The success story of GROB-WERKE began back in 1926 when the company was founded by Ernst Grob, who was producing folding boats, weaving machines and stationary combustion engines at that time.

In 1952, Burkhart Grob, the son of the founder, assumed responsibility for the company almost completely destroyed during the war and was able to forge the link to the emerging automotive industry with high-quality and technologically-convincing production machines. In 1968, the Mindelheim plant was built and the company’s headquarters was relocated from Munich to Mindelheim. Besides the parent plant in Mindelheim, the plants in Bluffton (USA), São Paulo (Brazil), Dalian (People’s Republic of China) and Turin (Italy) are part of the production network of GROB Group. This production network is expanded through fifteen sales and service branches in South Korea, China, India, Russia, Great Britain, Hungary, Mexico, Poland, Switzerland, the Netherlands, Vietnam, France, Japan and the USA to guarantee the best service quality.

Even after Dr. Burkhart Grob passed away in May 2016, the future of the family company has been strictly set out. Christian Grob took the company into the third generation as the new Supervisory Board Chairman. With a product portfolio ranging from universal machining centers to highly complex manufacturing systems including automation, and from machining assembly units to fully-automated assembly lines, GROB is one of the few machine tool manufacturers that produces and supplies machining and assembly equipment, as well as electromobility concepts since 2016.

Since the production of electric motors demands special assembly know-how, it was logical for GROB to seek a competent partner from the field of electric motor technology. Its takeover of DMG meccanica enables GROB to emphasize more than ever its claim in drive technology to be a leading and reliable partner for the automotive industry.

Development of DMG meccanica

Mauro Marzolla and the father of Marco Debilio founded DMG meccanica in 1992. They both brought with them decades of experience in winding technology for electric motors acquired at PAVESI, which, at that time, was one of the leading Italian providers of winding machines for electric motors. In 2001, after PAVESI had closed the activity definitively, DMG meccanica enjoyed an extremely successful period during which a range of new technologies and invention were brought to the market. These included both solutions and machines for manufacturing stators for electric motors, alternators and generators, and solutions for highly efficient winding machines. Directly responsible for these technological milestones were the engineers of DMG meccanica, who are among the best in their industry. Following this development, further products were developed over the years, such as various machines for spool manufacturing, spool feeding and winding head forming and slot insulation machines. In 2016, DMG meccanica, with a workforce of forty employees, achieved a turnover of ten million Euro. Five percent was in the home market of Italy, 40 percent in the EU and 55 percent in non-EU countries. 60% of the customer portfolio is comprised of well-known electric motor manufacturers and suppliers to the automotive industry. In addition, DMG meccanica was particularly well-represented in the important e-mobility market of China.

The acquisition: benefits for both companies

At the end of January 2017, GROB acquired 100 percent shares in DMG meccanica, substantially reinforcing the competences and developments in electromobility which it has been developing for several years. The technologies of DMG meccanica and the new processes developed by GROB, enable GROB to provide all the vital manufacturing processes and procedures in electric drives for the automotive industry and its suppliers world-wide, and also to supply them for series production in the near future. Following the acquisition, DMG meccanica became part of the GROB Group without any changes being made to its corporate structure. To complete its integration and optimize its structure, DMG meccanica has undergone the final step of the acquisition and been renamed GROB Italy S.r.l. in January 2018. The management board remained unchanged and continued to comprise the founders of DMG meccanica Mr. Marco Debilio and Mr. Mauro Marzolla.

The cooperation was a win-win situation for both companies. GROB took this step in order to strengthen its many years of research and development work in the field of electromobility and DMG meccanica has found in GROB a strong, globally-oriented partner for series production.

Further investments to expand these technologies are planned at both sites in Turin and Mindelheim. So already four years ago, in response to the increasingly progressive pace of technological change with vehicle powertrains, GROB established a Research and Development Team that focused solely on electromobility. Close consultation with renowned representatives from the automotive industry soon revealed a high demand for mass production equipment in this sector, the focus being on two core areas, the electric motor and the battery. In close collaboration with the automotive industry, engineering processes and methods for the series production of high-efficiency electric motors and extremely compact battery modules with a high power density are being developed and trialed on over 2,500 m² of space. “GROB is currently working on several projects for electric drives in the international automotive industry,” says German Wankmiller, Chairman of the Board & CEO. He goes on to explain: “Thanks to a team of specialists and development engineers, GROB can realize each and every one of these projects. As a general contractor, we are already able to handle large orders and offer machines and systems for electric motors, battery modules and fuel cells.”

