It is electric the motor that has shared in the building of Morgan Stanley’s Chelsea Flower Show Garden, designed by Chris Beardshaw, park situated at the core of London, winner of the Best Show Garden. ECR25 Electric vehicle by Volvo CE, electric compact excavator, shared in fact in the construction of this futuristic experiment of urban gardening, able to host about 157,000 visitors.

The machine was used to excavate the ground and to position the foundations for the main structure and the trench for tree pits and to house the central fountain. The recharge was carried out at the end of each working day, at night, using a standard domestic outlet. When fast recharges during the day were asked, the operator used the recharger on board.

«Zero emissions and the lower noise level are an absolute turning point – affirms Ahcène Nedjimi, Electromobility Specialist by Volvo CE. – Now the challenge is understanding the best way to optimize them at best for each application. The question is no longer when, or if, the shift to electromobility will occur but how quickly it will happen. We are really at the point of no return. We must reduce emissions, pollute less and build the world where we want to live».

Compact electric excavator for the world renowed garden

Cybersecurity. Automotive market requests a certified management

With the introduction of the new European security guideline according to ECE level (UNECE WP29; valid in the EU and partly in Asia), in future vehicle manufacturers will be required to verify the cybersecurity of their vehicle systems before their products can obtain type approval.

From now on, manufacturers must prove every three years that they have applied a certified cybersecurity management system which covers all stages ranging from vehicle engineering through to documentation. Using the cybersecurity management system, manufacturers must test the cybersecurity of all vehicle types, identify and document potential threats, address security-critical problems and suggest solutions, and finally demonstrably verify that these problems have been solved.

In this context, comes the launch of an Austrian product, ThreatGet, jointly developed by the AIT Austrian Instituteof Technology and Sparx Services CE. It helps developers identify threats at an early stage, allowing them to quickly assess the associated.

This cybersecurity verification requires a modern tool which, for the first time, allows manufacturers to test their systems for ECE compliance.

Peter Lieber, the founder of Sparx Services CE: «We have been working with AIT on this solution for two years and are proud that we can launch it on the market so quickly. ThreatGet offers IT system designers effective support for security procedures designed to prevent potential cyberattacks, or threats».

Set against the background of a strongly growing security engineering industry, ThreatGet is targeted at vehicle manufacturers, as well as all companies involved in analysing vehicle architectures and systems in order to issue certification.

The world first driverless parking officially approved for everyday use

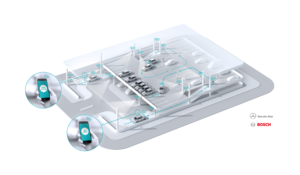

Bosch and Daimler have reached a milestone on the way to automated driving: the two companies have obtained approval from the relevant authorities in Baden-Württemberg for their automated parking system in the Mercedes-Benz Museum parking garage in Stuttgart.

The two companies started developing fully automated driverless parking in 2015, and in the summer of 2017, their pilot solution in the Mercedes-Benz Museum parking garage in Stuttgart reached an important result: automated valet parking in real conditions, with and without drivers at the wheel, was presented to the public for the first time. This premiere was followed by an intensive testing and start-up phase. Starting in 2018, museum visitors could use the parking service live, accompanied by trained safety personnel, and share their experience. One aspect of the pilot project involved testing lighting concepts on the vehicles. Turquoise lighting indicates that a vehicle is in automated driving mode and informs passers-by and other road users that the vehicle is driving itself. The insights from these tests are reflected in the recently issued SAE standard 3134.

Obtaining final approval from the the Baden-Württemberg authorities is a further major milestone for Bosch and Daimler and sets a precedent for obtaining approval in the future for the parking service in parking garages around the world.

Obtaining final approval from the the Baden-Württemberg authorities is a further major milestone for Bosch and Daimler and sets a precedent for obtaining approval in the future for the parking service in parking garages around the world.

Interested parties will be able to experience the innovative valet parking service live in daily operation in the Mercedes-Benz Museum parking garage without additional supervision from a safety driver.

The automated valet parking service is accessed via a smartphone app and requires no safety driver. This makes it the world’s first fully automated driverless SAE Level 4 parking function to be officially approved for everyday use.

Safety & technology

From the very beginning, Bosch and Daimler’s top priority for the driverless parking service was safety. Since there is as yet no official approval process for automated driving functions that do not require a driver, the local authorities – the Stuttgart regional administrative authority and the state of Baden-Württemberg’s transportation ministry – oversaw the project along with experts from the German technical inspection service TÜV Rheinland from the outset. Their aim was to assess the operating safety of the automotive and parking-garage technology.

