GROB Italy among the few able to perform the whole process of motor manufacturing

The fast progress of the green revolution has imposed a neat change of pace to all big players in the automotive (and non-automotive) industry that, to face the transition to electric, require their partners technical competences to generate innovative, performing and eco-sustainable solutions.

GROB Italy has accepted the challenge with promptness: relying on over thirty years of know how in the manufacturing of machines and lines for the electric motor and being a consolidated partner in the insertion technology, the company can position itself among the most reliable suppliers for Light E-Mobility applications and among the few on the market (the only one in Italy) able to cover the whole motor production process.

The line dedicated to the manufacturing of motors from 4 to 40 kW includes, in fact, winding, impregnation, rotor and assembly and therefore can offer a complete and efficient “turnkey” solution for two-wheelers and three-wheelers, but also microcars, vehicles “for fun” and e-marine.

The line dedicated to the manufacturing of motors from 4 to 40 kW includes, in fact, winding, impregnation, rotor and assembly and therefore can offer a complete and efficient “turnkey” solution for two-wheelers and three-wheelers, but also microcars, vehicles “for fun” and e-marine.

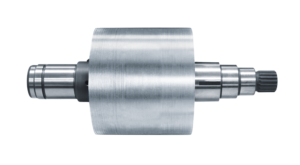

The Italian branch of GROB Group could deploy its expertise also in the production of lines connected with the rotor.

In the rotor line of GROB Italy, the operations of glue distribution and magnet insertion are both managed by robots, to grant high precision and repeatability of the final result. GROB Italy has in fact optimized the rotor manufacturing process by defining a reliable process sequence and a scalable layout according to manufacturing volumes and extending its flexibility to products, from the Light E-Mobility, up to power ranges normally used by both light and heavy commercial vehicles.

Among the most recent innovations, the development of solutions concerning segmented-stator and axial- flux motors are among the most frequent demands submitted to the company. GROB Italy can carry out the joint study and the prototyping of Segmented Stator and Axial Flux motors, with both round wire and rectangular wire conductor.

Highly productive but also sustainable machines: the GIT Connect software allows optimizing energy consumptions, monitoring performances from remote, limiting machine downtimes, executing an immediate check for the problem solving – everything without affecting the high product efficiency.

A company accustomed to manufacturing tailored solutions, both at technological level due to the availability of a Technical Office for studies of simultaneous engineering and prototyping, and in terms of Service and after sales. With a customer service available on a world scale, the company can provide for the training of the GROB service next to the installation site, so that the customer can benefit from immediate and direct service.