A high-speed electric motor and integrated power-electronics allow achieving competitive manufacturing costs. This is highlighted by a recent important job order in the electro-mobility field, where Bosch is protagonist with the supply of fuel-cell components to cellcentric, a 50% joint venture between Daimler Truck and Volvo Group. It is a long-term contract for the supply of electric compressors with integrated power electronics to share in making transports sustainable and neutral for climate by 2050. The component will be part of the fuel cell system of cellcentric for heavy commercial vehicles and for stationary applications. The use of a fuel cell propulsion system that exploits hydrogen allows making the vehicle neutral for climate. The electric compressor supplies the necessary quantity of filtered air and it is therefore one of the fundamental components of the system.

«Bosch – explained Uwe Gackstatter, President of the division Bosch Powertrain Solutions – offers the compressor in two power classes: 20 and 30 kW. The 30-kW size is calibrated for voltages from 450 to 850 volt, whereas the 20-kW one is suitable for 250-450-volt or 450-850-volt voltages. The compressor turbine reaches speeds of over 100,000 rpm. The combination of high-speed electric motor with integrated power electronics allows achieving competitive manufacturing costs. Moreover, silicon carbide semiconductors of silicon carbide used in power electronics by Bosch make this component highly efficient, precisely the characteristics cellcentric was looking for».

Electrical compressors with integrated power electronics

The first electric motor signed by Yamaha

It is recent the news that Yamaha Motor will supply Subaru Tecnica International Inc. (STI) with electric motor units for their STI E-RA EV that STI is developing for future motorsport.

The electric 350 kW motor by Yamaha was in fact protagonist of a test on board of the hypercar Subaru STI E-RA EV.

Featuring a power of as many as 469 HP, Yamaha has developed the motor specifically thinking of the next generation of electric cars and it has designed a compact motor, equipped with cooling system and to be coupled with more units on the same vehicle.

Subaru vehicle that is protagonist of the test was equipped with four STI E-RA EV motors for an overall power of 800 kW that in 2023 aims at surpassing the lap time of 6 minutes and 40 seconds of the famous German Nurburgring track.

Ansys, the importance of tests for electric motors

«We rely so much on electric motors that we often notice them for the first time when they are broken: a problem that can be absolutely prevented, through the tests on electric motors», writes Ansys in a press release, giving broad room to the importance of tests on electric motors carried out during all phases of their lifecycle. Even if the specific tests executed will vary according to the complexity of the motor, of its application and of the parameters to be assessed, some of the key tests used during the tests on electric motors include electrical tests such as polarity checks and voltage level measurements and vibration tests to detect any imbalances or misalignments.

There are also thermal tests to monitor the motor’s temperature to avoid overheating, dynamic tests to see how the motor performs in transient states, noise tests to evaluate acoustic characteristics against sound standards and, finally, insulation tests to ensure the motor’s insulation materials won’t degrade while operating.

In each application where electric motors are used, from industrial compressors to dental drills, tests validate that a motor satisfies the specifications established by the manufacturer and the quality and safety parameters determined by sector standards.

On a world scale, standards such as interoperability and safety are consistent according to each single Country, while local standards can include requisites that acknowledge the Country’s specific priorities, such as environment and culture.

A following step? The use of simulation in the tests on electric motors improves the speed, the efficiency of the test process itself, the quality, the depth and the reliability or certainty of the collected data. Simulation software like Ansys Maxwell and Ansys Motor-CAD can perform coupled multi-physical calculations, providing technicians with in-depth estimates of complex systems, evaluations that would be unfeasible with a test at a time.

Metals to make electric motors. What future?

According to a study published by the Belgian University KU Leuven and commissioned by the European association of non-ferrous metal manufacturers Eurometaux, the transition towards sustainability will need 33% of aluminium more by 2050 versus current consumptions, owing to the bigger demand driven by electric vehicles, photovoltaic and development of electric networks.

The consequence? In Europe, around 2030, some problems might emerge because of the global provisioning shortage of metals, especially of lithium, cobalt, nickel, rare earths and copper, while the demand will reach the peak by 2040 approximately.

Let us go into the specific detail. European Union Countries will need a higher quantity of metals than today: 35% of additional copper will be necessary, 45% more silicon, whereas the supplies of nickel are expected to rise by 103% and cobalt ones by 330%. Not to mention the European demand for lithium, whose requirement will be higher by 3535% and of rare earths like dysprosium, needed with +2666% and neodymium, with +827%.

