The first 7.5-ton electric trucks by the British company Tevva, mass-produced, started being delivered to customers including Expect Distribution, Travis Perkins and Royal Mail. The enterprise, become the first company in UK that has received the EC Whole Vehicle Type approval for an electric 7.5-t truck, expects to sell up to 1,000 electric trucks in 2023. To receive the approval of the whole vehicle, Tevva truck has been subjected to 30 systems tests, including the electric safety and the electromagnetic compatibility according to latest standards.

The truck allows an autonomy up to 227 km due to its 105 kWh battery charge.

Tevva Founder and CEO Asher Bennett said: «We continue to “charge on” as a company and reach new milestones, with type approval being the latest and most important landmark we’ve achieved to date. I am incredibly proud of our team who have worked tirelessly to secure this certification and get our 7.5t electric truck in customers’ hands and on the roads. We are on a mission to make sustainable trucks accessible at scale and believe our technology will empower the transport sector and the governments of Europe to meet their net-zero goals. By embracing both hydrogen and electric fuel sources, we can rethink the energy mix in transport, reduce strain on our electricity grid and accelerate electric truck adoption».

Tevva electric truck is close to the mass production

EuroGroup Laminations listed on the main list of Italian Stock Exchange

Active in the design, manufacturing and distribution of stators and rotors for electric motors and generators and operating with the specific business units EV & Automotive and Industrial, EuroGroup Laminations is protagonist of the fourth listing on Euronext in 2023 and of the first admission since the beginning of the year on Euronext Milan, bringing to figure 224 the number of the companies currently listed on this market.

Moreover, it is the fifth company admitted on Euronext Tech Leaders since the launch of the initiative in June 2022, raising to 112 the total number of Euronext Tech Leaders companies.

The company has overall collected €432 millions and therefore its growth course is running. Here are the words by Marco Arduini, CEO of EuroGroup Laminations spa «The listing on the primary list of Italian Stock Exchange constitutes for us the umpteenth stage of a growth course started 56 years ago and in constant evolution. Passion, vision, innovation and market interpretation skills are just some of the ingredients that have allowed us to reach important achievements and to gain the world leadership in our sector. A thankful thought is dedicated to the 2800 EGLA collaborators who every day contribute in its performance and in its development. We are a united motivated team! I am convinced that together we will be able to reciprocate the trust of the numerous prestigious investors who have believed in us. We will invest the collected resources in a further course of sound growth and of sustainable value creation in the medium-long term. The ranking and the visibility that derive from the “status” of listed company will permit us to seize new business opportunities to pursue the ambitious and challenging targets we have issued for the future».

Batteries with 3D Printing? Here is the success of Sakuu

We are overcoming new frontiers in the printing of fully functional batteries in custom shapes and sizes with patterned openings for thermal management in a fully dry process.

Concerning this, market protagonists include the pioneering additive manufacturing company Sakuu, on-track for commercial-scale production of printed batteries in major industries including E-mobility, aerospace, EVs, grid energy storage, and more.

The company is inventor of the disruptive Kavian™ platform solution for the commercial-scale production of next-generation SwiftPrint™ batteries and other complex active devices, announces that since December 2022 it has successfully and consistently 3D printed fully functional performant batteries in custom shapes and sizes. These batteries were printed as patterned cells containing patterned openings for thermal management, in a fully dry process, at Sakuu’s Silicon Valley battery pilot line facility.

This marks a first-of-its-kind recorded manufacturing achievement and is an important step towards Sakuu’s planned commercial-scale production of next-generation SwiftPrint™ batteries, including solid-state batteries, from its Kavian™ platform in gigafactories worldwide.

Karl Littau, Chief Technology Officer at Sakuu commented: «Our development shows that the Kavian™ platform can enable commercial-scale, sustainable production of a wide range of battery technologies from lithium-ion to lithium metal to even solid-state batteries—whereas traditional methods of advanced cell manufacturing continually run into core impediments that prevent mass-scale production. Further, our printing process can allow for substantial gains in energy density for a completed battery. Finally, our platform can customize the form factor of the battery—whereby the battery itself can become part of product design via customized shapes and sizes. This is a profound moment with enormous implications for advanced battery manufacturing».

