Experimenting Big Data technologies and super-calculation for enterprise, creating models that can simulate, through Digital Twins, manufacturing or management processes of infrastructures, permitting preventive maintenance, process optimization and production increase. That is the target of the IoTwins Project, funded in the ambit of Horizon 2020 (European Framework Programme for Research and Innovation) and shared by 23 partners coming from 8 European Countries.

It is a synergistic action that has involved, besides the head company Bonfiglioli (top player that on a world scale designs, manufactures and distributes a complete range of gearmotors, electric motors, planetary gearmotors and inverters), also the University of Bologna, which is guiding the scientific coordination, the National Institute of Nuclear Physics and Cineca, which stand out for their role in calculation infrastructures, Emilia-Romagna Region with Art-ER (the regional company that supports innovation, attractiveness and internationalization of the territorial system, for the development and the diffusion of the project’s results on a regional, national and European scale).

“The Innovation 4.0 Award” has acknowledged the competence of Bonfiglioli due to its IoTwins project, started in 2019, which has faced crucial themes like Big Data, Artificial Intelligence and the Internet of Things applied to manufacturing and infrastructures.

The Industrial Scientific Committee of A&T has chosen eight finalists among the 51 selected admitted projects.

The two winner companies, in an excellent level ex aequo, were Bonfiglioli Riduttori and Italian Rollwasch. On an equal footing, then, the IoTwins project by Bonfiglioli, with Big Data that become a modelling and forecast tool accessible to SME, too, and VibroBLAST, a patent for a revolutionary vibro-blasting technology.

In the picture: Fausto Carboni, CEO Business Bonfiglioli

The IoTwins project, here the prize won by Bonfiglioli

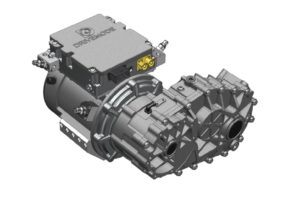

Double four-wheel drive e-motor with 9.6 kW of power

«Over 44,000 pre-orders in 48 hours for Ford F-150 Lightning electric pickup». It was publicly affirmed by Jim Farley, the CEO of Ford, which strongly focuses on this electric variant of a model that has literally depopulated in America in its standard version.

News that clearly witness the direction of the automotive market that in USA, but also in the rest of the Western world (and partly also Eastern), looks with ever-rising interest at the electrified versions of endothermic warhorses.

Ford has transplanted the electric powertrain on a frame Series F, redesigning it from scratch to house the two lithium-ion batteries in a high-strength steel structure and an aluminium bodywork to recover weight.

The e-pickup F-150 Lightning, available since the spring 2022, will be able to deliver 571 horsepower in the version with the more capacious battery and 432 CV for the one with standard battery, with a higher drive torque of 1,050 Nm and acceleration from 0 to 60 mph (97 km/h) in about 4.5 seconds.

The power supply is enabled by a double four-wheel drive motor, which with 9.6 kW of power supplies energy also to the house when necessary, for instance during a blackout.

Therefore, it is a real small “power plant”, which anyway aims at a large diffusion thanks to a low price.

In fact, since the beginning Ford has decided offering an electrified model able to pursue the utmost diffusion, proposing it at a price under 40,000 dollars and 4 variants.

“Bigger” than a smartphone

The startup EVR Motors, based in Israel has unveiled its new electric motor based on patented typology, TSRF (Trapezoidal Stator Radial Flux). The innovation is already ready for production and the company claims to have tested the first prototypes of the motor, whose size is less than half and 10% lighter than existing RFPM (Radial Flux Permanent Magnet) motors with similar power.

“Our small, lightweight motors – Opher Doron, CEO of EVR Motors – will provide vehicle manufacturers with improved performance while increasing installation flexibility and reducing costs.”

According to the company, this new TSRF motor typology will produce a higher amount of power and more density, besides reducing production costs.

Each TSRF solution can be tailored to the specific needs of the vehicle, including Battery Electric Vehicles (BEVs) to two-wheelers. Its technology supports voltage running from 48V to 800V.

