For the same models with different power supplies, the carbon footprint of electric versions is already better than the one of the corresponding variants with internal-combustion engine. Moreover, electric vehicles provide a higher potential of CO2 reduction in all lifecycle phases of the product. Concerning CO2 emissions, the energy provenience from fossil fuels or renewable sources is fundamental, too. This is the result of a Life Cycle Assessment (LCA) certified by Volkswagen Golf, which compares the CO2 emissions of the different vehicle versions, with electric motor or internal combustion engine.

In short, the current Golf TDI (Diesel) emits on average 140 g of CO2/km along the entire lifecycle whereas e-Golf1 just 119 g of CO2/km. It is clear that, for a vehicle with internal combustion engine, most of emissions come from the use phase, i.e. from the fossil fuel provisioning chain and from combustion: in these cases, the Diesel version reaches 111 g of CO2/km, whereas, in this phase, a corresponding electrically powered vehicle emits only 62 g of CO2/km, deriving from the energy generation and supply. On the contrary, most of emissions for an electric car are generated during the production phase.

According to LCA, the datum referred to the Diesel version is 29 g of CO2/km; whereas the one of a corresponding electrically driven car is 57 g of CO2/km.

The battery production and the complex mining of raw materials weigh significantly, and this number corresponds to almost half of CO2 emissions for the entire lifecycle that, during the use phase, depend on energy production sources – their decrease depends on the availability of renewable energies.

Life Cycle Assessment, electric car wins

Flexible heating at the service of electric mobility

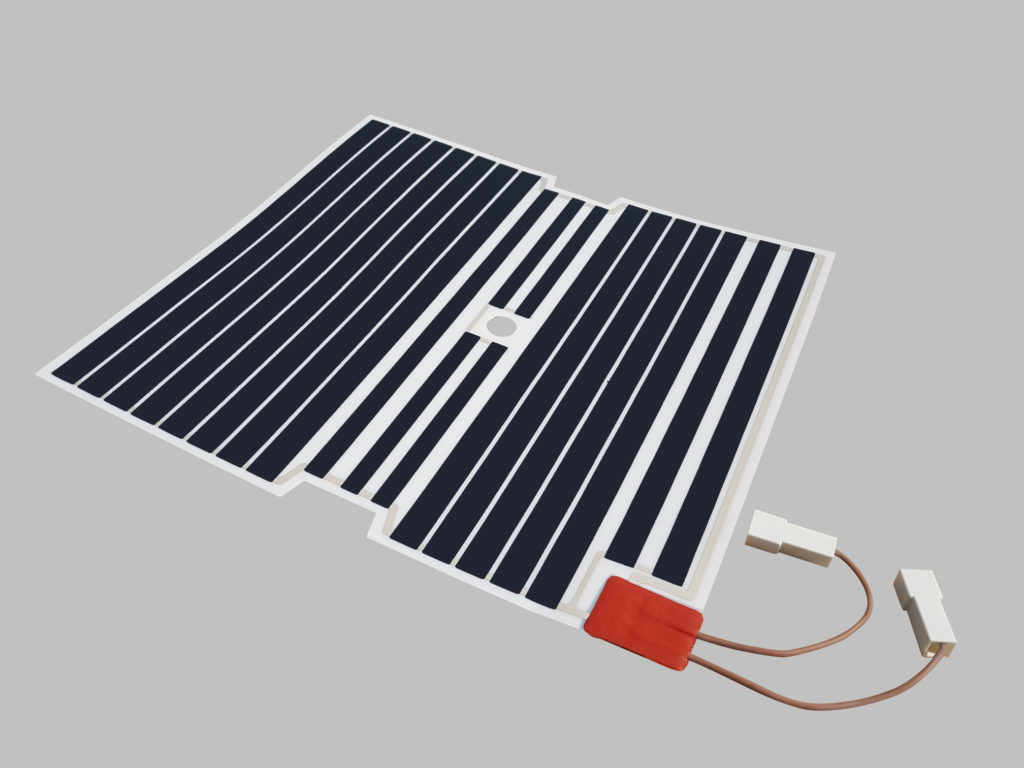

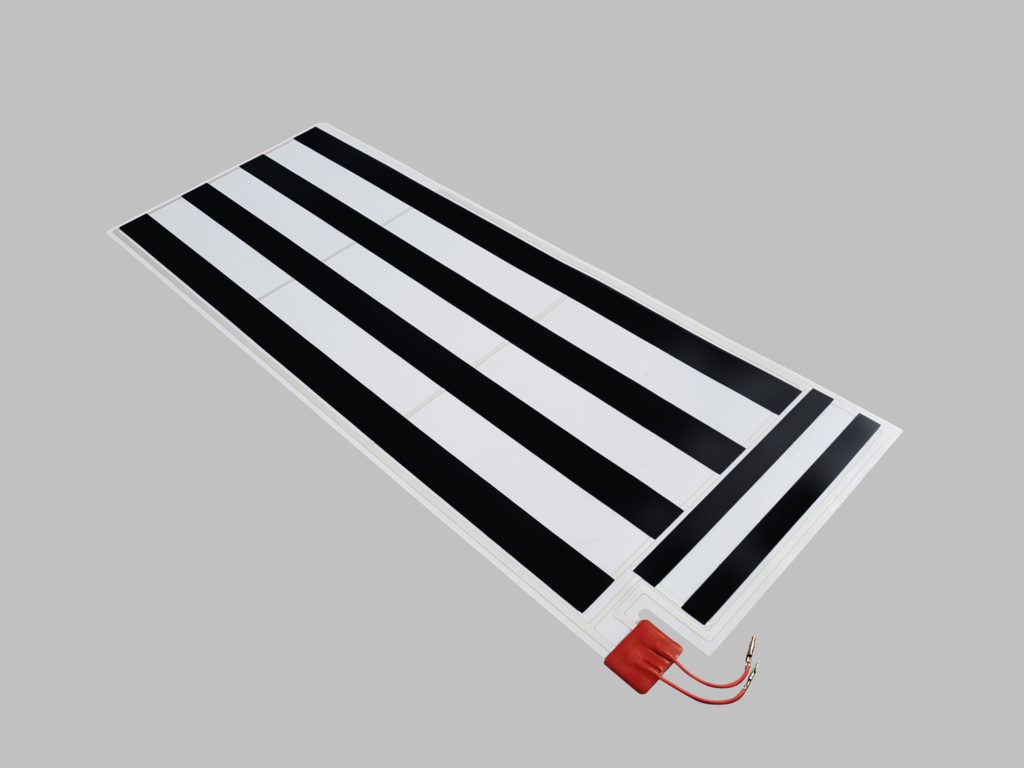

Alper produces polyester flexible heaters, electric and electronic circuits for the most different applications in several sectors. Among them, also the challenging automotive industry, to be meant in its widest scope, addressed by the company with a broad range of customized solutions where stand out those purposely studied for battery packs.