The result is a comprehensive safety concept with appropriate testing and approval criteria that can be applied beyond this pilot project. In the concept, the developers defined how the driverless vehicle detects pedestrians and other cars in its path and reliably comes to a halt when it encounters an obstacle. They also set up secure communications between all system components and took steps to ensure the reliable activation of the parking maneuver.

The result is a comprehensive safety concept with appropriate testing and approval criteria that can be applied beyond this pilot project. In the concept, the developers defined how the driverless vehicle detects pedestrians and other cars in its path and reliably comes to a halt when it encounters an obstacle. They also set up secure communications between all system components and took steps to ensure the reliable activation of the parking maneuver.

The technology behind driverless parking

Drive in to the parking garage, get out, and send the car to a parking space just by tapping on a smartphone screen – automated valet parking has no need for a driver. Once the driver has left the parking garage to go about their business, the car drives itself to an assigned space and parks. Later, the car returns to the drop-off point in exactly the same way. This process relies on the interplay between the intelligent parking garage infrastructure supplied by Bosch and Mercedes-Benz automotive technology. Bosch sensors in the parking garage monitor the driving corridor and its surroundings and provide the information needed to guide the vehicle. The technology in the car converts the commands from the infrastructure into driving maneuvers. This way, cars can even drive themselves up and down ramps to move between stories in the parking garage. If the infrastructure sensors detect an obstacle, the vehicle stops immediately.

Vehicle to grid. Maximize self-consumption in Italy

The technology that allows cars to store and return energy for the net stabilization is called Vehicle to Grid (V2G). The first experimentation in Italy is in starting phase by Enel X, Nissan and RSE.

The project provides for the use of two bi-directional recharge infrastructures by Enel X, installed in the experimental micro-net by RSE, which through a special control platform allow using Nissan Leaf for the net stabilization.

The project target is testing the functions of V2G according to the habits of private users and of those who use corporate fleet vehicles. During recharge times, batteries will be used as energy accumulation systems connected to the net, able to assure advantages for the electric system and car owners.

In particular, V2G technology will allow maximising the self-consumption of renewable energy by domestic plants, optimizing the flows of energy produced and consumed locally and granting the continuity of the energy supply in case of interruptions.

The possibility of exploiting batteries for more purposes through Vehicle to Grid on one hand will permit to make use, without additional costs, of a domestic or business accumulation system and, on the other hand, to give an important contribution to the stability and the efficiency of the electric system; an instrument able to further favour the diffusion of electric vehicles in Italy.

Elemaster Group, another goal for the strategic global development

Elemaster announces to have finalized the acquisition of 100% of GDM Electronic’s shares. This investment represents another strategic step for the realization of Elemaster’s globalization plan, according to the business plan “Vision 2020”: now the Elemaster Group’s plants are located in Italy, Germany, Belgium, Romania, USA, China, India and Tunisia.

Mr. Gabriele Cogliati, Elemaster’s President & CEO states: “I’m really proud to evidence that, in the same year when Elemaster celebrates its 40th anniversary since its constitution, we have achieved another important goal for the strategic global development of Elemaster Group. Our Company is strengthening its presence in the world and this year we will complete three additional projects: the inauguration in May 2018 of a new and larger facility in China, the opening in July 2018 of a new and state of the art plant in the USA (Duluth, Georgia) and the expansion of our German subsidiary, CAD UL GmbH, where we would like to create an European center for electronic engineering and fast prototyping”.

Mrs. Valentina Cogliati, Elemaster’s Managing Director, concludes : “This investment opens our Group to new opportunities and enables us to be identified as the ideal partner for the strategic growth and competitiveness of our Customers: we will get closer to our Clients in the Centre of Europe, achieving also new opportunities in northern Europe”.

Innovative electric water taxi

A futuristic, zero-emission new design of water taxi, called SeaBubbles, was demonstrated on Lake Geneva in Switzerland. The vehicle represents a milestone in the development of new forms of transportation that do not impact the environment or place any burden on urban infrastructure. The water taxi will soon be equipped with the ABB Ability™ Marine Advisory System – Octopus, a software solution that helps vessel operators gather and analyze all relevant data to optimize water travel.

The development of the demonstration craft was supported by the Geneva cantonal authorities and the Department of Energy, Transport and Agriculture (Deta), represented by State Councilors Luc Barthassat and Pierre Maudet, drawing on technology from ABB. Further trials will continue in the months ahead.