KU Leuven experts state domestic mines could potentially satisfy from 5% to 55% of the European requirements of metals for the energy transition in 2030.

What is the solution? On the medium-long term, recycling will be the key that will allow solving partly these problems along the provisioning chain.

STILL enlarges its electric offer

The protagonist for over 100 years with intralogistics solutions, STILL has decided to widen its range of products by proposing two specific lines to the market: the new ‘Classic – Line’ and the consolidated ‘Xcellence –Line’. Some of the forklifts already present in the current STILL range are now part of the new C-Line: for instance, the series of RCE 25/35 electric fronts released by the company in April 2023, characterized by notable energy efficiency, low battery consumption, and reduced maintenance.

Moreover, the C-Line includes also ECH pallet trucks with capacities of 1200 and 1500 kg and the possibility of choosing the ECH 15 model with 48V battery and stabilizing wheels. The C-Line range includes also ECV lifts with a loading capacity of 1000 kg, available in different configurations, such as simple and telescopic columns and with initial lift. Still by Still comes an emblematic piece of news that represents a step forward in the modernization and electrification of handling operations for the flight ambit.

They have recently delivered an electric STILL RCE 30 forklift to the flight department of the State Police: equipped with a high-performance AC motor, excellent 360-degree visibility, and the option of automatically regulated speed in a curve, it has been chosen to grant operational efficiency, without polluting.

Motorvalley, the production of Ducati MotoE is starting

Just over a year after the first test with Michele Pirro at Misano World Circuit Marco Simoncelli, they have started the implementation of “V21L” prototypes that will be protagonists of the 2023-season of FIM Enel MotoE™ World Championship.

The start of the production of “V21L” prototypes represents the beginning of a new important chapter in Ducati’s history: the project was born with the aim of developing competences for one’ own future, maintaining the approach that has always driven Ducati DNA, then experimenting technological solutions in the competitions’ world and working so that all that is developed in this ambit can then land in the motorbikes intended for lovers all over the world.

To succeed in it, they have manufactured a technological sophisticated electric motorbike, fruit of the joint work of Ducati R&D engineers and of Ducati Race team. Claudio Domenicali, CEO of Ducati declared: «The start of Ducati MotoE production is a historical time for our company, which with this project is studying in-depth the future technologies of the two-wheelers’ world. It is an important experimentation ambit, where we are investing to build know-how, to be ready if and when the battery technology could allow the production of a really exciting electric street bike, then expected to have weight, performance and autonomy wished by lovers from a Rossa from Borgo Panigale».

IE3 energy efficiency starting from 0.09 kW

In Europe, the 640/2009 Regulation on electric asynchronous motors, which has been transposed in more phases, has been in force for some years now. Currently, the regulation concerns 50 Hz or 50Hz/60Hz three-phase asynchronous motors, for constant operation, with nominal powers between 0.75 kW and 375 kW, with 2, 4 and 6 poles; the energy efficiency class for use in net must be minimum IE3 for them.

The new DRN motors constitute integral part of our modular system of motors. A new interface with mechanical reducer, able to assure higher flexibility and system combination. With optimized weight, sizes and efficiency, these asynchronous motors can be easily integrated into machines and plants for high energy-efficiency operation. The new IE3 motors are naturally compliant with all main global specifications and design regulations like IEC 60034, NEMA MG1, UL 1004-1, CSA C22.2-100, ABNT 17094-1 and GB 12350 (CCC). Moreover, they already conform to the next regulations in the energy efficiency field for Europe, India, Brazil, USA, Canada, China and other Countries.

All this makes Sew-Eurodrive an outstanding manufacturer of low energy consumption gearmotors of the IE3 efficiency class, with nominal powers included between 90 and 200 watts, with all customary quality and a complete line of services connected with the product that operators know and appreciate.