The mobility world is decisively looking at an electric-speaking future. In this context – no matter whether hybrid vehicles, as combination of endothermic and electric motors, or fully electric are at stake – battery packs undoubtedly play a protagonist role. An ambitious challenge accepted also by Alper, flexible heating specialist able to design and manufacture ultra-flat polyester resistances precisely used to make battery packs reliable and performing in time.

«It is known – the owner and general manager, Guido Alessi, explains – that the most diffused and used typologies of Lithium batteries for these applications, outside determinate temperature ranges, cannot always maintain optimal efficiencies.

In temperature conditions below zero, for instance, they can feature some criticalities: to slow down the times needed for their recharge, to consume more energy, to supply less powerful pickups, and therefore to provide minor efficiency. Not fortuitously, for a long time now all manufacturers have attentively considered the so-called Thermal Management, fundamental issue to maintain battery packs at optimal temperatures to provide the best operational conditions».

Technical divisions, research and development departments of battery manufacturers, or directly automotive companies and electric vehicle producers, try then to solve such problems by implementing some devices.

«Concerning the solution of criticalities caused by cold and too low temperatures –Alessi adds – it is common practice to provide for the integration of adequate resistances directly among the cells of battery packs, or as external barrier that heats the chassis».

Another interesting solution allows instead exploiting the already existing liquid cooling system, suitable for regulating the functional heating of the battery at steady-state.

«In this case –Alessi highlights – it is possible to exploit the plates of the liquid cooling system, applying suitable heating elements and a simple 3-way valve. This allows by-passing the radiator entrusted with the standard, to exploit this mini-circuit that becomes the heating source for batteries».

Flexible polyester heating elements for electric batteries

More in detail, Alper ultra-flat resistances allow minimizing the necessary thickness of the heating element (from a minimum of 0.2 mm).

Usable in several application fields, like the broad diversified ambit of e-mobility, such resistances are produced by silk-screen printing, with an additive manufacturing technology, initially depositing silver tracks, for the electric current transport, and afterwards a layer of conductive and heating pastes.

Similar to etched-foils, but much more reliable in terms of flexibility, they assure the highest efficiency levels at the service of low-temperature heat production. The constant research of new heating formulations has allowed the company to make the production capacity and the development of new design products, on customer’s precise specification, very versatile. The technology, unique of its kind, permits to reduce the costs of implementation and of eventual small modifications of the demanded powers (with a significant range of +/-20%) just modifying the composition of the conductive paste (unfeasible thing with etched-foil technology). All that allows implementing electric resistances with very high ohmic value, hardly feasible thing with other alternative technologies on films or with heating cables.

«Peculiarities and features –Alessi specifies – from which can benefit the battery packs designed for cars, trains, bicycles, motorcycles and any other electric vehicle, also used in industrial ambit such as forklifts or in shipbuilding. As many are the operational benefits for the same battery packs deriving from the use of ultra-flat flexible heating elements we design and manufacture: extension of the service life of the battery itself; increment of the good operation also at low temperature; faster recharge times, high temperature uniformity».

The added-value of the additive manufacturing technology

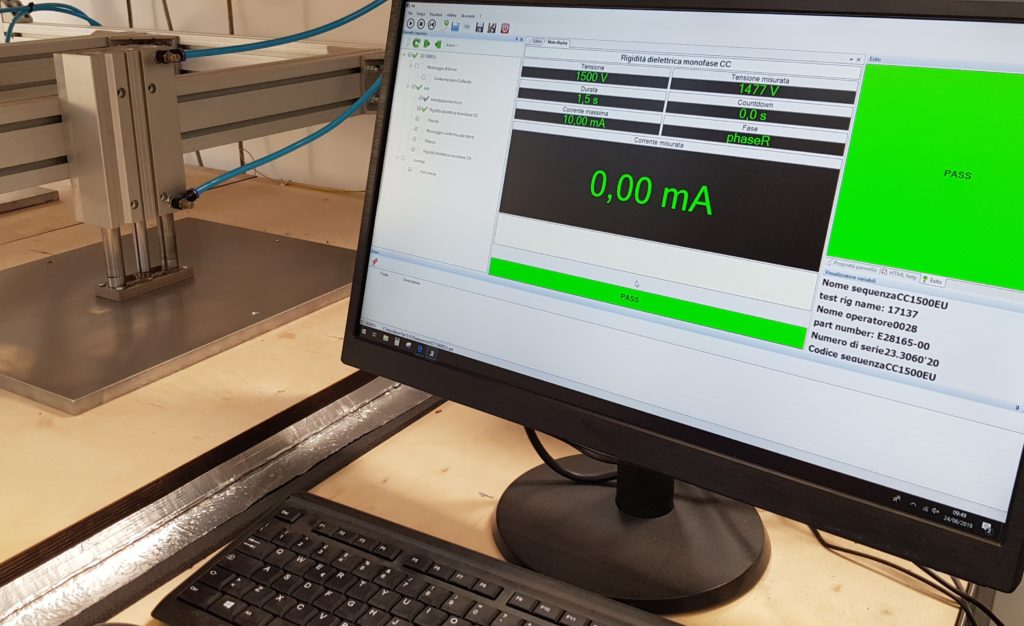

The use of highly thermo-stabilized polyester supports, properly treated for the adhesion of conductive silver and carbon pastes, confers high mechanical resistance and equal reliability in time to Alper heating elements (protected by dielectric films that allow passing the electric rigidity tests exceeding 3,750 V).

«Conductive pastes – specifies Alessi – as well as the conductive and resistive part that generates heat, are in-house studied, formulated and implemented, upon single specification and according to the application. An additive manufacturing technology, instead of subtractive, which then does not use chemical processes. In other words, our processes do not produce noxious industrial wastes, and even less polluting or toxic wastes to be disposed, with an undeniable environmental and ecologic benefit».

The heating element is printed on a very thin and flexible support and therefore it can be positioned in very narrow spaces, adapting it to curve surfaces, too. Various shapes of the element are possible, as it can have also holes or slots for applications needing them.

