Duxion Motors has successfully accomplished the ground test of its patented eJet motor: the motor prototype has had a positive outcome at both low and high speed. Rick Pilgrim, President and CEO of Duxion Motors declared: “The eJet motor is the first rim-driven jet propulsion motor in the world, able to match the existing jet motor thrust but without emissions. The eJet motor is new, scalable and can be configured to power a large base of airframes. We never doubted this day would come. Our confidence is rooted in the years of research, the innovation and quality of the design, and the depth of expertise and relentless passion within the Duxion team,” adds Mr. Pilgrim. “This is only the beginning.”

The world’s fleet of over 30,000 jet-powered aircraft account for 2.5% of global CO₂ emissions. The eJet motor replaces traditional, fossil fuel burning engines, enabling the transition to zero-emissions flight for jet aircraft. The eJet is also quieter than combustion jet engines, which will enhance passenger comfort and impactfully reduce noise pollution for the global community.

Test completed for the eJet by Duxion Motors

The Chinese BatteroTech lands in Turin for its industrial recovery

The headquarters of BatteroTech, Chinese company that develops solutions for the electric mobility and is part of the Chinese mining giant Tsingshan (56 billions of turnover and 60,000 employees) is in Turin, precisely at Solferino Square. The giant, which has all papers in order to be a new protagonist of the electric mobility also in the new continent, has then bet on Italy for its first headquarters in Europe.

«The target is developing a commercial network for our batteries and collaborating with companies like Stellantis, but we have chosen establishing in Turin, and not in Milan, because it is actually the automotive city and involves competitive induced activities», affirmed Benson Feng, vice president of the company.

Some data to outline the weight of this Asian reality? Tsingshan Group has just invested 233 million dollars in lithium mines in Chile and other 400 millions in Argentina to supply raw materials to car makers and to rank among the leaders in the battery market also in Europe. «We are supplier of all Chinese automotive companies, with the exception of Byd that manufactures everything in-house. Our intent is investing and manufacturing batteries for electric cars in Europe».

Mahle receives CLEPA innovator award for SCT electric motors

The Mahle SCT (Superior Continuous Torque) electric motors integrated oil cooling system concept for electric motors has been awarded the Top Innovator Award 2023 by the European Association of Automotive Suppliers (CLEPA).

The new integrated oil cooling system ensures that the traction motor can run at high power for an unlimited period of time.

With this technological leap, the performance of electric cars and commercial vehicles is greatly increased.

«This award is very special for us as it shows that we can set new technology benchmarks in e-mobility with our innovations» said Arnd Franz, Chairman of the Mahle Management Board.

With the SCT electric motor, Mahle currently has the longest-lasting electric motor in the range.

According to test results, it can consistently deliver between 93 and 100 percent of its peak power.

This is made possible by the innovative integrated oil cooling system, which not only makes the electric motor robust, but also allows waste heat to be used in the overall vehicle system.

The SCT electric motor is unrivaled in terms of small size, light weight and efficiency.

At the same time, the extremely compact design results in an advantage in the costs of materials and weight: a lighter motor requires less material during manufacture and increases the possible net load in commercial vehicles.