Electric Motors Talks: great ideas also for aerospace applications

Last April 28th, in the second meeting with Electric Motors Talks, joint initiative of University of L’Aquila and of Coiltech to promote the exchange of know-how between specialists of Coil Winding and related ambits, Electric Motors for Aerospace applications played a protagonist role.

Experts from the academic and industrial world outlined in their speeches the state-of-the-art in the segment of electric motors in the specific world of aerospace applications.

The webinar will be chaired by Marco Villani, professor of Electric Machines Design and Electric Systems for Mobility at University of L’Aquila and technical director of Electric Motor Engineering review.

Prof. Marco Villani started with the statement that modern aircrafts are becoming more and more electric and then aerospace manufacturers’ focus on electric motors is growing. «The need of turning more massively to all related components also for aircrafts, at a sustainable cost, leads industries and universities to work to find increasingly innovative solutions, most of all in the electromechanical actuator ambit».

Moreno D’Andrea highlighted Electromechanical linear actuators with integrated electric motor for aerospace applications, as representative of Umbra Group company, which shares its technological know-how with customers, including software and electronics, to design, prototype, qualify and produce the best high-performance aerospace electromechanical linear actuators for critical applications. The integrated process is the result of ongoing investments in research and the deep commitment of a multidisciplinary team of technicians and engineers to developing customized solutions at competitive prices with short lead times.

During the event, the speaker D’Andrea presented electromechanical actuator components and actuator configurations, related applications, the electric motor design and the aileron surface.

Cooling of Electric Motors 26/05/2021 10.30-12.00

Magnetic Materials 09/06/2021 10.30-12.00

Manufacturing of Electric Motors for the Automotive Industry 23/06/2021 10.30-12.00

Insulating Materials 07/07/2021 10.30-12.00

SciMo, Science for Motion, was founded by a group of Ph.D. students from Karlsruhe Institute of Technology to offer electric motors with a power density far beyond the state-of-the-art. Furthermore, SciMo will offer services around electric motors like the electromagnetic design, mechanical calculations, CAD constructions as well as the manufacturing of prototype motors. The unique performance characteristics of motors are reached via our key technologies of copper fill factors above 70% using distributed windings and innovative cooling concepts, such as indirect cooling of the copper windings. No expensive materials used. SciMo High Performace Electric Motors have been built and used since 2013-year; a peak power density of more than 20 kW/kg and a continuous power density of 10 kW/kg have been reached. «There are 3 kinds of motors for aerospace applications. At first, Direct Drive for Horizontal propulsion; it is competitive without gearbox, the prop speed is 1000-3000 rpm, the power is higher than 1MW and torque level is 5-10 kNm. Besides, there is eVTOL, vertical/horizontal Propulsion, up to 200 rpm, a power of 5-100kW, a torque level of 50-100Nm: this solution for low power and high torque gearbox solutions offers best power to weight. Finally, there is High speed energy generator (direct coupling to gas turbine) with shaft speed of 35-70 krpm, power of 100 – 500kW, a torque level under 100Nm».

The Italian academic witness was by Giuseppe Fabri, researcher at University of L’Aquila who talked about high-reliability electric motor drive for helicopters tail rotor through research activities on designing, prototyping and testing of innovative electrical machines and drives for some applications like aerospace, automotive, domestic appliances, automation, electrical actuation and digital process control.

New business opportunities are connected with a new component electrification in aircraft and HC, new eVTOL vehicles for local transportation and electrical propulsion demonstrators. However, as great are the challenges and the opportunities for the coil-winding industry versus electric motors with extreme power density and high reliability and the enhancement of materials and manufacturing technologies.

Another University contribution came from England, via Prof. Christopher Gerada, from the University of Nottingham, who explained in detail the research project about electrical machines and winding technologies for aircraft applications.

The drive towards aircraft electrification is highly dependent on the performance and reliability of electrical machine drive systems. A review of the advancements of electrical machine constituent materials which are being applied in the aerospace sector is outlined followed by key advancements in electrical machine technologies. Case studies demonstrating advances in electrical machine technology will then be presented highlighting key performance indices achieved.