Worth highlighting that Alper carbon heating elements are made with very ductile conductive pastes, then they always assure great reliability even subjecting the heating circuit to constant movements and bending. Moreover, according to their composition, they allow silk-screen printing resistances that are not constant when the temperature changes but instead increase hand in hand with its rise.

«In practice –Alessi explains– this results in a decrease of the absorbed power proportionally to the high temperature level reached. This feature is very important from many points of view, safety included: resistances of this kind are in fact prearranged to reach the correct thermal balance with the environment».

On demand, Alper can supply a broad range of accessories, like for instance NTC probes, thermocouples, pt100, pt1000, fixed and adjustable thermostats and pockets for probe housing.

«Still for the automotive industry –Alessi adds– we produce also silk-screen printed antennas for the reception of digital radio stations, i.e. DAB, generally integrated in spoilers, in bumpers and wheel arcs of modern cars. Moreover, our ultra-flat carbon resistances are suitable for heating rear-view mirrors, some inner parts of cars, like seats, mats, roof as radiant heating of the car interior, arm rests and so on».

Total 100% quality

ISO 9001 and ISO 45001 certified, since its establishment conceived and organized as structure oriented to the process efficiency and the product quality, Alper has always paid great attention to its development cycle, granted by a skilled team. A group today consisting of twenty workers whose activity exploits advanced managerial systems and software, from design to production, from testing to logistics.

“The manufacturing process – ends Alessi – is constantly managed, coordinated and monitored in each phase, assuring high quality. The operational course provides for a total 100% control and not for a sampling test codification”.

Uncompromised total quality, then, combined with certain production times. All that confers the company great efficiency and precision in deliveries, appreciated by direct and indirect customers, spread worldwide. Concerning this, it is worth underlining that Alper, with the precise target of providing higher and higher level service, for a couple of years now has been able to certify its products also as required by UL regulations for the American market.

The company in brief

Established in 1992 as Research & Development Centre of Carbon conductive pastes with PTC effect, Alper developed, first in the world, a range of polyester heating elements with high power density, which has allowed its customers to be the first entering the USA market with innovative products. Building on the gained know-how, astride 2000s the company starts diversifying its product range. A winning choice that determines a constant growth up to being today, in Italy, a forefront manufacturing reality that produces flexible heating elements, made of polyester and other materials, for the most different applications and markets, with over half million units produced yearly.

A company that still today, in Italy, is unique of its kind, with a proposal of ultra-flat heating elements that allows satisfying the most different technological, productive and qualitative requirements. In addition to the household appliance industry, among the main supplied sectors stand out the general industry, Ho.Re.Ca, building and the rising automotive, for a turnover amounting to about 2.5 million Euros, half of which directly addressed abroad (from Germany to Spain, from England to France), considering that also 80% of the remaining part goes beyond the borders.

A self-ventilating machine

The main product types that will feature in the Parsons Peebles standard product portfolio include the PPD series, an IC411 motor which is a self-ventilating, enclosed machine with external fins and an external shaft mounted fan. The PPT Series is an IC611 motor which is also an enclosed machine and has a built on heat exchanger and shaft mounted fans. The PPC Series, an ICO1 motor, is a self-ventilating machine that is integral fan cooled by a shaft mounted fan. These all conform to the IC code as laid down in 60034-6.

The three-phase squirrel caged induction designs, come in a range of voltages, most commonly 3.3kV, 6.6KV and 11kV with class F insulation and class B rise as standard. The product range covers 2 to 10 poles in sizes up to 560 frame, across a power range of 185kW to 2.8MW.

The introduction of the standard product range to the Parsons Peebles portfolio widens the opportunity of the company offering to many markets including the process industry, cement & aggregates, metals and water and wastewater treatment. Parsons Peebles are already very active in these industries through its acquisitions of service companies, Anstee & Ware and Taylor and Goodman, who have many years of experience in servicing electrical and mechanical machines such as LV/MV/HV motors, pumps, gearboxes and air compressors. The new Parsons Peebles standard product range will be sure to further compliment the business’s offering and support these markets more extensively.

Smooth body motors in a new motor size

Nord Drivesystems offers a wide range of smooth surface motors for industries and applications with high hygiene standards. In order to fully support the requirements of lower power motors, the drive specialist has now developed an additional motor size. The new size 71 smooth body motors are available in three power classes: 0.12 kW, 0.18 kW and 0.25 kW.

IE3 efficiency level guarantees resource-saving operation. Thanks to their aluminium housing (protection class IP66), the motors are protected against corrosion. Additional protection is provided by the optionally available, innovative nsd tupH surface treatment. Nord smooth body motors are fanless and therefore contribute to the non-proliferation of germs during production.

The modular design provides wide application flexibility due to numerous equipment options. Variants with condensation outlets (sealed), encapsulated terminal box, standstill heating, temperature sensor, temperature monitor and/or protection class IP69K expand, among other things, the possible uses. The motors are available in various versions. This way they are suitable for the entire Nord range, preferably for use with Nord aluminium smooth surface drives (Nordbloc.1 helical gear units, Nordbloc.1 bevel gear units, SMI worm gears).

Nord smooth surface motors are specifically designed for easy cleaning and have even and regular surface transitions wherever possible. Thus, cleaning liquids and foam can wash off easily. Due to their washdown design, they are especially suitable for the application in the food and beverage industry.

IE3 energy efficiency starting from 0.09 kW

In Europe, the 640/2009 Regulation on electric asynchronous motors, which has been transposed in more phases, has been in force for some years now. Currently, the regulation concerns 50 Hz or 50Hz/60Hz three-phase asynchronous motors, for constant operation, with nominal powers between 0.75 kW and 375 kW, with 2, 4 and 6 poles; the energy efficiency class for use in net must be minimum IE3 for them.

The new DRN motors constitute integral part of our modular system of motors. A new interface with mechanical reducer, able to assure higher flexibility and system combination. With optimized weight, sizes and efficiency, these asynchronous motors can be easily integrated into machines and plants for high energy-efficiency operation. The new IE3 motors are naturally compliant with all main global specifications and design regulations like IEC 60034, NEMA MG1, UL 1004-1, CSA C22.2-100, ABNT 17094-1 and GB 12350 (CCC). Moreover, they already conform to the next regulations in the energy efficiency field for Europe, India, Brazil, USA, Canada, China and other Countries.

All this makes Sew-Eurodrive an outstanding manufacturer of low energy consumption gearmotors of the IE3 efficiency class, with nominal powers included between 90 and 200 watts, with all customary quality and a complete line of services connected with the product that operators know and appreciate.