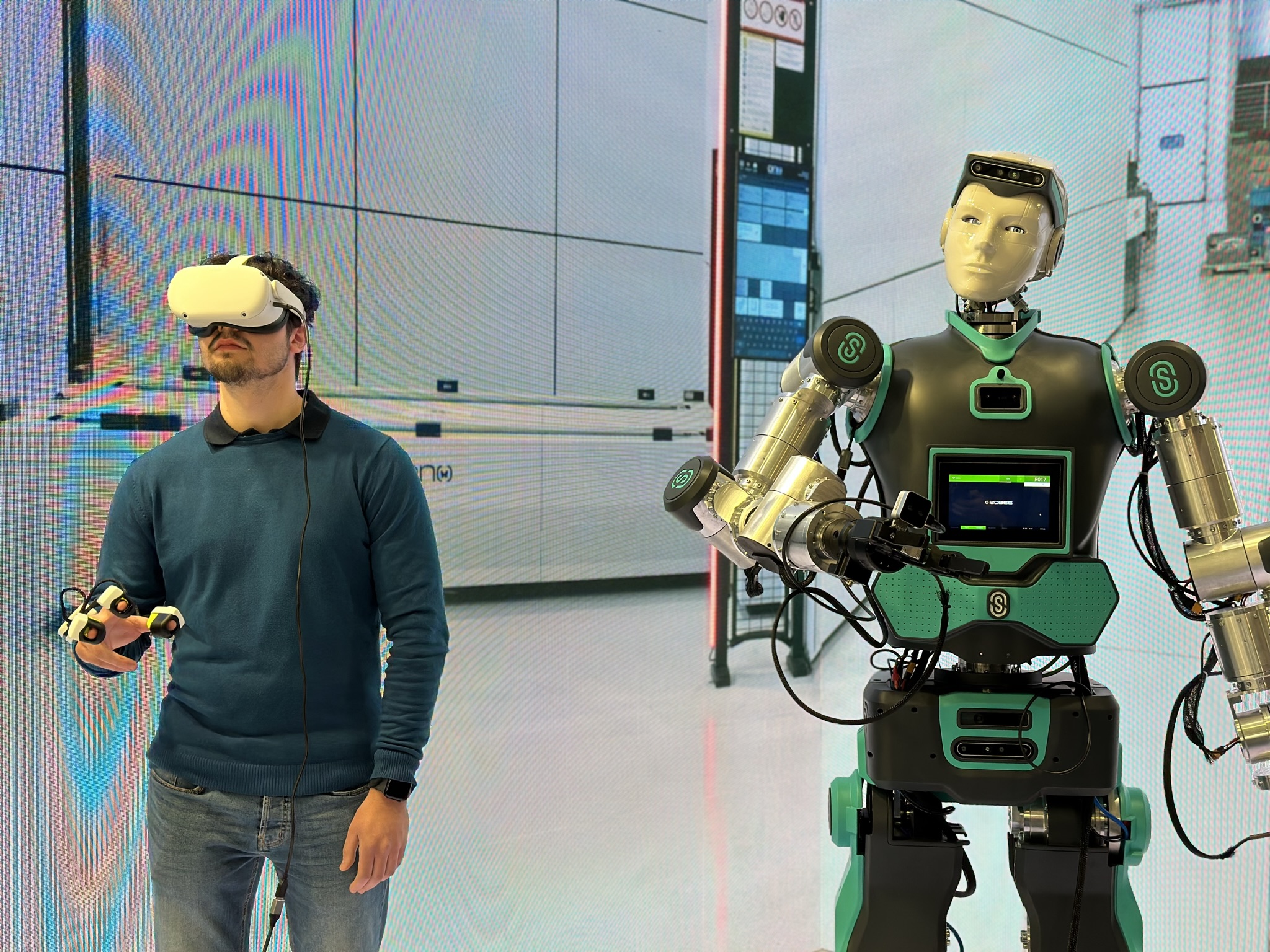

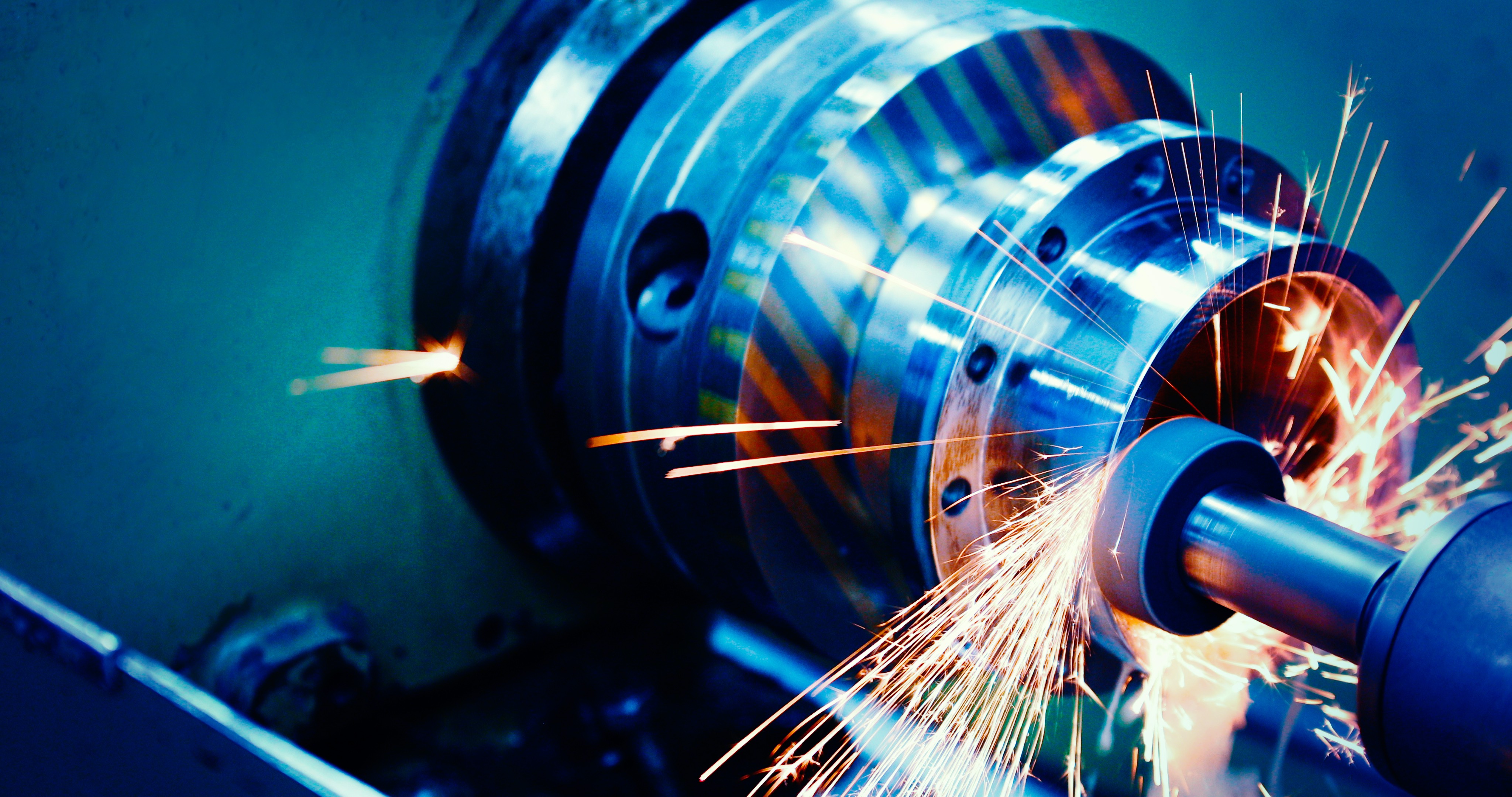

MECSPE 2024: towards human-centered Industry 5.0

From 6 to 8 March at BolognaFiere, Mecspe 2024 will offer a three-day full immersion in innovation, sustainability and training.

After the Bari event in November 2023, the manufacturing industry will once again take centre stage with MECSPE from 6 to 8 March 2024 in the halls of BolognaFiere.

A return after the success of the last Bologna edition that saw the participation of more than two thousand exhibiting companies and nearly 60 thousand visitors (+52 percent over 2022).

Added to this is an unprecedented level of satisfaction, with more than three-quarters of visitors satisfied with the networking opportunities and the chance to catch up on the latest technologies in manufacturing.

Over the years, this event has become increasingly international, given Italy’s role on the European and world scene and thanks to the presence at the fair of buyers from all countries of the world.

