The EU Regulation requires the measurement of efficiency for induction motors, as the surveillance task demanded to the different EU countries. Toward this goal, induction motors’ manufacturers and surveillance authorities should consider various issues related to measurement aspects, as the instrumentation to be adopted and the expression of measurement uncertainty.

by Edoardo Fiorucci, Dept. Industrial and Information Engineering and Economics, University of L’Aquila – Italy

The efficiency measurement is a critical issue in the induction motors market that concerns electric motors manufacturers, suppliers, consumers, and market surveillance authorities.

International Standards and Regulations

In 2009, the European Commission published the Regulation EC 640/2009) [1] concerning requirements for the eco-compatible design of electric motors.

This Regulation applies to single speed, three-phase 50 Hz or 50/60 Hz, squirrel cage induction motor, with 2, 4, and 6 poles, rated voltage up to 1 000 V, rated output power between 0,75 kW and 375 kW, continuous duty operation.

This Regulation does not apply to motors designed to operate wholly immersed in a liquid or integrated into a product (gear, pump, fan, or compressor), brake motors, and motors specifically designed to operate in particular environmental conditions.

This Regulation requires the measurement of efficiency for induction motors, as the surveillance task demanded to the different EU countries.

Toward this goal, induction motors’ manufacturers and surveillance authorities should consider various issues related to measurement aspects, as the instrumentation to be adopted and the expression of measurement uncertainty.

If we take a comprehensive look at the measurement procedures and at some basics of the measurement theory, we need to untangle ourselves among standard uncertainty, combined uncertainty, extended uncertainty, indirect and direct efficiency, and separation of losses tolerances of rated values.

Moreover, the standards seem to be not coordinated, so the operators can be in trouble if they aim at evaluating the efficiency with the related uncertainty, as required.

Two first remarks concerning [1] shall be made about uncertainty and tolerance.

In Annex II, the measurement uncertainty is considered, but only from a qualitative point of view: “…For the purposes of compliance and verification of compliance with the requirements of this Regulation, measurements and calculations shall be made using a reliable, accurate and reproducible method, which takes into account the generally recognised state-of-the-art methods, and whose results are deemed to be of low uncertainty, including methods set out in documents the reference numbers of which have been published for that purpose in the Official Journal of the European Union…”

The difference between the output mechanical power and the input electrical power is due to losses occurring in the motor. The determination of total losses shall be carried out by one of the following methods: measurement of total losses, or determination of separate losses for summation.

Tolerances for manufacturers are introduced in Annex III: “The authorities of the Member State shall test one single unit. The model shall be considered to comply with the provisions set out in this Regulation, if in the nominal motor efficiency (η), the losses (1-η) do not vary from the values set out in Annex I by more than 15 % on power range 0,75-150 kW and 10 % on power range > 150-375 kW…”

Although the effort in regulating the efficiency measurements, from an operative point of view, no numerical goals for the uncertainty are given, resulting in the issues we will discuss at the end of this paper.

The IE efficiency levels in [1] are in the IEC 60034-30-1:2014 Rotating electrical machines – Part 30-1: Efficiency classes of line operated AC motors (IE code) [2]. This standard establishes a set of limit efficiency values based on frequency, number of poles and motor power.

Let us consider the combined effects of [1] and [2], on the reference values for the efficiency, in a real scenario.

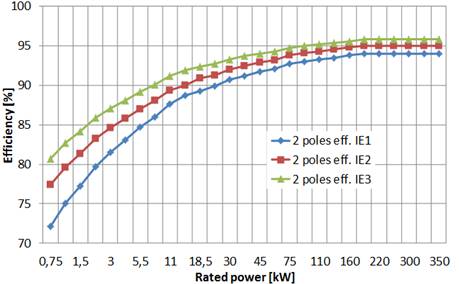

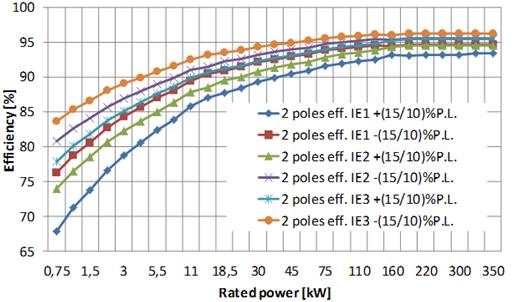

In Fig. 1, the IEC 60034-30-1 efficiency curves for 2-poles induction motors are depicted, for IE1, IE2 and IE3. The effect of the tolerances in [1] leads to the situation in Fig. 2a, with the effects of +/-(15/10) % uncertainty in power losses.