Electric motor: what is the real innovation?

What are the structural choices that make a motor innovative and super-performing? What are the most suitable materials for obtaining the best of each component in the design layout?

We have asked it to a great expert: Luca Ianni, Engineer and Electric Motor Specialist of AVL, among the leader forefront companies, which at its sites, including the Italian hub at Cavriago (RE), is intercepting and outlining the present and the future of the electric motor of excellence.

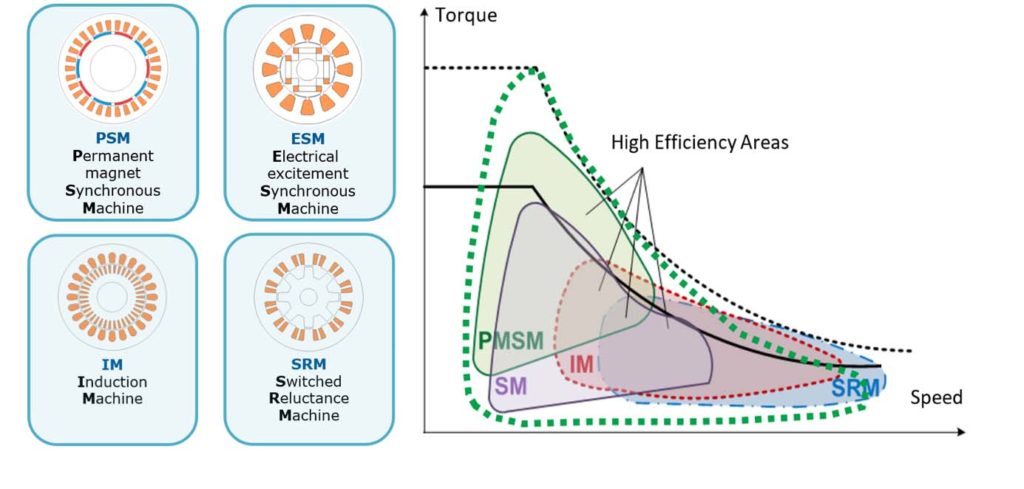

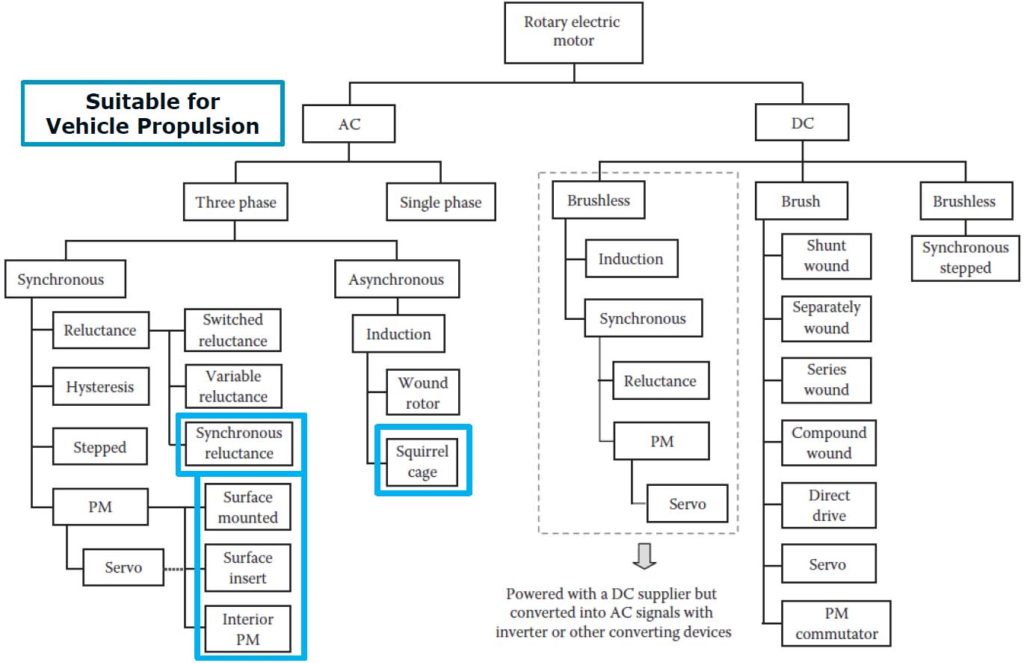

Before going into the impressive theme that highlights the innovation of electric motors, with the target of exceeding the limit of the performances reached today from the point of view of technology and electromagnetic operation, especially in automotive ambit, it is necessary to do a macro-subdivision of electric motors; first between those with axial flux and radial flux. «In the automotive sector, we still find both motor typologies, even if there is growing interest in axial flux motors due to the achievable torque and power density performances. Today the axial flux motor can reach levels that were unconceivable last years, especially in terms of cost, because this motor typology features higher manufacturing difficulties that made the manufacturing cost rise and then induced to discard it a priori, owing to budgets, compared with radial flux motors».

Other macro-divisions among motors see on one hand permanent magnets synchronous motors, then brushless motors that in their turn can be split into surface mounted permanent magnet motors and internal permanent magnet motors, the latter called also IPM, widely used in the automotive industry because they allow exploiting the reluctance torque component, increasing efficiency and extending the speed range versus other structural typologies. On the other hand, there are wound rotor synchronous motors without magnets in their interior but with windings in the rotor, too. Asynchronous motors with squirrel cage rotor, appreciated for their low costs, high operation temperatures and the user-friendliness of the drive control. Finally, reluctance motors, which exploit only the reluctance contribution to produce torque, characterized by a simple rotor, without windings, bars or magnets, and then easily manufactured, not expensive and mechanically sturdy.

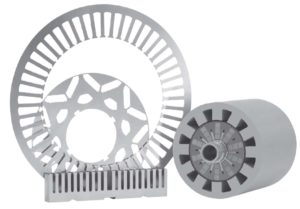

Laminations

Beyond the simulation and design aspect that allows attaining more performing motors than in the past, what makes an electric motor become innovative, in comparison with past decades, is undoubtedly the choice of materials. In this context, a fundamental role is played by the lamination composing the rotor and the stator.

wire EDM cutting

«Today we more and more often use laminations of iron –cobalt material, characterized by better performances in the electromagnetic behaviour, broader use range before saturation and low loss figures, with unchanged induction and frequencies, compared to other materials like iron-silicon. On the other hand, iron-cobalt features lower yield stress values than iron-silicon and therefore, for high-speed applications with notable mechanical stresses, the design optimization (i.e. flux barriers for IPM motors) and manufacturing techniques, like for instance backlack, become crucial. Iron losses are also reduced by the strong rolling of stator and rotor stacks: the more we decrease the thickness of these laminations, the more we reduce eddy-effect losses The trend that is prevailing today is having laminations around 0.2mm, even if with current cutting techniques we can obtain laminations of just 55µm. Obviously, 0.2mm laminations can be easily processed with punching and laser cutting techniques and then suitable for mass-production, on the contrary, from 55µm laminations we can achieve the wished geometries only through “Wire EDM” cutting techniques, suiting small volumes».