(by Lara Morandotti)

Fully electric tractor for Agriculture 4.0

Electric motors committed to the green transformation of agriculture? Last December, the American company Monarch revealed in pioneering manner its electric, smart and autonomous guide tractor.

It is Monarch Tractor, a vehicle featuring the typical shape and size of the compact tractor, but with a more futuristic appeal like light blue Led light and a roof fitted with sensors. The equipping motor is 55 kW, there is the 4-wheel drive option, the battery guarantee lasts 10 years and the basic price is 50,000 dollars.

Thanks to Monarch Tractor, the farmer can let his tractor work autonomously, controlling everything through the dedicated app, enabling the management of a whole vehicle fleet, too.

However, that is not all: through the data collection, it is possible to know field conditions in real time. If necessary, the tractor can also become a storage battery, with a sufficient power supply for the recharge of an electric car.

The release on the market is expected for the end of 2021, but the company has recently announced the first deployment of its flagship tractor at Wente Vineyards, the oldest, continuously operated family winery in the United States. This is the first of 15 pilot series deployments prior to its production deliveries in Q4 of 2021 as the company continues to electrify the agriculture industry globally.

«We are thrilled to announce the ahead-of-schedule deployment of the first of several Monarch Tractors,” said Praveen Penmetsa, chief executive officer, Monarch Tractor. “Our tractor has undergone strenuous real-world testing and is now ready to get to work and deliver on the promise of a more sustainable and efficient farming operation».

Weg Electric motors: a more severe ecodesign regulation is imminent

We are at the end: on July 1st 2021, the new ecodesign requirements extended by EU Commission Regulation EU 640/2009 will come into force.

The very ready companies for change, which have sent reminders to their business network, include Weg, with a video that has highlighted the imminent regulatory changes decided and announced last October 25th 2019: the tightening of minimum energy requisites for electric motors with the Regulation (EU) 2019/1781, in force until next June 30th.

The new regulation requires all new 2-, 4-, 6- and 9-pole motors power range 0.75-1000kW to meet IE3 efficiency class. Motor sizes from 0.12-0.75 kW will be required to meet IE2 efficiency class.

From July 2021, hazardous area motors entering the supply chain must be IE2 or IE3 rated.

Weg informs that its hazardous area motors meet the new energy efficiency standards and have done long before these regulatory changes were announced. In fact, WEG also has a super-premium range of safe area and hazardous area IE4 motors.

In a second phase, in fact, starting from July 1st 2023, the even higher Super Premium IE4 efficiency class will be applied to medium-size motors (75 kW–200 kW). For the first time, the EU holds a world leader ranking concerning the minimum requisites of motors’ efficiency.

Europe believes in electric motors

When companies, institutions and universities meet synergistically, innovation explodes with its whole vital force, able to change substantially the future of technology, in this case of electric mobility.

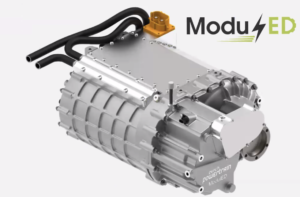

This was confirmed last April 16th, during the presentation event of 3 H2020-projects about automotive funded by EU: ModulED, Drivemode and ReFreeDrive.

Their final joint GVA04 workshop highlighted the modalities with which they faced the challenge issued by H2020 call “Next generation electric drivetrains for fully electric vehicles, focusing on high efficiency and low cost”.

Spotlights were cast on the functional system integration of electric machines; reduced need for rare earth magnets; integration of power electronics with battery charging functions and modular electric powertrain components.

The event was introduced by Philippe Vangeel, Secretary General of AVERE, European Association for Electromobility that has a vision for Europe involving a strong electromobility industry, clean, quiet and healthy cities, energy efficient transport and independence from fossil fuels. “Decarbonising transport is a top priority; we have the solution to do it: electrify the transport! The aim is 100% electrification by 2030 and reaching carbon neutrality by 2050”.

The event was introduced by Philippe Vangeel, Secretary General of AVERE, European Association for Electromobility that has a vision for Europe involving a strong electromobility industry, clean, quiet and healthy cities, energy efficient transport and independence from fossil fuels. “Decarbonising transport is a top priority; we have the solution to do it: electrify the transport! The aim is 100% electrification by 2030 and reaching carbon neutrality by 2050”.