Each curve in Fig.1 should be replaced by a set of two curves, obtained by considering respectively 15 % (induction motors rated power up to and including 150 kW) and 10% (induction motors for rated power induction motors rated power above 150 kW) decrement and increment of the losses related to the IE efficiencies defined by IEC 60034-30-1, according to the rated power.

The obtained six curves are in Fig. 2a and Fig.2b. As a first remark, there are some overlaps because the IE2+(15/10)% curve is lower than IE1-(15/10)%curve, and the IE3+(15/10)%curve is lower than IE2-(15/10)% curve.

This issue could involve some difficulties in classifying an induction motor.

For example, the IE1 and IE2 efficiencies required for 5.5 kW 2 poles induction motors are 84.7% and 87%, respectively; the ranges depicted in Fig.2a are 82.40-86.99 for IE1 and 85.05-88.95 for IE2.

Let’s consider a rated efficiency of 86% declared by the manufacturer.

The considered motor can be simultaneously classified as IE1, because its efficiency is lower than % 86.99, but it can also be rated as IE2 because its efficiency is higher than 85.05%.

A similar problem can be raised for the overlaps of IE2 and IE3 curves. In Fig.2b the obtained curves for the higher rated power range are presented, as an expansion of Fig.2a.

Unfortunately, we have not considered the measurement uncertainty, yet.

Is it mandatory for the operators to evaluate the measurement uncertainty if they are measuring and then guaranteeing the rated efficiency of an induction motor?

Regarding the measurement laboratories, the general requirements for the competence, impartiality, and coherent operation of the laboratories are defined in the ISO / IEC 17025: 2017 [3] standard, which applies to all organizations that carry out laboratory activities but also to regulatory authorities and accreditation bodies.

It states that “testing laboratories shall have and shall apply procedures for estimating the uncertainty of measurement”.

So, we must refer to the uncertainty definition in the Guide ISO/IEC 99:2007, International vocabulary of metrology [4] as the “non-negative parameter characterizing the dispersion of the quantity values being attributed to a measurand, based on the information used.”

Coherently, the measurement result is a “set of quantity values being attributed to a measurand together with any other available relevant information”.

It is probably the most critical and neglected aspect in many experimental procedures in all the technical fields; each measurement result must be expressed as a set of data, not as a single point according to the Euclidean geometry.

Because of the impossibility of having zero uncertainty, we must define our results as a data set, whose width we tend to reduce according to the considered application, desired level of knowledge, budget, and available instrumentation.

In this scenario, the JCGM 100:2008 Evaluation of measurement data — Guide to the expression of uncertainty in measurement [5] is fully applicable because it establishes general rules for evaluating and expressing uncertainty in measurement intended to be applicable to a broad spectrum of measurement procedures.

All the above-mentioned recommendations and standards are to be considered together with the IEC 60034-2-1:2014 Rotating electrical machines – Part 2-1: Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles) [6]; it defines operatively the procedure for the measurement of efficiency.

The test methods are now grouped into preferred methods and methods for field or routine tests.

The preferred methods are presented as methods that allow low uncertainty; for a specific rating and type of machine, only one preferred method is currently defined.

The requirements related to the instrumentation are detailed and refined. Furthermore, the description of all the tests required for each method is explained, in the same sequence needed for the execution of the test itself, with flow diagrams that graphically show the sequence of tests.

As a general remark, it must be noticed an effort to model the effects of many experimental parameters in the evaluation of the different typologies of losses.

Some Experimental Results

In our Laboratory of Electrical Engineering at the University of L’Aquila, we have been testing several induction motors whose rated power is up to 15 kW (400 V, 50 Hz, TEFC, squirrel-cage), both for research and industrial applications since 1994 (Fig. 3).

Today, our Laboratory is equipped with state-of-the-art instrumentation.

In detail, in this paper, some results about efficiency measurement according to the current version of the standards [5, 6] are presented.

