MECSPE is back to BolognaFiere from 29th to 31st March 2023, with several novelties and an exhibition core entitled “Energy transition and mobility of the future”.

An intense year has recently ended for the manufacturing industry, driving sector of the economy of the Country that faces 2023 with more confidence [1] and with a rising turnover (+1.9%)[2] and new important targets to be reached.

Among them, enterprises will certainly have to process new solutions constantly in the name of environmental sustainability, process innovation and competence development.

To succeed in it, they will have the possibility of relying, also in 2023, on MECSPE, the main Italian trade fair dedicated to the manufacturing industry organized by Senaf that will be held from 29th to 31st March 2023 at BolognaFiere, through a programme studded with special initiatives, conventions and institutional speeches on the three big exhibition pillars: training, innovation and sustainability.

Sustainability is the protagonist

The latter is the protagonist of MECSPE trade fair core, and exhibition area taking up 2,000 sq.m. entitled Energy transition and mobility of the future, where experts, professionals, entrepreneurs and institutional personalities will have the opportunity of discussing about the innovations in the field of the energy transition and of mobility, from electric vehicles to hydrogen ones, up to biofuels, and visitors will be allowed visiting demo units in operation, which will show technologies and machining intended for the sector of the sustainable mobility, from design to manufacturing, everything according to a logic of circularity and of optimization of the energy efficiency.

The debate will concern the whole supply chain that looks at new more sustainable processes, being extended also to topical issues in the manufacturing sector ambit such as the reshoring, the remanufacturing and the metal replacement, with a focus on new materials.

To enhance the good practices of those who are already committed in the environmental sustainability field, MECSPE confirms also in 2023 Ecofriendly – I do more, a real virtual path among the exhibitors that stand out with new solutions that are source of inspiration for visitors.

Moreover, a novelty of this edition will be Green Plastix Arena, an area where the companies in the rubber-plastic sector will present their innovations based on the concept of circular economy, where digitalization represents a key factor for the efficiency of the resource management.

Orientation, training and recruiting

Broad room also for training and recruiting, with the return of Mecspe Young & Career, a place of meeting between the job demand and supply in the manufacturing industry, for highly specialized figures.

Furthermore, to facilitate the talent search in precision engineering, novelty of 2023 is the Mould and die Training Square, which will connect young future professionals and companies to create new synergies, due to the numerous professional opportunities in the tool sector.

The venue of fundamental times of orientation and training in industry 4.0 ambit will be the Competence Center Area, inside of which new concrete projects will be presented, implemented in collaboration with the manufacturing industry, to meet the requisites of innovation, efficiency and sustainability.

Part of the area will be also the Digital Innovation Hubs, incubators of ideas able to speed up enterprises’ manufacturing processes and at disposal to offer visitors all useful information for the digital transformation of business processes and the support to companies in the processing of projects 4.0.

Conventions, conferences and awards

For over twenty years, MECSPE has been the Italian pole for the technological innovation in industrial field, element on which the exhibition is based, which every year proposes solutions for industry 4.0, and also in this edition times of meeting and discussion dedicated to companies’ innovation and digitalization will not miss.

Starting from the Additive Manufacturing Arena, the space hosting conventions about new additive technologies, enlivened by speeches about real projects, technical presentations, case histories of excellence and institutional speeches.

For all the players involved in research and development processes the Simulation Summit is instead back, the first Italian independent conference on CAE Simulation in industrial ambit, conceived with the aim of promoting the engineering Simulation.

With a view to encouraging innovation in development processes and acknowledging the commitment of those driving the change in industry, on March 30th the prizegiving of the Solution Award will be held, the Robotic Innovation award, which will be given to enterprises standing out for the best industrial or service robotic application.

Focus on innovation also by the Startup Factory, which has reached its third edition, an area to favour the dialogue among start-ups and small, medium and big enterprises coming from the manufacturing industry.

The Engineering and Design Square is back, too, and with a focus on the theme of materials’ transparency, this time it is centred on the aesthetics and design of the items on show.

«At each edition MECSPE tries modulating programme and initiatives according to enterprises’ real requirements, with the goal of supporting them in the growth process, for which we believe it is fundamental to boost the comparison and the mutual exchange of business expertise and practices – affirms Maruska Sabato, Project Manager of MECSPE – For 21 editions, the manufacturing field has met at MECSPE precisely with this spirit, and the results achieved confirm how much is important, for the chain protagonists, to meet in a highly professional context, rich in contents that look at the sector future.»

Associations, the fair’s added value

MECSPE convention programme will be enriched by the attending associations during all three trade fair days, which bring added value to the event due to their precious contributions.

Among them, MESAP, the innovation cluster for the Smart Products and the Smart Manufacturing of Piedmont Region, AIFM –Italian Association of Metal Finishing, present with its A.I.F.M. Finish Area, and CNA Production, the CNA area that represents the biggest representation association distributed on the territory.

The Italian association of Plastic Material Technicians will take care of TMP Square, meeting point for the network, aimed at the exchange of know-how for plastic material technicians.

Large room also for Confartigianato, with Confartigianato Village, companies’ lively collective showroom that also on this occasion will be accompanied by a series of events.

Many associations will take part with dedicated collective areas to develop the entrepreneurial fabric’s excellence of the various districts.

Among them, in the ambit of the Mechanical Subcontracting Showroom, the Associations of Small and Medium Enterprises, API,will be present, from the districts of Brescia, Torino and Lecco, the Cluster of Metalworking in Friuli-Venezia Giulia COMET and the association of manufacturing enterprises CONFIMI Romagna.