The event focused on short presentations of each project.

The objectives of Drivemode project, presented by Mehrnaz Farzam Far from VVT, are developing efficient and cost-effective drivetrain modules for distributed drive concept. The motivations for integrated module are simplified installation for OEM, reduced material usage and the achievement of optimal synergy among components. The targets for distributed drivetrain, instead, are single design for large variety of vehicles, more flexibility in layout and better control and more functionality.

The motivations for integrated module are simplified installation for OEM, reduced material usage and the achievement of optimal synergy among components. The targets for distributed drivetrain, instead, are single design for large variety of vehicles, more flexibility in layout and better control and more functionality.

Proceeding to ReFreeDrive project, started in October 2017 and ended in March 2021, the speaker Alicia Rodriguez, from the coordinator company Cidaud and Giuseppe Fabri from University of L’Aquila explained the main goal is avoiding the use of rare earth magnets through the development of next generation of scalable electric drivetrains.

Proceeding to ReFreeDrive project, started in October 2017 and ended in March 2021, the speaker Alicia Rodriguez, from the coordinator company Cidaud and Giuseppe Fabri from University of L’Aquila explained the main goal is avoiding the use of rare earth magnets through the development of next generation of scalable electric drivetrains.

Both Induction Motor and SynRel machine are nowadays under evaluation as alternative solutions for mass production in automotive applications, as both show good performance based on low-cost materials and eliminate the supply risks associated with critical rare earth materials.

Both Induction Motor and SynRel machine are nowadays under evaluation as alternative solutions for mass production in automotive applications, as both show good performance based on low-cost materials and eliminate the supply risks associated with critical rare earth materials.

Finally, ModulED Project, presented by Wouter Tits, Punch Powertrain, pursued the technical goals of reaching multiphase high speed motor design with reduced rare-earth magnets, wide bandgap GaN inverter with improved fault-tolerance, dual speed transmission design, optimized thermal management system, improved regenerative braking strategy and virtual assessment tool for sizing and optimizing.

Finally, ModulED Project, presented by Wouter Tits, Punch Powertrain, pursued the technical goals of reaching multiphase high speed motor design with reduced rare-earth magnets, wide bandgap GaN inverter with improved fault-tolerance, dual speed transmission design, optimized thermal management system, improved regenerative braking strategy and virtual assessment tool for sizing and optimizing.

Interesting final remarks about EU funding programme were expressed by Michal Klima, project officer of CINEA, European Climate, Infrastructure and Environment Executive Agency, who ended by confirming the focus on electric mobility of next European calls expected.

Electric Motors Talks, great success for “High-Efficiency Motors and Testing”

Last April 14th took place the first meeting of the cycle of technical insights “Electric Motors Talks”, a digital initiative by University of L’Aquila and Coiltech, as response to the cancellation of Coiltech Deutschland 2021 exhibition scheduled in May.

Spotlights were cast on tests and the high efficiency of electric motors, with the attendance of representatives of the academic world and of the industrial field: research and production, on the other hand, are the key pair for sector developments and its innovation potential.

Prof. Marco Villani, from University of L’Aquila and technical manager of our review Electric Motor Engineering, published by Tecniche Nuove, chaired the meeting. In the course of the event, Prof. Edoardo Fiorucci, from University of L’Aquila, intervened, focusing the attention on the uncertainty evaluations in efficiency measurements. He explained a concept to give a numeric estimation of the measurement quality.

It is probable to obtain different measurement results even for the same parameter of an object under test, if the measurements are performed in different ways, or a different measurement setup is adopted.

Finally, the processing of the extended uncertainties in the measurement or efficiency can lead to additional issues concerning the classification of one tested motor, in comparison to IE efficiency levels.

Another academic speech was by Prof. Alberto Tessarolo from University of Trieste who spoke of Regenerative full-load testing of modular high-power machines that constitutes an alternative to the back-to-back method. The professor assessed that off-shore wind generation is expected to grow faster and faster in the next future towards increasing power levels. The direct-drive solution is one of the most promising thanks to its reliability. However, this solution issues committing challenges in terms of generator manufacturing and factory testing.