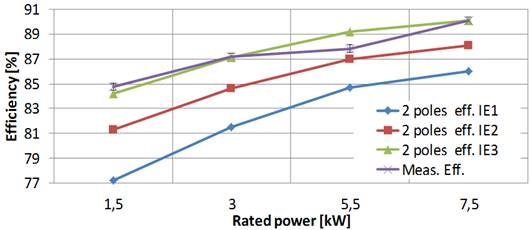

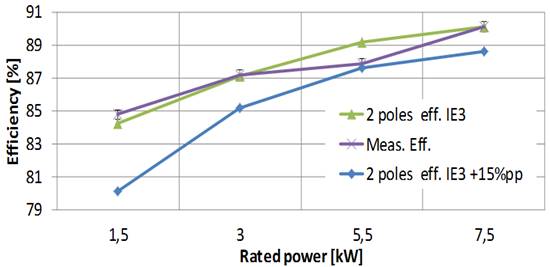

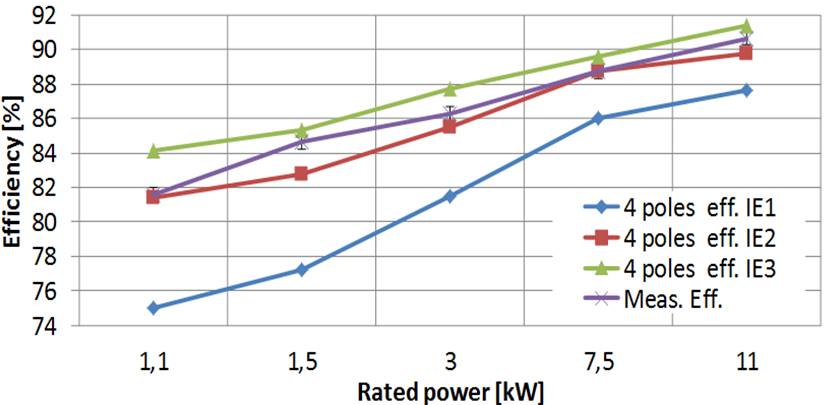

Fig. 4 shows the experimental testing results for IE3 – 2 poles induction motors; the accuracy achieved in efficiency measurement is ± 0,30 % by adopting high accuracy power analyzers and mechanical transducers.

We can observe that only the 5.5 kW motor is below the IE3 efficiency; however, because of the allowed 15% uncertainty in power losses measurement, the manufacturer could correctly classify it as IE3 as suggested by Fig. 5.

This issue is more evident in Fig.6 for the 4-poles induction motors we tested; all of them are characterized by measured efficiency lower than the IE3 curve, which we have measured with experimental uncertainty of +/-0,40%.

Nevertheless, although all of them are below the IE3 curve, they can be classified as IE3 because the manufacturer can take advantage of the allowed 15% uncertainty (Fig.7).

In other words, even if with a high accuracy measurement of efficiency, we demonstrate that an induction motor is below a rated IE efficiency value, the manufacturer could not be criticized because the EC Regulation N. 640/2009, Annex III allows him to perform the efficiency measurement with low accuracy.

Final Remarks and Conclusion

Finally, some remarks about legal issues can be raised in assigning an efficiency class for a measured efficiency.

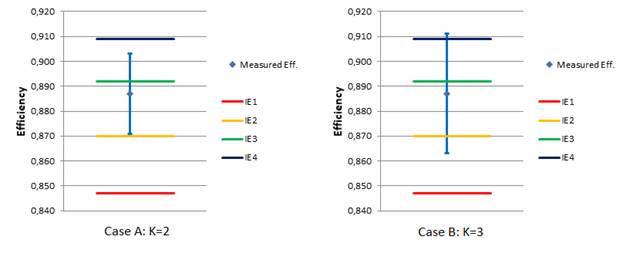

In Fig.8, what is the correct IE class, for a measured efficiency for the case A in which a coverage factor k=2 (95% confidence) is adopted according to the GUM [5]? The motor complies with IE2 requirements because all the data set is over IE2 level.

But I cannot exclude that it is IE3. If we extend the uncertainty, with k=3, (99% confidence), the data set covers 4 IE levels. So, which is the correct IE code for this motor?