According to ISTAT (Italy’s National Institute for Statistics), our country, along with Germany, has a production system with a strong manufacturing vocation, and more than one-third of the added value produced by companies operating in industry and services comes from this sector.

Export plays a major role: except for micro-enterprises, more than 50 percent of small businesses are active in foreign markets, a figure that exceeds 90 percent for medium to large enterprises.

Germany, the United States, France and Spain, are confirmed as among our country’s main trading partners.

This is the backdrop for the 22nd edition of MECSPE, an event that will have an even more global outlook to guide Italian companies on their national and international growth path.

A three-day expo where entrepreneurs will have a direct and “immersive” experience with the world of manufacturing, thanks to an exhibition and demonstration route to address the pillars of modern industry: innovation, training, and sustainability.

A journey that will propel visitors and exhibitors toward an increasingly 5.0 and human-centered industry.

The Exhibition Heart of MECSPE 2024

The 2024 edition will have the new Heart Exhibition “Energy Transition & Sustainability in the Manufacturing Industry“ as its central focus, dedicated to issues that entrepreneurs are particularly sensitive to, especially at this historic moment.

An area where issues affecting mobility, the manufacturing industry, and the hydrogen supply chain will be explored in depth, with demonstration stations, panel discussions, keynote speeches, and moments of discussion.

Through best practices and successful case histories, technology and market experts will illustrate the challenges facing the industry in the run-up to 2035 (stop of thermal engine registrations), the impact that sustainable mobility has and will increasingly have on the supply chain, and the measures that can be taken.

In addition, many celebrated events that have made MECSPE a benchmark for the industry will return, such as the TMP Square, the Planning and Design Square, and the Startup Factory, initiatives where different players in the industry can get involved to present their projects or attend learning moments.

Throughout this journey, innovation and training will be the soul of many initiatives, confirming MECSPE’s role as a guide also for the new generations and for a new way of doing business, more suitable for young people and above all environment-friendly.

It is precisely the theme of sustainability that will be emphasized during the three days thanks to the Sustainability Goal Path (evolution of the EcoFriendly Path), an initiative designed to give visibility and reward exhibitors who have already embarked on a path of sustainability, in its three declinations—environmental, social and governance.

A direction, the sustainable one, in line with the values of Senaf, the company that organizes MECSPE and has been promoting specialized trade fairs, thematic trade shows, and congresses for more than 30 years.

In 2023, Senaf obtained the ISO 20121 certification to create and provide a sustainability management system for live events, evaluating and monitoring all the processes that are required for the holding of an event in compliance with social and economic sustainability parameters.

In addition, the collaboration with the main industry associations that have supported MECSPE in recent years continues, including Ascomut, Aidam, Confimi, Comet, Confapi, and Confartigianato, with their respective “Villages”, and CNA Produzione, helping organizers develop an innovative and sustainable business culture.

Facts and figures of MECSPE 2023

59,845 visitors operating in the trade sector (+52 percent compared with 2022), 92,000 sq m of exhibition space, 2,000 companies present, 2,034 sq m of the Heart Exhibition ‘Energy Transition and Mobility of the Future’, and 20 special initiatives.

Advanced Electric Machines: the key is the absence of rare earths

Increasing the production of an innovative electric rare earths-free motor is the main target of the financing in favour of Advanced Electric Machines (AEM) by the Advanced Propulsion Centre.

The SIMPLE (Scaled-up Innovative Motor Production for Lower Environmental impact) project by AEM will see the company manufacture a pilot line dedicated to the mass-production of its patented technology of motors for SSRD cars.

The key is the absence of rare earths, to the extent that AEM states that the widespread adoption of its motors, which can be manufactured with aluminium and steel only, has the potential of saving 133 million tons of CO2 equivalent, 300,000 tons of radioactive wastes and five million tons of wastes in landfills every year.

«While we are scaling the SSRD production to hundreds of thousands of units per year, we have to understand how optimizing manufacturing processes for large volumes, meanwhile complying with the cost and performance targets demanded by our customers» explained Andy Steven, Chief Technical Officer of Advanced Electric Machines.

