When companies, institutions and universities meet synergistically, innovation explodes with its whole vital force, able to change substantially the future of technology, in this case of electric mobility.

This was confirmed last April 16th, during the presentation event of 3 H2020-projects about automotive funded by EU: ModulED, Drivemode and ReFreeDrive.

Their final joint GVA04 workshop highlighted the modalities with which they faced the challenge issued by H2020 call “Next generation electric drivetrains for fully electric vehicles, focusing on high efficiency and low cost”.

Spotlights were cast on the functional system integration of electric machines; reduced need for rare earth magnets; integration of power electronics with battery charging functions and modular electric powertrain components.

The event was introduced by Philippe Vangeel, Secretary General of AVERE, European Association for Electromobility that has a vision for Europe involving a strong electromobility industry, clean, quiet and healthy cities, energy efficient transport and independence from fossil fuels. “Decarbonising transport is a top priority; we have the solution to do it: electrify the transport! The aim is 100% electrification by 2030 and reaching carbon neutrality by 2050”.

The event was introduced by Philippe Vangeel, Secretary General of AVERE, European Association for Electromobility that has a vision for Europe involving a strong electromobility industry, clean, quiet and healthy cities, energy efficient transport and independence from fossil fuels. “Decarbonising transport is a top priority; we have the solution to do it: electrify the transport! The aim is 100% electrification by 2030 and reaching carbon neutrality by 2050”.

The event focused on short presentations of each project.

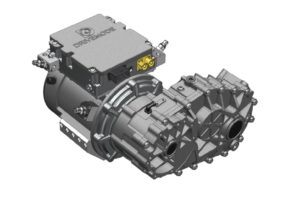

The objectives of Drivemode project, presented by Mehrnaz Farzam Far from VVT, are developing efficient and cost-effective drivetrain modules for distributed drive concept. The motivations for integrated module are simplified installation for OEM, reduced material usage and the achievement of optimal synergy among components. The targets for distributed drivetrain, instead, are single design for large variety of vehicles, more flexibility in layout and better control and more functionality.

The motivations for integrated module are simplified installation for OEM, reduced material usage and the achievement of optimal synergy among components. The targets for distributed drivetrain, instead, are single design for large variety of vehicles, more flexibility in layout and better control and more functionality.

Proceeding to ReFreeDrive project, started in October 2017 and ended in March 2021, the speaker Alicia Rodriguez, from the coordinator company Cidaud and Giuseppe Fabri from University of L’Aquila explained the main goal is avoiding the use of rare earth magnets through the development of next generation of scalable electric drivetrains.

Proceeding to ReFreeDrive project, started in October 2017 and ended in March 2021, the speaker Alicia Rodriguez, from the coordinator company Cidaud and Giuseppe Fabri from University of L’Aquila explained the main goal is avoiding the use of rare earth magnets through the development of next generation of scalable electric drivetrains.

Both Induction Motor and SynRel machine are nowadays under evaluation as alternative solutions for mass production in automotive applications, as both show good performance based on low-cost materials and eliminate the supply risks associated with critical rare earth materials.

Both Induction Motor and SynRel machine are nowadays under evaluation as alternative solutions for mass production in automotive applications, as both show good performance based on low-cost materials and eliminate the supply risks associated with critical rare earth materials.

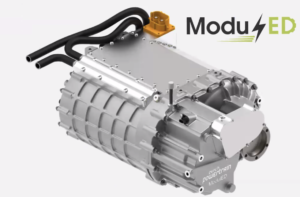

Finally, ModulED Project, presented by Wouter Tits, Punch Powertrain, pursued the technical goals of reaching multiphase high speed motor design with reduced rare-earth magnets, wide bandgap GaN inverter with improved fault-tolerance, dual speed transmission design, optimized thermal management system, improved regenerative braking strategy and virtual assessment tool for sizing and optimizing.

Finally, ModulED Project, presented by Wouter Tits, Punch Powertrain, pursued the technical goals of reaching multiphase high speed motor design with reduced rare-earth magnets, wide bandgap GaN inverter with improved fault-tolerance, dual speed transmission design, optimized thermal management system, improved regenerative braking strategy and virtual assessment tool for sizing and optimizing.

Interesting final remarks about EU funding programme were expressed by Michal Klima, project officer of CINEA, European Climate, Infrastructure and Environment Executive Agency, who ended by confirming the focus on electric mobility of next European calls expected.