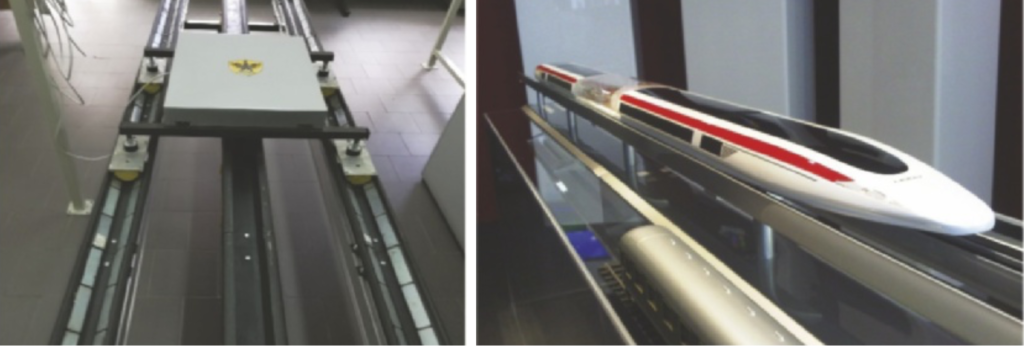

a) Magnetic levitation transport system with high temperature superconducting suspension (Fig. 2)

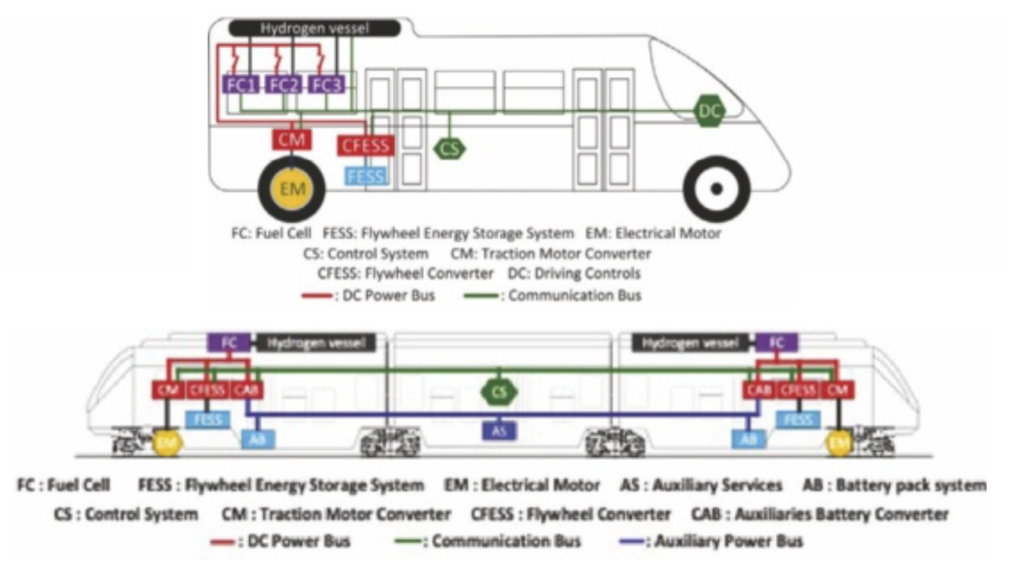

b) Rail (Fig. 3a) and road (Fig. 3b) vehicles with emission-free energy cycle powered by hydrogen Fuel Cell and Flywheel Energy Storage System (FESS) power unit

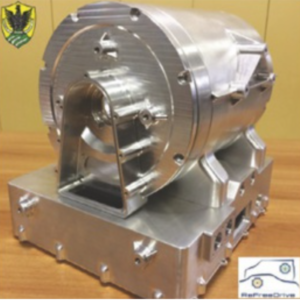

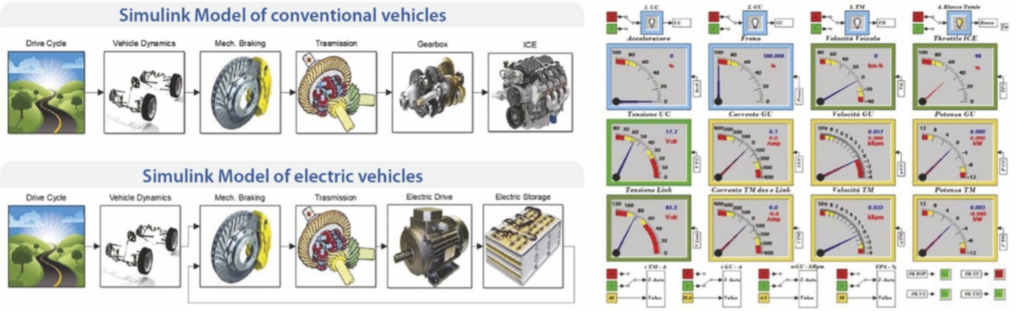

c) Power-trains for full electric vehicles (Fig. 4)

d) Innovative propulsion systems design, testing, optimization and control (Fig.5).

(by Gino d’Ovidio, director of CITraMS)

UK project for electric aircrafts

New resources join the biennial project of the Aerospace Technology Institute (ATI) and Innovate UK known as InCEPTion, Integrated Flight Control, Energy Storage and Propulsion Technologies for Electric Aviation.

The English Drive System Design has in fact become key partner of the project as consulting company that will develop the electric motor and the power electronics for a unique highly integrated propulsion module suiting a range of aircrafts.

The project is a joint investment of Government and industry to maintain and enhance the competitive edge of United Kingdom in the civil aerospace design and production. InCEPTion, guided by Blue Bear Systems Research, will in fact develop a modular electric propulsion unit for manned and unmanned aircrafts, vertical take- off and landing (VTOL) and conventional take-off and landing aircrafts (CTOL) for 30 passengers maximum.

Here is the study to extract magnets from electronic waste

The prestigious Bentley Motors brand aims at more sustainable electric motors and, concerning this, it has announced a specific triennial technological study. It is called RaRE (Rare-earth Recycling for E-machines) and will be based on the work accomplished by the University of Birmingham in the ideation of a method to extract magnets from electronic wastes. The goal is reusing the magnetic material extracted to implement new recyclable magnets to be integrated inside tailored auxiliary motors. Even more sustainability will be assured by the fact that the motors tailor-made through this method allow minimizing the complexity of some manufacturing phases, meanwhile supporting the development of the supply chain of the United Kingdom for both mass-production components and for small batches.

“While we are speeding up the electrification race, offering only hybrid or electric vehicles within 2026 and full electric within 2030, it is important to focus on each aspect of the vehicle sustainability, including sustainable provisioning methods of materials and components. RaRE promises a radical change of the electric recyclability, providing a source of low-voltage motors really tailored for a series of different applications and we are confident that results will provide a support for completely sustainable electric drives “. This is the witness by Matthias Rabe, member of the Board of Directors of Bentley Motors.

Man can fly. Here is the wingsuit with electric motor

The first test of a revolutionary wingsuit, which allows man “to fly” has been recently held in Austria. How? Thanks to a 15 kW electric motor that powers two 7.5 kW 25,000 rpm turbines.

The wingsuit, which allows flying at 300 km/h, is called Electrified Wingsuit and it is the fruit of a project funded by Bmw, whose protagonist is the designer Peter Salzman.

The test took place along the Alpine chain Die drei Brüder, where the man in the wingsuit jumped from a helicopter at three thousand metres of altitude.

At present, it is just a prototype, will it really be a possibility for all in the future?