Magnets

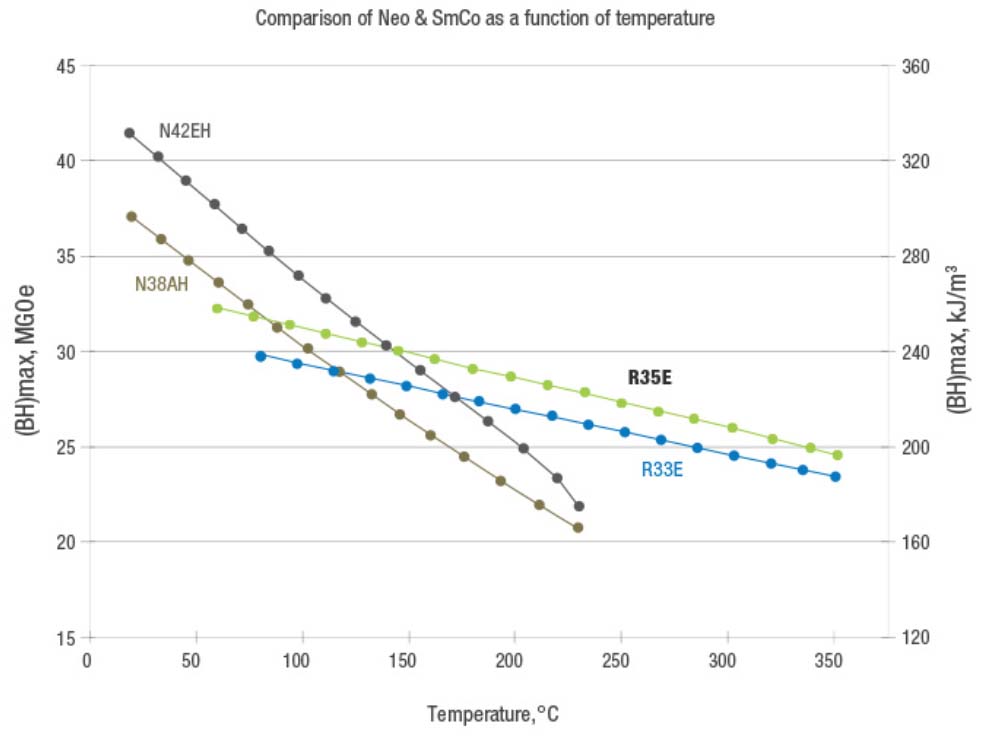

Throughout the years, the performances of the magnets offered by suppliers constantly improve. On the market, in fact, are available products with higher values of remanence and intrinsic coercitivity than in the past, this results in higher performance with the same magnet volumes and minor demagnetization problems, with the advantage of motors that can operate at higher temperatures and with higher inner magnetic fluxes, then improved torque and power density performances.

«Speaking of the materials that compose magnets, typically in the industrial sector but also in the automotive, Neodymium-Iron -Boron (NdFeB) is broadly used.

Other magnet typology is Samarium-Cobalt (SmCo) one that, even if more expensive, has higher BHmax values than NdFeB ones for temperatures exceeding about 150/180°C, but lower values compared to the best grades of NdFeB for lower temperatures.

The SmCo magnet features then higher remanence values at high temperatures and is less affected by demagnetization problems, featuring higher intrinsic coercitivity values than other typologies. In the choice of one instead of the other, we must understand what performance target we want to reach and then the thermal class of the motor. If we decide designing a motor that operates at 200°C and over (C thermal class), SmCo magnets certainly assure better performances. Moreover, the high admissible thermal delta, with regard to the environmental temperature, allows increasing torque and power densities of the motor at unreachable values with NdFeB magnets used at lower temperatures (F or H thermal classes)».

Windings

Another variant that is increasingly present in current motors is given by a growing use of hairpins instead of wire windings that constitute the wound stator. «We are witnessing a growing use, especially in the automotive industry, of hairpins, then enameled copper bars used to form windings inside stator slots. Benefits are immediate thanks to the bigger quantity of conductive material that can be inserted into the slots, leaving fewer empty spaces among conductors and then improving also the heat dissipation capacity».

The fill factor, then the ratio between copper area and slot area, generally reaches values ranging from 0.3 to 0.6 by using copper wires; with the use of hairpins and with an optimized slot geometry for the specific conductor, it is possible to go beyond this limit. Increasing the fill factor, then having more copper at disposal inside the slot itself, with unchanged current allows reducing joule losses, and therefore improving efficiency and reducing over-temperatures; reasoning instead with the same admissible thermal delta, it means the possibility of improving motor performances and then the torque density, with the same mass and volume.

Moreover, hairpins can be rolled in such a way as to avoid skin effect phenomena in the conductor.

Heat dissipation

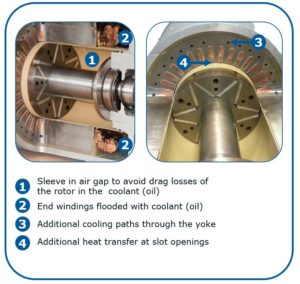

The heat generation is connected with losses that occur inside the motor, they can be either joule losses in stator windings, or in rotor bars for induction motors, eddy effect and hysteresis losses in the laminations of rotor and stator, eddy effect losses in magnets, friction losses in bearings and windage losses in the magnetic gap in air between stator and rotor.

«All these losses result in heat generation; improving the cooling system and then the capability of extracting this heat from the motor and of dissipating it allows making the motor more performing: the better we dissipate heat, the higher performances will be».