James Widmer, CEO and co-founder of Advanced Electric Machines, added: «This financing has the potential to transform the supply chain in the United Kingdom, laying the bases for a significant increase of the sustainable motor manufacturing. The results of this project will contribute to create qualified workplaces and to favour further innovations in the United Kingdom».

Schaeffler and H2 Green Steel intensified their collaboration

Schaeffler continues decarbonization journey and plans to achieve complete climate neutrality by 2024 and aims to achieve climate neutrality in its production processes by 2030.

A goal for which the choice of materials, particularly steel, is key: every day the company processes as much steel as the Eiffel Tower, or more than 7,000 tons.

That is why Schaeffler has increased its stake in H2 Green Steel, the steel supplier, by investing another 65 million euros, a significant increase that brings its total stake to 100 million euros.

This is the highest share Schaeffler has ever invested in a minority stake in another company.

The advantage of the green steel purchased from H2 Green Steel is that it has up to 95 percent less embodied CO₂ emissions (Scope 3 upstream) than conventional steel produced via the blast furnace route.

Andreas Schick, Chief Operating Officer of Schaeffler AG, explained: «For Schaeffler, steel is the decisive lever to decarbonize our supply chain. The partnership with H2 Green Steel takes us a long way toward our goal of climate neutrality».

HEXA, the first eVTOL aircraft to have flown in Japan

LIFT Aircraft has recently completed the first-ever piloted eVTOL demonstration flights in Japan with their aircraft, HEXA.

The flights were conducted in partnership with Marubeni Corporation, with whom the Austin, Texas based company is partnering to develop and advance the eVTOL market in Japan, and with participation from GMO Internet Group.

With Osaka castle in the background, after about one hour of training and introduction to the aircraft, Masatoshi Kumagai from GMO Internet Group piloted HEXA, successfully accomplishing three flight schemes.

Flights were conducted for audiences that included the Japan Civil Aviation Bureau (JCAB), the aviation authority of Japan.

Although HEXA complies with FAA Part 103 and can be flown in the United States today without aircraft type certification or pilot license, Japan does not yet have equivalent regulation.

JCAB carefully reviewed the safety of the aircraft, the extensiveness and maturity of the test program, the flight envelope, and ultimately gave permission for the demonstrations to proceed.

Matt Chasen, founder and CEO of LIFT Aircraft said: «JCAB was thorough in their review of our safety standards and our aircraft, and gave us the green light to fly. It’s an honor that our aircraft was selected to be the first eVTOL ever piloted in Japan».

LIFT has formally concluded Phase 1 flight test and beginner flight envelope development with the U.S. Air Force and has launched Alpha Flights, allowing people outside of their Flight Operations and Test teams to fly.

eCrate, a new concept design for a plug-and-play modular eDrive unit

GKN Automotive has unveiled eCrate, a new plug-and-play eDrive concept designed to meet the growing demand among niche electric vehicle players and EV conversion companies for modular eDrive unit.

The new eCrate concept utilises GKN Automotive’s 20 years of eDrive experience to create a cost-effective modular electric drive system with optimal efficiency and performance and market-proven technology in an off-the-shelf format.

With a choice of three systems, the first of which could be available as early as 2025, prospective customers can select the best solution for their required application from a 113 kW 2-in-1 combination system (motor and transmission) or a fully integrated 3-in-1 system comprising an electric machine, transmission and inverter, in a choice of 113 kW or 185kW output.

Targeted toward the growing number of niche and low volume electric vehicle players, as well as the retro-conversion market, the concept aims to test market appetite for a new approach to eDrive sales.

Suitable for various purposes, including small to large cars and light commercial vehicles in series production, the concept has the potential to help accelerate the transition to full electrification by empowering start-ups and established low volume players.