The witness by Robert Bagherim, Sakuu Founder and CEO is instead the following: «Printing custom patterned batteries using a dry process that starts with raw material and concludes with a fully functional high-performance battery is a breakthrough that has the potential to transform how batteries of the future are manufactured for all industries. This milestone advances integration between our Kavian platform and our commercial-scale battery production plans towards an energy output goal of 200GWh by 2030 via a network of global partner gigafactories».

Ancma data: electric two-wheelers are decreasing

After the excellent year start, the data recently diffused by Confindustria Ancma (National Association of Cycle Motorcycle Accessories) on the February Italian market of bikes, scooters and motorcycles describe an overall +20.9% versus the same 2022-month, but certainly with not enthusiastic news for electric two-wheelers.

In fact, the electric market does not take off during 2023, closing February with 838 units, with a 3.23% downturn versus the same 2022-month. In the first bimonthly, electric drops by 10.82% versus 2022 and makes 1,706 zero-emission vehicles circulate on the road. However, it is necessary to highlight that the first two months of 2022 had scored the 82% rise.

The president of Ancma, Paolo Magri, has highlighted how «the solution of many of residual provisioning problems allows the market to express its potential at best, still confirming our products’ central role as possible enjoyable choice for individual displacements and for the uses more connected with passion, with tourism and sport. For this reason, we think that local administrations’ political agenda must consider, in the debate about the sustainability of transports and cities’ future, the determinant contribution that motorcycles go on offering to the solution of mobility problems». Are incentives in the direction of zero emissions hoped for?

2035 and the automotive chain: changing the manufacturing model to meet a technological transformation

On Thursday, March 29th, starting from 2.30 p.m., at the Arena of Bologna Trade Fair Service Centre, inside the MECSPE Exhibition Core, it will be held the Italian-German Forum dedicated to the automotive industry and to the great changes the latter will be called to face within 2035.

The issues will concern frame parts that shall be reengineered with new solutions, innovative and lighter materials that will replace steel, a stronger presence of on-board electronics, the whole power line that will need to be reconceived, control and management of the powertrain that will gain more and more importance, but we will also talk about the new character that supply chains will be expected to acquire.

Experts in technologies and market, through successful best practices and case histories, in collaboration with the Italian-German Chamber of Commerce, the division of industrial exhibitions of Stuttgart Trade Fair, including AMB and Moulding Expo, and Tecniche Nuove Group, will create an afternoon full of ideas and insights, analysing the challenges the automotive industry is called to face, the possible impact of the sustainable mobility on the supply chain and the adoptable measures.

Italian-German Forum:2035 and the automotive chain: changing the manufacturing model to meet a technological transformation

The programme of the Forum coordinated by Alessandro Garnero, editorial director of Tecniche Nuove Group, will be divided into three moments of debate and discussion:

• 2.30 – 3.30 p.m. Plenary session: The automotive scenario in constant evolution.

Moderator of the session will be Alessandro Marino, Secretary General of the Italian-German Chamber of Commerce.

Speeches will be delivered by prof. Karsten Stahl, Director of the Polytechnics and of FZG Institute in Munich; Markus Heseding, Director of the German Precision Tool Association (VDMA); prof. Ciro Attaianese, Director of ELMO Electrification of Mobility Inter-university Consortium and Dino Calia, manager of RD/BDQ Joint Battery – Supplier Quality & Project Safeguarding of Mercedes-Benz AG; Prof. Nicola Amati, Turin Polytechnics.

• 3.30 – 4.30 p.m. Panel 1: The impact of electromobility on the automotive chain and the response of Italy and Germany.

Moderator of the session will be prof. Carlo Gorla of Milan Polytechnics.