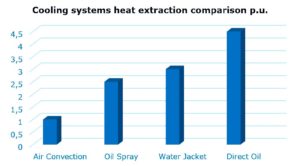

There are different modalities to dissipate heat and each way has different efficaciousness. In industrial ambit, we generally opt for cooling through natural convection, broadly used for brushless motors or for air-forced systems often used in asynchronous with winged enclosures; we make the air flow (moved by a fan connected with the shaft or driven by a secondary motor) on the outer enclosure of the motor, increasing the thermal exchange that would occur with the standard convection. However, the performances we can obtain from these systems are distant from the ones wished for high power density motors. To grant better performances it is necessary to choose other methods, especially for the automotive sector of sport cars, where the research of performances is fundamental.

A more performing system provides for the use of a water jacket that forms the motor enclosure, containing ducts where the coolant flows, generally a water and glycol mixture. This broadly used typology allows attaining 3-time higher heat extraction than in a motor cooled by natural convection only.

A more performing system provides for the use of a water jacket that forms the motor enclosure, containing ducts where the coolant flows, generally a water and glycol mixture. This broadly used typology allows attaining 3-time higher heat extraction than in a motor cooled by natural convection only.

A result resembling this cooling solution is achievable through the oil spray system, i.e. the injection of refrigerated oil on the heads of stator windings, therefore directly permitting to extract heat from the copper section protruding from the stator stack.

«There is another method, more performing than all others but less used, which allows a 4.5 time higher heat dissipation than natural convection: the complete immersion of the stator inside the oil that implies an excellent heat extraction from the stator and relative windings. Currently, despite the positive results, it is not largely used because this method requires particular manufacturing devices and this means that also costs increase hand in hand with performances, rise that cannot be justified for some applications».

The integration of the perfect mix

The perfect mix of components for the best possible motor? «A motor able to encompass the best of all materials and optimal electromagnetic, thermal and mechanical design, combined with all aspects of NVH and component noise optimization. Therefore, today the identikit of the innovative motor might be a brushless internal permanent magnet motor made of samarium-cobalt, which admit a use at steady-state temperatures exceeding 180°C, possibly in C class, with direct cooling in oil; iron-cobalt laminations in backlack, researching speeds certainly surpassing 20.000rpm with reduced losses. We should not underestimate the importance of having insulating material, resins and pottings, able to withstand temperatures exceeding 200°C, for the consequent freedom of a less constrained design, able to provide higher and higher performances. The potting compounds, for instance, used to encapsulate windings, which give benefits not only in terms of electric insulation but also in the heat exchange between windings and laminations, are today limited to temperatures inferior to the C class; besides, for all those applications that provide also for a particular motor certification for the sale in some States, like UL for the United States and CSA for Canada, the thermal limit of the insulating material is fixed at much lower values than the real limit of the component, then making the pursuit of the absolute performance, and at the same time the certification of the motor for a certain market, almost impossible».

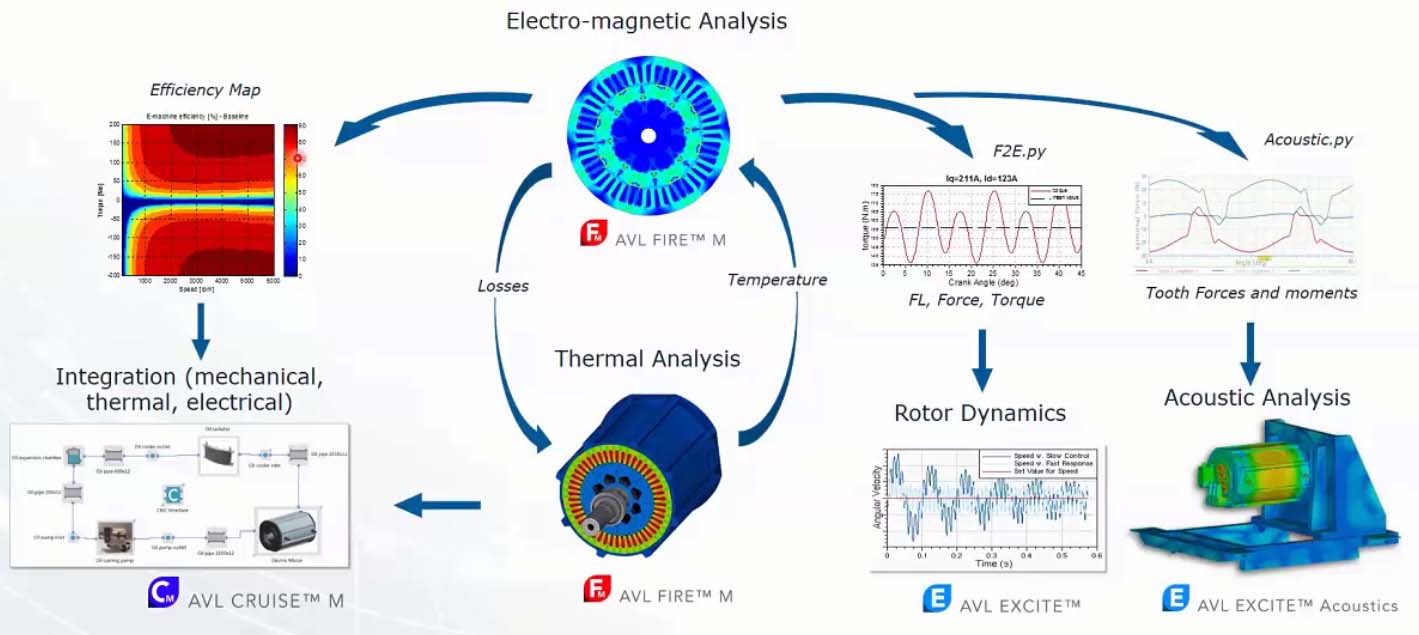

The motor performance is strictly linked with design and simulations carried out before the prototyping and production phases are fundamental. In a first step, it is possible to use 1D concentrated parameter calculation software for both the preliminary sizing and thermal simulations. In a second phase of more accurate optimization, FEM and CFD finite element simulation software, both 2D and 3D, are used, thus covering all the aspects that characterize an electric motor, from the electromagnetic circuit to mechanical, thermal and NVH performance, up to the study of the behaviour that occurs when the motor operates inside the application system, such as for instance an electric axle or an entire powertrain. «A study of this kind, then more in-depth, with more accurate simulations, addresses for instance the automotive ambit because torque and power densities of the motors intended for the most performing cars, are at the limit of technical possibilities, especially for high-speed applications or wherever we try to optimize efficiency at best or to exploit as much as possible the admissible thermal jump from used materials.