Dirk Kesselgruber, Chief Technology Officer at GKN Automotive, comments: «We have spent the last 20 years producing leading eDrive technologies for global vehicle manufacturers, enabling them to drive the electric revolution. Based closely on our existing technology, our new eCrate concept will bring this technology to even more customers looking for high-quality and cost-effective electric drive units in a plug-and-play format. By introducing new innovative and sustainable solutions, we are helping to drive a cleaner, more sustainable world».

It is a combined motor and transmission system: this powerful system boasts an impressive 113 kW output.

Next, 2-in-1 System: GKN is taking it up a notch with this system, offering both 113 kW and 185 kW output options, followed by 3-in-1 System: hold on tight because this system packs a punch with not one, not two, but three output options: 113 kW or 185 kW.

With over 20 years of experience in producing electric motor technology for global vehicle manufacturers, they’ve got the expertise to back it up and to ensure their systems, GKN has put them to the test in vehicles based on the Tesla Model 3 and Fiat Ducato.

The market of axial flux motor will increase by 29.80% until 2027

According to an exhaustive analysis carried out by TechSci Research in its report entitled “Automotive Axial Flux Motor Market – Global Industry Size, Share, Trends, Competition, Opportunity, and Forecast, 2017-2027F“, the global market of axial flux motors for vehicles scored an assessment of 108 million dollars in 2021.

Moreover, it will be concerned by a notable compound annual growth rate (CAGR) by 29.80% until 2027.

The growing importance of axial flux motor in the market derives from their intrinsic advantages, including the higher energy efficiency, compact sizes and sound torque specifications, which make them rank as potential replacements of conventional radial motors.

Thanks to their small sizes and the high power density, these motors find an ideal use in a multitude of commercial applications, such as industrial robots, pumps, compressors, electric vehicles and drones.

They offer, in particular, a substantial advantage in the torque production, surpassing radial motors by 30-40% and maintaining a higher power density.

The yokeless version of axial flux motors, in particular, is intended for conquering a growing share of the constantly evolving market of electric motors.

MECSPE Bari: the new edition of Focus Mediterraneo

The new edition of MECSPE Focus Mediterraneo reconfirms Bari’s role as a driver of innovation for Southern and Central Italy.

One of the most important meetings for the manufacturing industry in Southern and Central Italy is back: starting Nov. 23 and running through Nov. 25, Bari’s Nuova Fiera del Levante will host MECSPE, the leading trade fair on the manufacturing industry, to take stock of an increasingly strategic sector for the country’s economic fabric.

All this thanks to the 20,000 sq m of exhibition space, 13 thematic salons, 350 companies present, more than 100 conferences and workshops, special initiatives, exhibition areas, and the support of institutions and associations including the Apulia Region, Bari Municipality, Confindustria Bari BAT, Confimi Meccanica, CNA Produzione, Distretto La Nuova Energia, Distretto Produttivo Informatica, AIDAM, ASCOMUT, and Sprintx

The new edition of MECSPE Focus Mediterraneo thus reconfirms Bari‘s role as a driver of innovation for Southern and Central Italy; three days in which ample space will be given to innovation processes and virtuous practices implemented in the sector, with entrepreneurs having the opportunity to participate in networking and training events and activities, discover the excellence of the entire supply chain for a 5.0 and innovative digital factory, focusing on the key themes of innovation, sustainability, and training.

Where do Italian companies stand on these processes? The path to digital transformation has undoubtedly begun, and entrepreneurs have realized the importance of not only adopting new technologies in the company but also creating the conditions for a deep internal cultural transformation geared toward innovation.

A culture that is also reflected on the sustainability front, and to which entrepreneurs are beginning to devote more and more energy and investment—but we are in our infancy.

Exhibition Core

The central area of the fair, the Exhibition Core “Energy Transition and Industry 4.0: Sustainability in Manufacturing“, will take stock of issues of close relevance and interest to innovative entrepreneurs, and all three days will see market and technology experts discuss the challenges of the future and the industry’s impact on the environment and its communities.

The event will provide an opportunity to anticipate market trends and share innovative content through meetings and practical cases involving partners, event exhibitors, and technical sponsors.