The ABB Ability™ Marine Advisory System – Octopus will be deployed by the pilot project. The Octopus system will enable ABB to provide real-time data to the SeaBubbles control center, covering virtually every aspect of the vessels’ operating status.

Unusual self-parking amenities

Combining the ultimate in traditional hospitality with Nissan’s autonomous driving technology, one Japanese inn is treating guests to some unusual amenities: self-parking slippers, tables and floor cushions.

The ProPILOT Park Ryokan looks like any other traditional Japanese inn, or ryokan. Slippers are neatly lined up at the foyer, where guests remove their shoes.

Tatami rooms are furnished with low tables and floor cushions for sitting.

What sets this ryokan apart is that the slippers, tables and cushions are rigged with a special version of Nissan’s ProPILOT Park autonomous parking technology. When not in use, they automatically return to their designated spots at the push of a button.

First introduced in the all-new Nissan Leaf in Japan in October 2017, ProPILOT Park detects surrounding objects and lets drivers automatically park the vehicle in a selected parking space by pressing a button. The same technology is being used in the amenities at the ProPILOT Park Ryokan during a demonstration to entertain guests and reduce staff workload.

Autonomous parking technology

ProPILOT Park is a fully fledged system that helps drivers park by automatically controlling acceleration, brakes, handling, shift changing and parking brakes to guide the car into a parking spot.

By combining advanced image processing technology using four high-resolution cameras and information from 12 ultrasonic sensors around the car, ProPILOT Park guides the car into a space safely and accurately.

All steering, braking and throttle inputs for various parking maneuvers, such as parallel parking, are automated. The system can automatically identify a parking space around the car so that the driver doesn’t need to set a target parking position. Requiring only three easy steps for activation, this technology liberates drivers from one of the most tedious, and at times the most challenging, tasks of driving.

Giuseppe Nardella. 1938 – 2018

Suddenly, on January 6th, Giuseppe Nardella, chairman of the publishing group Tecniche Nuove, passed away. He founded the group in 1964 with the precise aim of spreading professional information, starting from mechanics and gradually developing the activities and editorial products at all the fields of industry.

Giuseppe Nardella builded a large company with the force and concreteness of ideas and he lived to the last day with the enthusiasm of the beginning. Tecniche Nuove is, at the moment, the largest publishing group in Italy covering widely professional and scientific editorial fields.

Employees and collaborators of the group – Tecniche Nuove, New Business Media, Senaf, Accademia Tecniche Nuove, Grafica Quadrifoglio, Ariesdue, Ticino Edizioni, Centro Marketing, Jonio Comunicazione, Brazil Media Communications – along with the family, tighten around Ivo Alfonso Nardella who has been leading the company with his father in the last years and will continue his work.

“I am convinced that in every company there is an invisible soul, a sort of common thread, which can be interpreted as harmony in the relationships between the Management and the people who work around it; if this harmony and soul develop together with the company, success is assured “.

Many applications for the new K1W water cooled motor

The new K1W series of water-cooled motors has been recently launched by WEG, a global manufacturer of motor and drive technology.

The newly developed K1W motors are available up to energy efficiency class IE3 with rated power up to 700 kW and compact dimensions.

They are suitable for a broad spectrum of applications, including mixers, extruders, injection moulding machines, printing presses, paper machines and wire drawing machines. The new series of motors was developed by WEG’s German subsidiary Antriebstechnik KATT Hessen, commonly known as AKH.

“The K1W series is a completely new line of water-cooled motors which are cost effective and meet the needs of a large number of applications thanks to numerous options. Among other things, they are a good choice when a lot of power is needed in a small space and the lowest possible noise level is desired”, says Uwe Guthardt, Managing Director of AKH. “The K1W series is ideal in situations where an external fan is not possible due to a high dust burden in the air or the motor heat cannot be dissipated directly to the ambient, for example in an operating environment that is already at an elevated temperature.”

The new series of motors is built to the specifications of vibration level A, protection class IP55 and insulation class F as standard. The shaft height of the available motors is between 200 and 355 mm. The motor casing and bearing shells of the standard version are made from steel.

The electrical options include optimisation for variable speed drive operation as well as special voltages and frequencies. The mechanical options of the K1W motors include water-cooled shafts, electrically isolated bearings, automatic lubrication, and foot or flange mounting. Special bearings for high axial or radial loads, special shaft materials, and special surface treatment and a variety of paint grades are also possible. Drive components such as holding brakes, back stops, shock absorbers and various encoders are additionally available.