The floor will be given to the German and Italian industries of the subcontracting chain. In particular, Claudio Mus, Endurance Overseas; Davor Petrović, Marzocchi Pompe; Mauro Barchiesi, Bora Italia; Jorge Bertsos, Ubiemme Gühring Italia; Claudio Gabos, Mapal Italia; Prof. Lorella Ceschini, UniBS; Enio Gritti, OMR Automotive; Francesco Meroni, KEB e-mobility; Andrea Loi ZF, Paolo Basilico, KraussMaffei Group Italia.

• 4.30 – 5.30 p.m. Panel 2: The measures worth adopting to facilitate the reshoring and the shortening of supply chains, from design to strategic components.

Moderator of the session will be Mr Stefano Colletta, technical director of Meccanica News Journal.

Institutions’ role for the strengthening of the European industry. The collaboration with innovation and technological transfer centres, the new structure of supply chains.

This session will be attended by: Christoph Gelzer, Project Coordinator of Cars 2.0 Cluster Automotive Region Stuttgart; Federico Capucci, Cluster Manager of Clust-ER MECH Mechatronics and Motoristics; Marco Stella, President of ANFIA Components Group and Vicepresident of ANFIA (The Italian Association of the Automotive Industry); Michele Merola, President AIDAM – Italian Association of Automation and Mechatronics; Roberto Frassine, President Assocompositi and President EuCIA (European Composites Industry Association); Marco Gazzaniga, Business development Icona Design Group.

Electronics and mechanics for future mobility. Electric motor: smaller size for better performance

The international platform of technical information Electric Motor Engineering and the publishing house Tecniche Nuove, in collaboration with Professor Marco Villani, professor of Electrical Machines Design and Electric Systems for Mobility at the University of L’Aquila, on February 28th 2023, from 10.00 a.m. (CET) to 12 a.m. (CET) organize a webinar on the issue of “Electronics and mechanics for future mobility. Electric motor: smaller size for better performance“.

The topics

The entire automotive supply chain will have to readjust its production model to go along with an irreversible transformation. The entire power line will have to be rethought; smaller and lighter electric motors will have to ensure high performance and reliability.

Everything needs to be reengineered by pursuing new solutions; on-board electronics, control and powertrain management will be increasingly important.

Take part to the event organized by the magazine Electric Motor Engineering:

ELECTRONICS AND MECHANICS FOR FUTURE MOBILITY.

ELECTRIC MOTOR: SMALLER SIZE FOR BETTER PERFORMANCE

Webinar – February 28th 2023

from 10.00 a.m. (CET) to 12 a.m. (CET),

Moderator: Prof. Marco Villani, department of Industrial and Information Engineering and Economics University of L’Aquila (Italy)

- Effects of glue bonding in mechanical and magnetic properties of electric motor cores, Mario Villalon – EuroGroup

- Electric motors, winding solutions, Fabrizio Bardelli – CAME

- Electric motors potting with high performance resin systems, Pietro Colombotto e Alberto Menozzi – Demak Group

- Mechanical Face Seals for eMobility: eAxle, Gear Box and ePump, Alessandro Ventura – Meccanotecnica Umbra

- The challenges of automotive electrification for 2-tier suppliers, Cristiano Bora – Bora

In collaboration with

European manufacturing of EV, a new coating line by BMW

To understand the market’s direction, the most truthful litmus test are the manufacturing programmes by the various factories. E BMW clearly shows it, developing and activating in its German Leipzig plant the first coating line of the cells that make up the batteries of BMW Group’s electric cars.

The factory at stake is in constant evolution for the production of components for electric cars and in the future its surface is expected to reach 150,000 square metres, implementing staff to overcome one thousand workers.

The manufacturing capacity of the new coating line amounts to 10 million cells/yearly, that is to say 2,300 cells/or and in 2024 the two existing lines will be joined by a third module assembling line. The production of high-voltage batteries in BMW site in Leipzig is made up by three automated phases: cell coating, production of modules and assembling of batteries.

The next milestone? In Leipzig they will start the production of the new Mini Countryman that in the full electric version will be equipped with “made in Leipzig” batteries.