These themes will also expand to the Innovation Plaza for Energy Transition, where topics such as research and development of innovative materials and technologies for high-tech industries will be explored.

Bari is an ideal setting to make a significant contribution to these issues given the presence in the region of a cluster dedicated to aeronautics, high-tech industries, and research centers such as Bari Polytechnic and CETMA.

New features of this edition include the StartUp Factory, which will land in Bari for the first time, following the success of the Bologna edition, offering high-tech B2B startups networking and presentation opportunities to a wide audience from the manufacturing industry. There is no shortage of attention to sustainability issues, which are increasingly integrated into corporate strategies, evidence of a rapidly growing awareness in the area. From this awareness was born the Sustainability Goal Path, an evolution of the EcoFriendly Path, an initiative that aims to give visibility and recognize exhibitors who have already embarked on a path of sustainability, in its three declinations, environmental, social, and governance.

A direction, the sustainable one, in line with the values of Senaf, the company that organizes MECSPE and has been promoting specialized trade fairs, thematic trade shows, and congresses for more than 30 years.

In 2023, Senaf obtained the ISO 20121 certification to create and provide a sustainability management system for live events, evaluating and monitoring all the processes that are required for the holding of an event in compliance with social and economic sustainability parameters.

Training 4.0

Rounding out the schedule of appointments will be the third soul of MECSPE Focus Mediterraneo, training, which will play a central role in the context of Training Square 4.0, thanks to the collaboration between MECSPE and Fondazione ITS A. Cuccovillo, a meeting space that offers new opportunities to young people and promotes the development of the territory.

Now more than ever, schools and companies must work closely together to engage new talent and put them in direct relation with the world of the manufacturing industry, providing an opportunity to understand the importance of training designed to acquire innovative technical skills.

A Speech Area and a Demonstration Area will host the different partners to better engage students.

The MECSPE Young & Career area is also being developed to facilitate contact between students who are close to entering the world of work and companies that are present and always looking for trained young people to join their workforce.

Students will be involved through playful, hands-on activities that will challenge them by bringing them closer to manufacturing realities.

To consolidate the relationship between production realities in the plastics sector, TMP will be present with some of its associates in TMP Square.

As was the case at the Bologna edition of the fair last March, some members of the association will also be present at MECSPE Focus Mediterraneo to promote an increasingly close and broader collaboration among companies from Northern, Central and Southern Italy to protect the competitiveness of our country.

Space is also given to internationality, a crucial element for growth and at the same time a strength of Italian industry.

The new edition of MECSPE Focus Mediterraneo aims to act as a driving force to foster the internationalization of the area’s industries: exhibitors at the fair will have the opportunity to meet with buyer delegations from European and non-European countries during the days of the event through a program of matching and one-to-one business meetings.

MECSPE thus reconfirms its role as a showcase for major industrial districts and Made in Italy manufacturing excellence.

Within the event, there will also be no shortage of historical events such as the AIDAM Village, the Italian Association of Mechanical Automation, and the ASCOMUT Village, the Italian Association of Machine Technology and Tools, which represents import and distribution companies and branches of foreign houses.

«We are thrilled to return to Bari with the new edition of MECSPE bringing a program so rich in content and so relevant to our industry» says Maruska Sabato, MECSPE project manager. «The manufacturing industry is fundamental to the Italian economy, and we must continue to work to foster its development through innovation and new enabling technologies. It is necessary to ensure the appropriate training of resources to respond to this evolution, while always giving a central role to sustainability, which guarantees the health of the companies in the sector and all those involved in it. All this will find ample space for discussion and debate at MECSPE, which stands as a reference point and promoter of excellence in the manufacturing sector.»

The figures of MECSPE BARI 2023

20,000 sq m of exhibition area, 350 companies attending, more than 100 conferences and workshops, 8 special initiatives, 3 pavilions, and the Core Exhibition “Energy Transition and Industry 4.0: Sustainability in the Manufacturing Industry.” 16,243 professional visitors participated in the last edition (2019).