Battery system simulation software

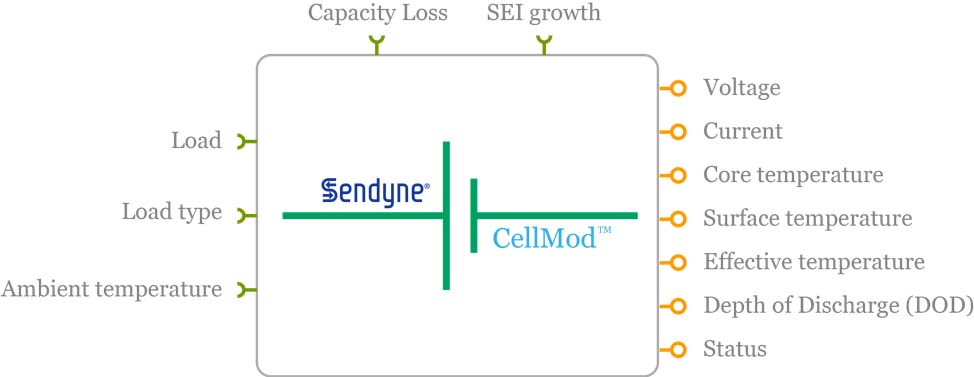

To Support Advanced Electric Vehicle Battery Systems Design, Altair, a global technology company providing solutions in product development, high-performance computing and data intelligence has announced the addition of the CellMod™ Virtual Battery by Sendyne to the Altair Partner Alliance (APA). So, CellMod™ Virtual Battery and BasicPackMod by Sendyne are now available for use by Altair HyperWorks™ customers.

CellMod™ is the first lithium-ion virtual battery capable of predicting cell and pack behavior, including thermal behavior, with an accuracy of better than 97 percent under a wide range of test conditions. Utilizing a sophisticated electrochemical model, CellMod is packaged as a functional mock-up unit (FMU), allowing it to be easily integrated into most major simulation packages, such as Altair Activate®, via the open industry standard functional mock-up interface (FMI).

After all, improving battery system performance is critical to facilitating the projected global electric vehicle market growth. An accurate battery model is the starting point for battery pack design, system control and optimization. The simple equivalent circuit (EC) models that are typically used today lack predictive power and are insufficient to the task. Taking a physics-based approach to simulating integrated systems that is accurate and runs faster than real-time can significantly improve the design of battery-based systems and optimize their long-term performance and safety.

Unlike EC models, CellMod accounts for physical processes taking place inside the cells, including diffusion in solids, diffusion in electrolytic solutions, reaction kinetics, charge transport, heat transport, etc. Because of this, CellMod can predict battery cell behavior with a high degree of accuracy.

Industrial energy saving opportunities for motor-driven systems

Upgrading to energy efficient technology is one of the simplest and most cost-effective ways to lower energy consumption and associated greenhouse gas emissions. Across the world’s 300 million industrial motor-driven systems, there is potential to cut global electricity demand by up to 10 percent by switching to high-efficiency systems.

A new digital service from ABB will enable industrial operators to maximize energy efficiency and boost su-stainability by identifying motor-driven equipment in their facilities with the best energy-saving potential. The ABB Ability Digital Powertrain Energy Appraisal service will draw on data measured from fleets of digitally connected electric motors and variable speed drives (VSDs) to show where and how much energy can be saved by upgrading to the latest high-efficiency technologies. Industrial operators can then make data-driven decisions when prioritizing investments.

Adrian Guggisberg, Division President of ABB Motion Services said: «The challenge for an industrial operator is knowing where to start in a fleet of hundreds of electrical motors. ABB developed the new Digital Power-train Energy Appraisal service to provide clarity by analyzing motor data and identifying where businesses should focus investment to maximize energy efficiency gains that reduce operating costs and CO2 emissions».

One operator that is reaping the benefits is Waggeryd Cell, a pulp mill in southern Sweden with industry-leading energy efficiency. It wanted to further improve the efficiency of its energy-intensive process by buil-ding on its ABB Ability Condition Monitoring system. This draws data from digitally-connected motors in re-finers, process pumps, fans and conveyor belts. Under the new Digital Powertrain Energy Appraisal service, ABB’s experts used data from the same sources to identify the ten motors with the most potential for improving energy efficiency. Waggeryd has now prioritized replacement of six of these motors to cut energy consumption, as well as greenhouse gas emissions.

The new digital appraisal service uses a plug and play approach to simplify energy efficiency assessments by pulling operational data remotely from across an entire fleet of digitally connected motors.

7.5 million raised for the Sealence project

Sealence Spa SB is the startup that has invented the first fully electric jet for naval propulsion, DeepSpeed. The last funding round, completed last December 15th, ended with 7.556.386,25 due to 175 investors, through equity instruments and debit grants. Resources are mainly intended for the support of experimental research and industrial development activities and it is just another growth step. «The total fundraising since the start of the industrial plan activities overall reaches about 16.5 million Euros, whereas the investments made in industrial research and experimental development activities reach about 9 million Euros».

The target is to be sought in the super-deepspeed motor at the service of more efficient and performing electric boating. To date, the fleet of boats that test electric Sealence motors consists of four boats from 6 to 15 meters. Moreover, it seems that Sealance is designing the building of a gigafactory of batteries.