In the photo battery cell coating at BMW Group Plant Leipzig. Uncoated cells are separated and their positions are checked.

Stellantis-Terrafame, towards a European cluster of batteries

The Finnish Terrafame will supply Stellantis with nickel sulphate for the production of electric vehicles’ batteries. This is a recent agreement signed by the two new partners and framed in the aggressive electrification strategy by Stellantis, which will allow satisfying a significant part of the requirements of sustainable nickel produced in the region.

Carlos Tavares, CEO of Stellantis stated: «This agreement is part of the provisioning strategy of essential raw materials to satisfy our requirements in the production of battery packs for electric vehicles. We go on implementing a new global value chain together with leader partners, to support our global strategy and to prosecute our commitment to becoming the reference sector reality in the contrast to the climatic change, with the target of zeroing net emissions by 2038, in advance versus competitors».

The words by Terrafame, pronounced by the CEO Joni Lukkaroinen are as enthusiastic: «The collaboration with sector leaders such as Stellantis strengthens the ranking of Terrafame as outstanding partner for the supply of chemical components for batteries for the European automotive industry».

Anyway, what about Terrafame? In Finland, it manages one of the largest chemical plants for batteries on a global scale. With an integrated manufacturing process that starts from its mine and ends with the chemical components for batteries in a single industrial site, the production of Terrafame is fully traceable. Moreover, due to the exclusive production technology, the carbon emissions of the nickel sulphate produced by Terrafame are among the lowest in the sector.

Electric cars’ lists, in Italy the position of Stellantis is confirmed

Stellantis press office has recently announced that Fiat started 2023 at the top of the market of 100% electric cars, with a 16.6% market share, growing by 1.6 percentage points compared to January 2022.

Fiat Nuova 500 reconfirms to be the best-selling 100% electric model in Italy in January, with a 16.3% share. Peugeot, with e-208, maintains its primacy in the B sedan segment, with over 50% of share and Peugeot e-2008 is top in the segment of compact SUV.

In the market of low-emission vehicles, Stellantis, with 30% of share, confirms the top ranking also in this first month of the year. The new DS4, in slightly more than one year of life, has succeeded in gaining the second place of the podium among hybrid “plugged” sedans of the C segment with the 18% share, and the growth is constant for Citroën with Plug in Hybrid models, with C5 Aircross that doubles its volumes compared to last year and C5 X that ranks second among the sedans in the D-segment.

Moreover, Stellantis has communicated they rank first in the market of 100% electric commercial vehicles with the 44.7% share, with Fiat brand at the first place and Opel brand at the third in the ranking of the brands of this category in January.

These results represent a further step forward in the execution of Dare Forward 2030.