Besides the simulations, there is a key step: the test on the manufactured motor. It is not sufficient, in fact, to design and to simulate it, it is necessary to be able to test it accurately once manufactured, especially concerning the first prototypes, in order to validate the simulations executed; collecting precise data on prototypes allows carrying out the due optimizations in the second phase of simulations; besides, it is possible to acquire the necessary inputs for other simulation typologies, hardly executable without a first test phase, like for instance the airborne simulations for the definition and the reduction of noises».

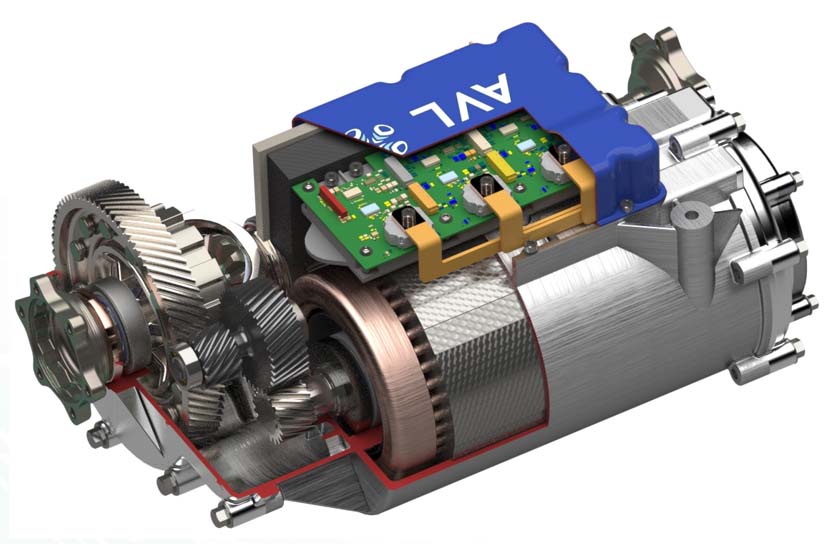

The excellence of AVL deserves to be highlighted not only due to the capability of designing highly performing motors but also for the ability of integrating them at best inside use systems, to the ends of real innovation that provides for the integration of the electric motor with power electronics and mechanical transmission.

«What we are developing as AVL is an integrated design package, where the whole motor enclosure is devised for its connection with the inverter and the gearbox. All that allows achieving a noteworthy reduction of sizes and weights and then making the real difference in some applications, such as the automotive ambit».

WEG Motor Scan is an Industry 4.0 solution

WEG Motor Scan is a device that enables periodical monitoring on electric motors. Technologically designed, mainly for maintenance purposes, the device can monitor reliability of electric motors installed on an application in order to ensure process efficiency and avoid downtime risk.

In terms of operation, the WEG Motor Scan allows users to monitor motor performance through a smart device (the App is available for Android and iOS) and a web platform (WEG IoT Platform). Based on collected data and then sent to the cloud, faster and more accurate decisions may be taken, specially in cases of predicted maintenance, ensuring higher efficiency and extended motor life time.

In addition, there is the possibility of setting up the sensor to trigger alerts based on collected and stored data and in order to make the monitoring of several motors easier in the factory, it is possible to monitor all motors fitted with WEG Motor Scan on the same screen of the WEG IoT Platform.

Among other benefits offered by this solution is the optimization of maintenance routine, reduction of replacement parts, increase of electric motor life time and energy efficiency improvement.

«WEG is in line with the fast changing market trends focusing its best efforts on technology development for Industry 4.0. This initiative brings major benefits to customers at a reasonable cost» – says Milton Castella, Engineering Director of Motors and Energy Divisions. According to Milton, this solution will show exactly how the IoT concept can be turned into reality and bring benefits for a wide variety of industrial sectors.

Energy saving IE4 synchronous motors

To optimise the total cost of ownership, Nord Drivesystems supplies drive solutions to reduce operating costs. This includes reduction of the number of versions with the aid of the Nord modular system, reduction of energy consumption through the use of efficient IE4 synchronous motors, long service life and low maintenance Nord drive units. Energy saving IE4 synchronous motors from Nord are highly efficient and meet the most stringent energy regulations – and thanks to Pmsm technology, also in the partial load and speed ranges. This enables significant cost savings. In addition, Nord systems facilitate reduction of the number of versions and spare parts management. For Intralogistics and airport applications, Nord supplies the LogiDrive standardised geared motor system consisting of an IE4 synchronous motor, a two-stage bevel gear unit and a Nordac Link field distributor is a perfectly matched drive system. For pallet conveying technology Nord offers an economical combination of an asynchronous motor and the Nordac Base frequency inverter.

The high quality and reliability of Nord Products results in a longer service life with lower maintenance costs, which further reduces the total cost.

Also, with the aid of Nord frequency inverters, maintenance and repair costs can be significantly reduced and plant availability increased.

WEG, preventive and predictive maintenance

Released on the market by WEG, the device enables electric motors to play a protagonist role in the Industry 4.0 ambit. A technological solution that allows minimizing, or even eliminating, machine downtimes and remarkably improving the manufacturing process efficiency.

Gianandrea Mazzola

Motors are always subjected to strong stresses and long operation hours and it is unavoidable they are affected by a certain wear level. However, they unfrequently break down without warning. Usually, the signs of an imminent failure are anticipated by an increase of vibrations and by the high temperature. Parameters that, if not controlled and supervised carefully, can lead to unexpected stops, plant downtimes and therefore undesired financial losses. Consequently, the constant monitoring of vibrations, of temperature and of operation time becomes decisive as well as necessary to the ends of higher competitive edge. The timely warning of potential problems allows in fact executing the due maintenance and repair interventions, thus avoiding unscheduled interruptions. Definitively, a constant monitoring can increase productivity, improve quality and rise profits. Precisely in this context, WEG, one of the major world manufacturers of cutting-edge motors and drives, presented Motor Scan.

«We are referring to a user-friendly and effective device – explains Fabrizio Arosio, automation business manager of WEG Italia – that allows the remote monitoring of WEG motors, in order to maximise the use time and to permit both preventive and predictive maintenance activities». This technology allows in fact maintenance technicians to take informed decisions about the «health state» of installed motors and to react consequently, according to the acquired data.

From the motor to the IIoT, from Big Data to higher competitive edge

Available for frame sizes from 100 to 450, the device by WEG grants immediate usability. It exploits the Industry 4.0 digital technology, which includes Industrial Internet of Things (IIoT) and Big Data Analytics to offer its customers a competitive edge in this dynamic and complex activity sector. Due to its devising and development, the device aims at avoiding the boring manual collection and monitoring of data, at removing the conjectures about preventive maintenance and at eliminating the inefficiency of the reactive maintenance.