In the showroom Machines & Tools will be instead hosted the ASCOMUT Village, which represents import and distribution enterprises and the branches of foreign companies in the sectors of machine tools and tools.

Moreover, an international collective organized by AFM Machine Tools Manufacturing Cluster, the Spanish Association of machine tool manufacturers, will be present.

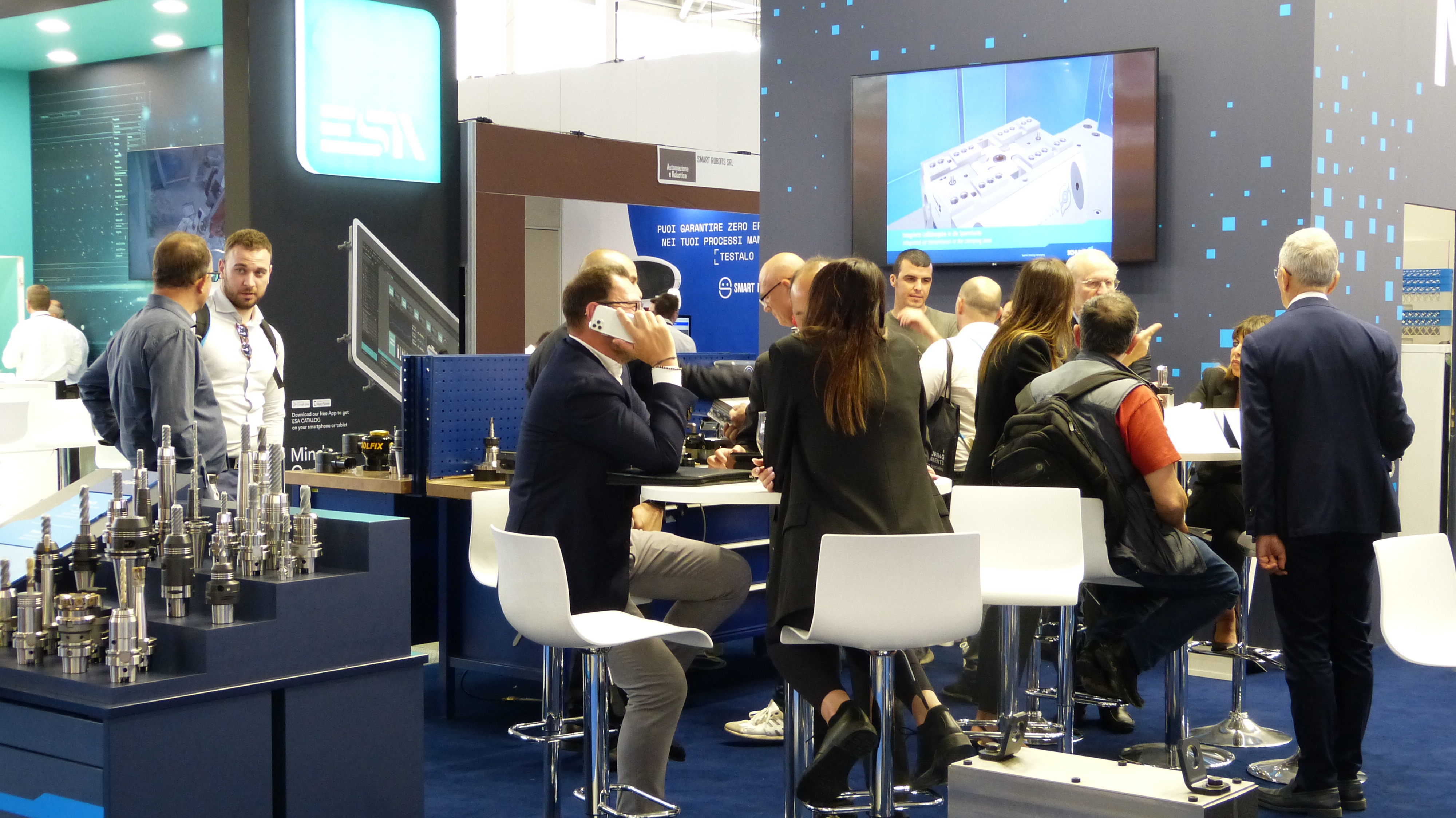

The specialized areas inside the Automation and Robotics Showroom will include Aidam Village, the space reserved to member companies operating in the Automation and Mechatronics sectors, Assogalvanica, the Italian Association of Galvanic Industries and also CDO Networking Business Area, by Cdo Compagnia delle Opere.

The first time for Elettronica Italia

Moreover, starting from this year, Elettronica Italia event will be held simultaneously with MECSPE; it is fully dedicated to the electronics world and provides visitors with an outlook on the whole field and a focus dedicated to electronics at the service of the electric mobility and transport electrification.

Still simultaneously with MECSPE also METEF will take place, the international expo dedicated to the aluminium chain, a central branch for the industrial sustainable manufacturing.

“Focus Mediterraneo” in Bari

Finally, in 2023 MECSPE will double the meeting and will be held also in Bari from 23rd to 25th November with “Focus Mediterraneo” at Nuova Fiera del Levante, an edition dedicated to the development of technologies 4.0 and a proposal increasingly focused on sustainability and innovation of manufacturing processes.

[1] Istat source, companies’ confidence

[2] Istat source, industry’s turnover in August-October 2022 quarter