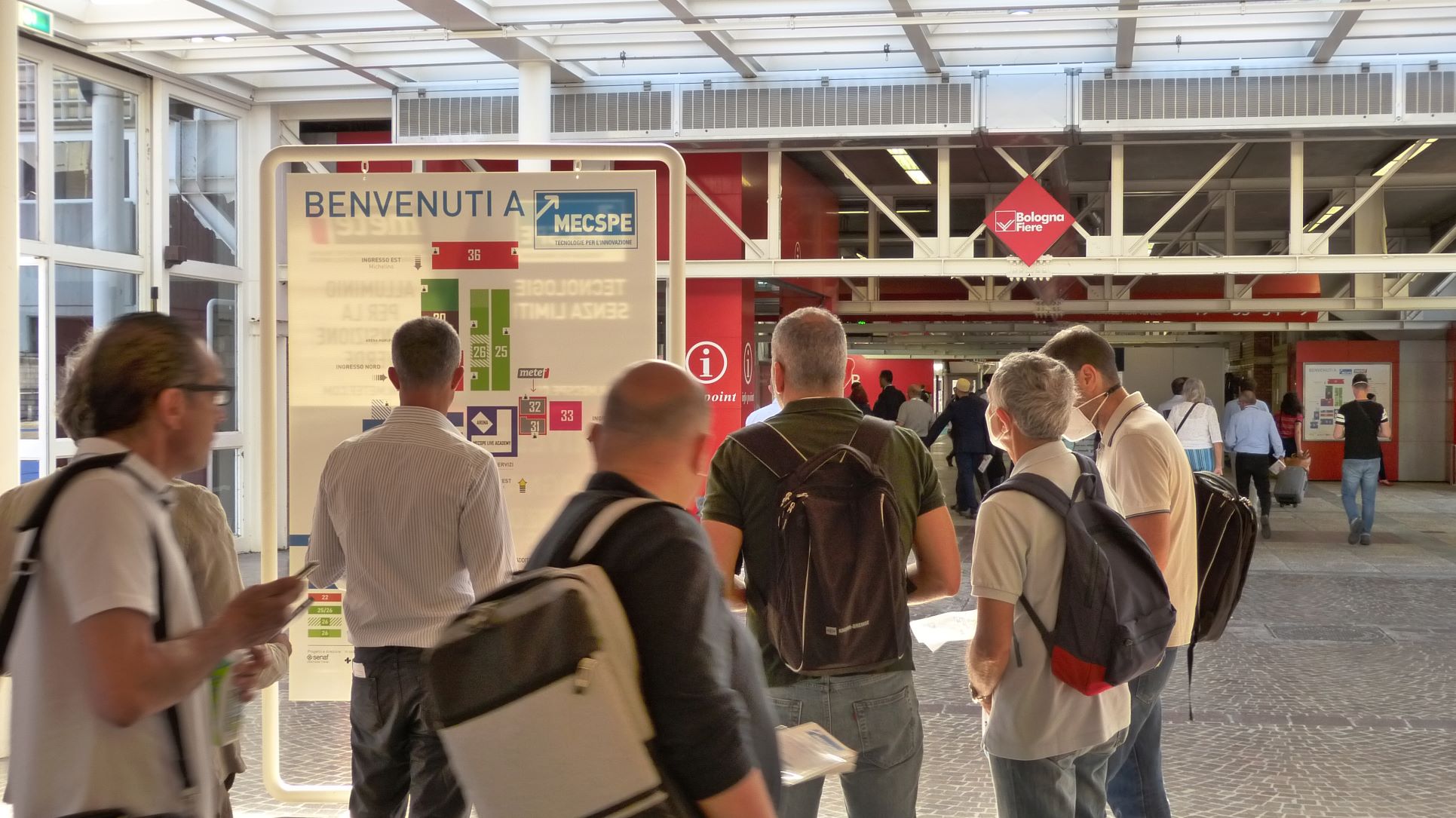

MECSPE: core exhibition dedicated to energy transition and mobility

Major focuses of MECSPE, a Core Exhibition dedicated to energy transition and mobility, the Aluminum Path by METEF and the debut of Elettronica Italia.

The year opened with encouraging signs for the industrial sector: inflation and energy prices are dropping, the automotive market is regaining share and, as recorded by Istat, November industry turnover grew by +11.5 percent compared to the same period in the previous year.

An expression of this positive trend will be the upcoming edition of MECSPE, the main exhibition dedicated to innovation in the manufacturing industry, organized by Senaf and scheduled to take place at BolognaFiere from March 29 to 31, which, as every year, gathers adhesions from all over the country and abroad.

In fact, about 2,000 companies in the industry have already decided to exhibit in the MECSPE halls, and numerous visitors are expected again this year.

Three days not to be missed

In 2023 MECSPE opens its doors to its highly qualified and professional audience for three immersive days to illustrate innovative and sustainable solutions for the supply chain, paving the way for the future of Industry 4.0 with a program developed on the three pillars of the event: training, innovation and sustainability.

In particular, this year MECSPE focuses on innovation in the energy field with a privileged look at the automotive sector.