«Motor Scan – adds Arosio – can predict and highlight a problem before it occurs. In a certain sense, it is as if we had a sort of crystal ball that allows knowing what will happen in the future. We believe that, preventing a problem before it occurs is the attainment of the best efficiency in terms of cost and maintenance. The device exploits the IIoT and the analysis to connect sensors and other devices aimed at collecting and analysing data in real time and besides it offers transparency in the adoption of immediate preventive actions. Moreover, our new solution helps customers in increasing the safety of their plants, remaining anyway competitive in this demanding constantly evolving sector». The sensor can be easily installed (even in a time following the motor installation) through a clamp and today it can detect vibrations, surface temperature, operation hours, speed and start/stop through a Bluetooth connection. For practical reasons, the collected data are stored in the cloud and users can exploit an available app for both iOS and Android, on their smartphones or tablets, to gain access to it. Besides, the access to data on laptop and desktop is enabled by a dedicated Web portal. A powerful analysis system allows processing data and anticipating possible hidden anomalies or problems according to the analysis of the frequency spectrum. Various warning levels, according to acceptable reference values of temperature/vibration, are pre-set, with the possibility of tracing performance curves on the basis of the collected data.

The added-value of a correct sizing

«Actually – adds Arosio – simultaneously with the installation, through the input of the univocal identification code of the single motor, the device automatically recognizes dozens and dozens of further product information, from the number of coils to their type of winding. Data that, through apposite algorithms, in the future will also enable, besides other things, to control the frequency, the efficiency and the real absorption in real time of the motor».

Moreover, these data will permit to check the correct motor sizing depending on the specific application. With noteworthy saving benefits.

«In fact, it quite often happens – further highlights Arosio – that starting from the designer’s initial sizing, to comply with the regulatory tolerances and so on, you achieve a motor used not by 100% but with much lower efficiencies. In other words, motors might be oversized or also undersized with respect to the load they are intended for. Discrepancy that unavoidably leads to some inefficiencies».

An oversized motor consumes more electric energy owing to a low power factor that increases costs. On the other hand, an undersized motor causes overheating. Therefore, it is important to monitor the motor load and to match the motor with its effective requirements, in order to improve the system performances and generate cost saving. For a certain number of years, in fact, the achievement of the energy efficiency has been the key target of industry. However, there is a concrete problem concerning the motor-load correspondence. Some energy savings must be obtained through the «right sizing». For this reason, the future evolution of Motor Scan will include the motor measuring.

Stop to vibrations, high temperatures and possible degradations of components

As already mentioned, the rise of vibrations, the high temperature and prolonged operation time of the motor can generate some risks, with undesired effects on the process where it is used. More in detail, anomalous vibrations come from electric or mechanical unbalances inside the motor. The electric causes include the variation of the flow around the stator that produces a variation of forces between the stator and the rotor, a broken rotor bar or a short circuit that involves a part of the winding. Mechanical causes include instead an unsuitable motor base and defective bearings.

«The complications caused by vibrations – points out Arosio – can for instance accelerate the bearing yielding, resulting in recesses on the tracks at the distance between balls or rollers».

Concerning temperature, some components, especially mobile parts, tend to release unusual heat quantities when they degrade. The presence of excessive heat can indicate an excess of friction, i.e. the presence of misalignments of components that rub one against the other (and they should not).

«According to some studies carried out – underlines Arosio – they estimate that each 10° rise of the operation temperature of motor windings, compared to the setup temperature, corresponds to the 50% reduction of the insulation duration of motor windings, even if the overheating is only temporary».

The effects of a protracted operation time can finally affect the fast degradation of some motor components. This occurs owing to the accumulation of overheating and stresses.

«To prolong the motor service life – notices Arosio – it is decisive, as well as important, monitoring the operation time and ascertaining that an excessive use is avoided. Moreover, the monitoring can offer the opportunity of an energy saving, permitting to switch motors off when they are not in use».

Reducing the motor operation time by just 10%, you achieve an energy saving that exceeds the one achievable by replacing a standard efficiency one with a high-efficiency execution. In short, the effective Motor Scan device not only allows eliminating the monotonous manual collection and monitoring of data but also makes preventive maintenance suppositions superfluous and actually annuls the inefficiency of the reactive maintenance. Besides, training maintenance technicians according to the particular requisites of predictive maintenance, it offers companies the opportunity of developing the staff’s skills, widening their capabilities and competences.

Axalta A new epoxy resin Voltacast 3310

Axalta, a global supplier of liquid and powder coatings, launches Voltacast 3310/Voltacast H134, a new epoxy-based casting resin system that expands the Voltacast product portfolio of casting resins from Axalta’s Energy Solutions business.

Voltacast 3310 is specifically designed to offer high thermal stability in combination with high thermal conductivity for winding head encapsulation or total stator encapsulation of electric motors, like servo drives or large machine tools.

“We are always looking to expand our product portfolios and to meet the ever-evolving needs of our customers,” explains Christoph Lomoschitz, Global Product Manager for Axalta’s Energy Solutions business. “Voltacast 3310 ensures outstanding resistance to a variety of automatic transmission fluid oils used in electric vehicles, and its high thermal conductivity in combination with oil cooling of electric motors allows maximum heat dissipation.”

Voltacast 3310/Voltacast H134’s anhydride-free system can be cured at room temperature or preferably at temperatures up to 70ºC. The cured material is flame retardant, fulfilling the requirements of Underwriters Laboratories (UL) standard 94, class V0, and will shortly receive official UL recognition.

The new Voltacast 3300 range is comprised of two-component systems – an epoxy resin and a hardener. The products of the Voltacast 3300 range offer superior thermal conductivity, from 1.2 W/mK up to 1.6 W/mK, without compromising an easy and safe application, as the processing viscosities are only 2200 mPa*s to 2400mPa*s at room temperature. The new Voltacast materials are very versatile, with glass transition temperatures of 24ºC, 60ºC and 95ºC, depending on the final application requirements.

The new Voltacast 3300 range is comprised of two-component systems – an epoxy resin and a hardener. The products of the Voltacast 3300 range offer superior thermal conductivity, from 1.2 W/mK up to 1.6 W/mK, without compromising an easy and safe application, as the processing viscosities are only 2200 mPa*s to 2400mPa*s at room temperature. The new Voltacast materials are very versatile, with glass transition temperatures of 24ºC, 60ºC and 95ºC, depending on the final application requirements.