Product portfolio

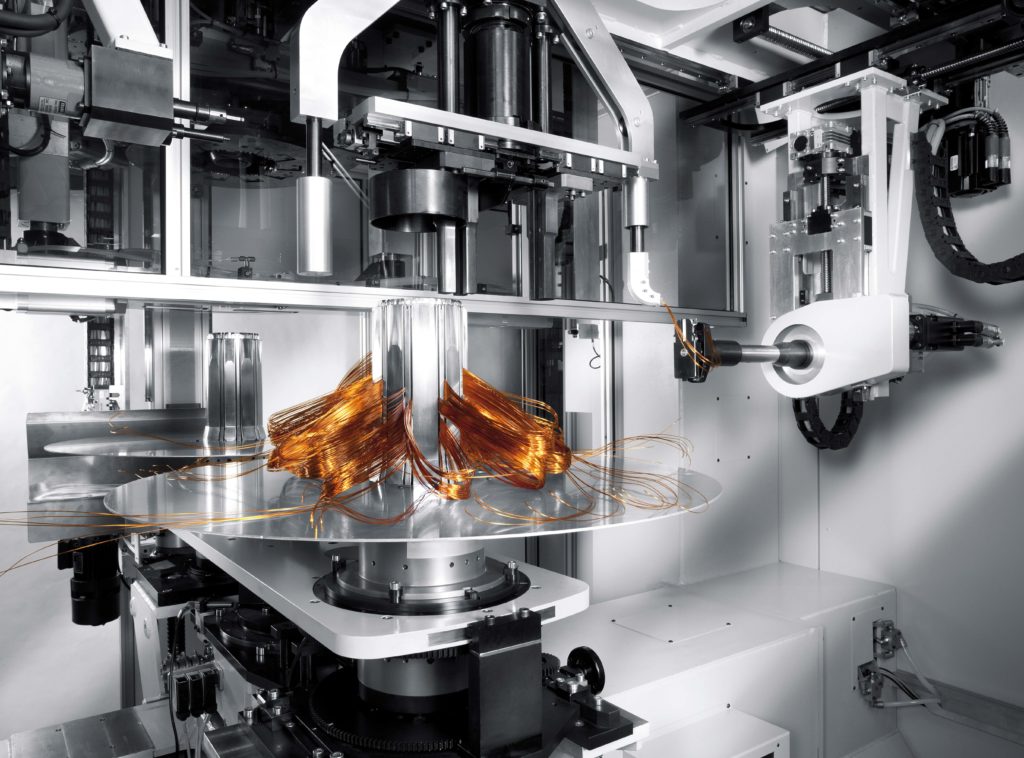

GROB’s innovative prowess in the automotive industry has led to the electric motor and battery being pushed forward into a new technological dimension, and to the development of electric motors achieving high power density and efficiency. The challenge is to manufacture very precise, process-stable and precisely-timed machines and equipment, since very narrow tolerances are vital for achieving efficiency. As a general contractor, GROB offers a wide portfolio of such machines in the field of stator, rotor and electric motor production. The production program ranges from individual semi-automatic machines to fully automated complete solutions. For stator production in particular, there are various manufacturing methods for inserting copper wires into the stator slots. GROB covers the wave winding technology, the hairpin method and the fan coil technology. In addition, GROB Italy S.r.l. offers the inserting technology and needle winding. This means that GROB can market and operate all the production processes required in the automotive industry. GROB supports its customers, from the initial idea to the system concept for prototypes through to large-scale series production. In addition to electric motors, the field of battery systems represents the second most important of the pillars for the future of electric mobility. The production of battery cells and the reliable assembly of battery systems is becoming increasingly important. As a specialist in assembly technology and automation, GROB is ideally positioned as a provider of turnkey equipment to also be capable of providing future-proof and reliable systems engineering in the field of battery systems. To meet the demands of car manufacturers in the field of battery systems, very versatile engineering is required, for which GROB develops new and innovative system concepts focusing on process stability, precision and flexibility, taking cost factors into consideration. With a team of specialists, the GROB technicians work on futureproof production processes and make an important contribution to the development of intelligent concepts from ideas to series production. In module assembly, individual battery cells are processed to form a module. The requirements for battery systems as energy storage systems are tremendously high in terms of product, production technology and safety, and optimal quality is demanded in view of the delicate cell chemistry, so production lines must be fully automated and interlinked. But at the end of the day, the success of production is largely dependent upon understanding and optimization of the overall process. For this reason, GROB offers support to its customers at all stages of the value-added chain the technical know-how needed for this is partly drawn from similar processes in assembly technology.

Relevant markets and future scenarios

Electromobility is gaining importance at an increasingly fast pace, and transformations in vehicle drive technology have already begun. The markets have responded to these changes in various ways. GROB though, with its inherent strength and experience of making highly productive manufacturing and assembly lines, has already squared up to this new challenge. The GROB Group champions a uniform procedure and sales structure, and this is closely coordinated with the headquarters in Mindelheim. Since Europe and China are among the electromobility forerunners and the proportion of e-drives in China for the next few years has been laid down by legislation, investments in this sector are very high. With its expertise as a turn-key supplier, recognized by the automotive industry on many occasions, GROB has already mastered all the processes and technologies required to offer system concepts for reliable and cost-efficient series production. No surprise, then, that GROB is already considered the first point of contact in the electromobility sector – the testimony being the first extensive orders from the automotive industry. In this process, the Italian production plant is playing a key role within the GROB Group alliance to secure positive future prospects for the company.

Ground breaking ceremony of the new GROB Italy plant

The transfer of the GROB Italy plant from Buttigliera Alta to Pianezza is part of a long-term development plan which intends to make Pianezza a place of reference regarding the design and manufacturing of special machines and automation solutions for the production of electric motors. To support this important technological development, GROB has set up the new plant in Pianezza as a highly functional center, with an area of 24,000 square meters, of which 4,800 sm are dedicated to production and 3,300 sm to offices and services. It is intended to pool the whole production cycle from conceiving an idea to its practical implementation. Currently, the financial investment provided is approx. ten million euro. The workforce at the moment comprises about 60 employees, but GROB Italy is planning an increase of about 40 to 50 new jobs in the first phase to meet future needs.