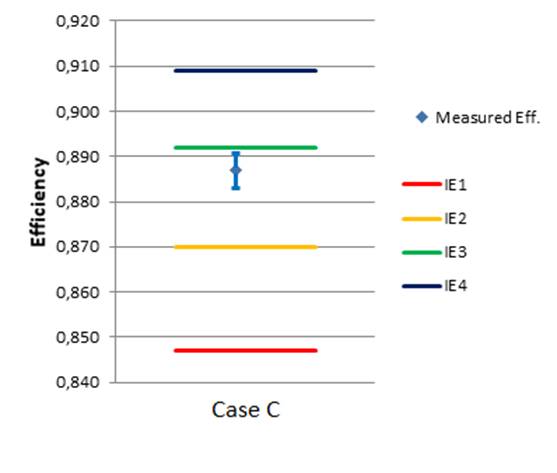

Maybe some additional suggestion of requirements in the international standards can be helpful, starting from the observation that the differences between two contiguous IE levels cannot be thinner than the measurement uncertainty; the desirable scenario is in Fig. 9.

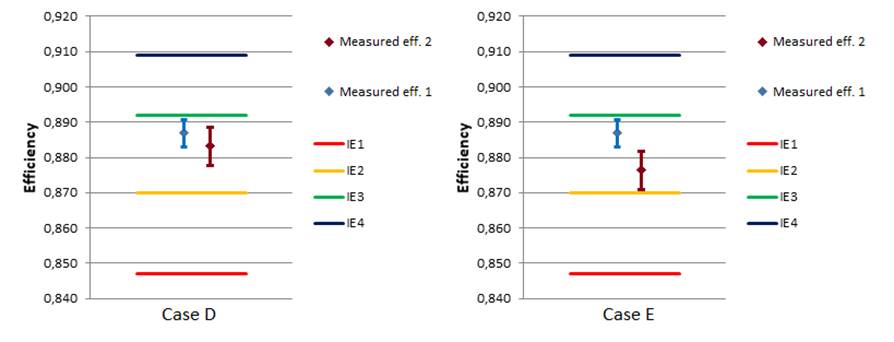

Finally, how are two different data set to be considered if they are different? It is a typical situation in the measurement field. In this case, we must check if they are superimposable.

In Fig. 10, case D shows two sets that are compatible because they are partially superimposable.

Case E in Fig. 10 depicts how the measurements are not compatible, even if they lead to the same IE results because the motor complies IE2 level.

Some references that can be of interest to operators involved in this complex scenario are listed as [8-11].

References

[1] COMMISSION REGULATION (EC) No 640/2009 of 22 July 2009 implementing Directive 2005/32/EC of the European Parliament and of the Council with regard to eco-design requirements for electric motors.[2] IEC 60034-30-1:2014 Rotating electrical machines – Part 30-1: Efficiency classes of line operated AC motors (IE code).

[3] ISO/IEC GUIDE 99:2007 International vocabulary of metrology — Basic and general concepts and associated terms (VIM).

[4] ISO/IEC 17025:2017 General requirements for the competence of testing and calibration laboratories.

[5] SO/IEC Guide 98-3:2008 (JCGM/WG1/100) Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995).

[6] IEC 60034-2-1:2014 Rotating electrical machines – Part 2-1: Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles).

[7] Power Analyzer Accuracy and Basic Uncertainty Calculator R511.xls, 2021, [online] Available: http://tmi.yokogawa.com/.

[8] Rajan, A., Kuang, Y.C., Ooi, M.P.-L., Demidenko, S.N. Measurement uncertainty evaluation: Could it help to improve engineering design? (2019) IEEE Instrumentation and Measurement Magazine, 22 (2), art. no. 8674631, pp. 27-32. DOI: 10.1109/MIM.2019.8674631.

[9] G. Bucci, F. Ciancetta, E. Fiorucci and A. Ometto, “Uncertainty Issues in Direct and Indirect Efficiency Determination for Three-Phase Induction Motors: Remarks About the IEC 60034-2-1 Standard,” in IEEE Transactions on Instrumentation and Measurement, vol. 65, no. 12, pp. 2701-2716, Dec. 2016. DOI: 10.1109/TIM.2016.2599459.

[10] Dubois, C., Leblond, L., Pou, J.-M., Ferrero, A. Covariance evaluation by means of uncertainty assessment (2016) IEEE Instrumentation and Measurement Magazine, 19 (6), art. no. 7777646, pp. 12-18. DOI: 10.1109/MIM.2016.7777646.

[11] Bucci, G., Ciancetta, F., Fiorucci, E., Mari, S., Segreto, M.A. The measurement of additional losses in induction motors: Discussion about the actually achievable uncertainty (2019) Energies, 13 (1), art. no. 78. DOI: 10.3390/en13010078.