Focus on sustainable mobility

The new Exhibition Core (Cuore Mostra) titled Energy Transition and Mobility of the Future is a 2,000-square-meter area devoted entirely to discussions on sustainable mobility issues and the technological solutions that will promote its progress.

Over the course of the three-day event, within the Cuore Mostra, the focuses of the area will be addressed through demonstration stations, roundtables and moments of debate with key players in the supply chain:

- Solutions and Technologies for the Mobility of the Future

- Machinery, Equipment and Manufacturing Systems to Optimize Efficiency,

- Reshoring for Subcontracting Supply Chains,

- Metal Replacement.

On the first day of the fair, the arena will also host the international forum 2035 AND THE AUTOMOTIVE SUPPLY CHAIN: Changing the Production Model to Respond to a Technological Transformation, in cooperation with the Tecniche Nuove Group, The German-Italian Chamber of Commerce , and the Industrial Fairs Division of Messe Stuttgart, including AMB and Moulding Expo.

During the event, a team of experts will talk about the challenges and opportunities facing the automotive industry in the run-up to 2035, through best practices and successful case histories.

Among them Alessandro Marino, President of the German-Italian Chamber of Commerce, Markus Heseding, CEO VDMA, Dino Calia, Mercedes-Benz AG, Daniele De Caro, Stellantis.

Also within the Cuore Mostra, on the last day of the fair will take place the the Aluminum Energy Summit , the event organized by METEF, the international expo for the aluminum industry, foundry and die casting, transformations, processing, finishing and end uses, present this year at MECSPE with an itinerary featuring the world of aluminum.

The aluminum supply chain is booming, especially in the transportation sector, which has the highest use of aluminum in Italy (42 percent).

It is an element that offers revolutionary opportunities for industry because of its energy and sustainability properties and its ability to be endlessly recycled.

The panel at the Aluminum Energy Summit consists of leading speakers who, drawing on their experiences in the field, will provide the audience with the tools to explore the future of aluminum and primary metal production and energy conservation through recovery and recycling as it relates to market and energy supply challenges.

On the same March 31, the International Innovation Award will be held, the initiative organized by METEF that has been established for more than a decade to enhance the innovative content proposed by aluminum companies.

The debut of Elettronica Italia

Big news for 2023 will be the holding, at the same time as MECSPE, of the Elettronica Italia show, which debuts with its first edition and will occupy Hall 28 of the Bologna exhibition centre.

The area will be representative of all industrial applications pertaining to electronics, from the design stages tithe production of components and systems, from systems to services to the subsequent market distribution of components, complex assemblies, production machines and test systems.

The goal is to offer visitors a glimpse of the entire industry from a national and international perspective.

Thematic round tables

Also scheduled at Elettronica Italia are several thematic round tables such as the March 29 “Electronics in the Mobility of the Future” and the March 30 “The Industrial Recovery of Electronics: Advantages, Regulations, Bureaucratic Difficulties,” true educational and informative moments organized by the editorial staff of the event’s official magazines: PCB and Electronics Selection, from the Tecniche Nuove Business Media Group.

«The new edition of MECSPE will be full of insights into segments that are crucial for industrial development because they intersect technological innovation and environmental impact reduction. We have worked throughout the year to bring a content proposal that is absolutely unique in the Italian exhibition scene and has an international scope» comments Maruska Sabato, MECSPE project manager.

«For 21 editions, we have been trying to offer the actors in the manufacturing sector opportunities for networking and professional growth, and this makes MECSPE an ideal business partner for companies. That is why we decided to shine the spotlight not only on the historical contents of MECSPE, but also on the energy transition, the aluminum and electronics sectors, which will be of fundamental importance for the future of the industry.»

Next appointment in Bari

Many others will be the special initiatives and demonstrations, which can be visited on the fair’s website, that will make up the rich information and training program of MECSPE, which in 2023 doubles the appointment and will also be held in Bari from November 23 to 25 with “Focus Mediterraneo” at the Nuova Fiera del Levante, an edition dedicated to the development of 4.0 technologies and a proposal increasingly focused on sustainability and innovation of production processes.