Design of Electric Motors for the Automotive Applications 12/05/2021 10.30-12.00; 14:30-16:00

Cooling of Electric Motors 26/05/2021 10.30-12.00

Magnetic Materials 09/06/2021 10.30-12.00

Manufacturing of Electric Motors for the Automotive Industry 23/06/2021 10.30-12.00

Insulating Materials 07/07/2021 10.30-12.00

The relator has explained how vibrations’ behaviour has been investigated to get a very low torque and force ripples by means of multidisciplinary optimization.

Some solutions of Rare Earth free SR motors developed by Spin Applicazioni Magnetiche are also presented for different power and speed values, including a detailed comparison between simulation and test results concerning the electromagnetic and vibration response of the motor.

SR motors and Ferrite PMASR versions are now suitable for low-cost / high-performance use in e-mobility, industrial and automation applications.

Moreover, Dragana Popovic Renella from Senis AG company, went into the detail of the fast magnetic angle sensor for smooth motor control: Senis is moving the limits of the feasible in magnetometry and sensor technology.

Sebastian Kuester, CEO of Quickfairs, ended the event and reminded next meetings of Webinar cycle.

(by Lara Morandotti)

Forefront circuits for the full electric Volvo SUV

SUV XC40 Recharge by Volvo brand will be equipped with Analog Devices technology.

In the specific case, it will be provided with integrated circuits (IC) by ADI for the BMS – Battery Management System and for the Automotive Audio Bus® (A2B).

This model ranked among the finalists in the commercial vehicle category of the North American Car, Truck and Utility Vehicle of the Year™ Awards 2021 of Nactoy, the Awards that reward the best vehicles of the year. Assignment criteria are excellence in innovation, design, safety, drive experience, driver’s satisfaction and product value.

Vertically entering the technology, BMS performances are fundamental to let XC40 Recharge P8 keep the promise of a silent powerful and emission-free drive experience while integrated circuits satisfy the highest global safety standards and can be implemented on several battery typologies, for instance cobalt-free ones, par example the more socially and environmentally sustainable lithium-iron-phosphate (LIP).

ADI circuits provide accuracy along the entire vehicle service life, significantly increasing kilometres per charge and represent a scalable solution on the whole vehicle fleet, from hybrid to full electric vehicles.

Audio solutions based on A2B and on Sharc® audio processor by Analog Devices offer a better experience in the car interior, in sustainable manner: ADI solutions allow connecting the audio system in a low latency bus architecture that assures high audio fidelity and allows saving up to 50 kg of cables and insulation panels in the vehicle. Besides, decreasing the vehicle weight and maximising autonomy, these technologies allow reaching an overall interesting cost for the electric vehicle.

Components, Ethical UK’s growing electric car industry

Good young news from UK: Evtec Automotive, an electric vehicle automotive supply specialist, has set out plans to bolster the future of the UK car industry and shore up the supplier base with a new ethical, sustainable approach to business.

The newly formed, Coventry-based company makes car parts for many of the major players in the UK automotive sector with a major focus on supporting Britain’s growing electric vehicle sector.

«Our mission – said David Roberts, Chairperson Evtec Automotive – is to source, make, deliver and then sustainably dispose of all EV technologies, helping to drive social change and the adoption of zero-emission vehicles. We are rebuilding with purpose. That is our ethos. We are employing more disadvantaged people, driving profit to create social value and making the planet a better place for our children and grandchildren. It can’t get any better».

Evtec Automotive recently acquired Arlington Engineered Systems, that was part of Arlington Industries Group and has been working hard on filling its Coventry plant’s order books. Monthly sales are now back to pre-crisis levels, and it is on target to achieve its employment strategy by end of March 2021, with 35% of jobs being given to disabled workers.

Evtech’s 80,000 sq. ft plant has long employed disabled workers. Originally it was part of Remploy, a scheme formerly sponsored by the Department of Work and Pensions to provide on-going sustainable employment for disabled people.