Great novelties are incoming for the bus world: an advanced modular platform that can transform any bus from ICE to electric. We are speaking of what announced by the British company Kleanbus. What good news? The removal of the diesel engine and of the hybrid powertrain from an existing bus, replacing it with a fully electric thruster, is the fastest and cheapest method to undertake the bus electrification way. It is the course travelled by the United Kingdom’s bus fleet that now will benefit from the advanced solution by Kleanbus, precisely the modular platform for the bust transformation from diesel to electric.

It is the combination of electric propulsion components tested with Kleanbus integration technology and the proprietary software: an innovative approach that allows exploiting a wide variety of batteries and motors, creating electric thrusters purposely tailor-made for a bus driver’s requirements.

The player has explained that his enhancement programme consists in a complete vehicle assessment, the removal of its diesel engine and of all its ICE associated components, scanning and prototyping of vehicle interiors, design of a customized platform, installation of a new e-drive, manufacturing, complete test process and final certification.

Due to the company’s relationships with recharge suppliers, Kleanbus organizes also the upgrade of an operator’s deposit with a suitable recharge technology, permitting them to shift to electricity without having to contact third parties, actually offering a one-stop shop.

Platform for fully electric buses

The importance of components: pre-integrated system solutions

The highly miniaturized components are the glue that holds todays’ technological world together. The most powerful semiconductors are the core of all electronic systems and the various application fields include also the electric vehicles’, so that the company aids manufacturers in operating with more efficiency. The core of pre-integrated system solutions by Bosch is the advanced drive module, ADM, which integrates the single systems of propulsion, steering and brakes in a single harmonized flexible module. Simplified interfaces and a coherent software architecture decrease the complexity and assure the optimized communication among components. This modular approach that combines hardware, software and services allows manufacturing companies to integrate the ADM according to their requirements. The rolling chassis prototype, created through the collaboration with Benteler, specialized in the production of chassis and bodyworks, proves the highest possible level of pre-integration and represents a development platform for electric battery vehicles. With its integrated safety and control technology, the new flexible smart charging cable works also without the in-cable control box with 230-V socket. Without the so-called “charging brick” Bosch cable weighs less than 3 kg. On average, it corresponds to a 40% weight reduction compared to conventional cables with control box.

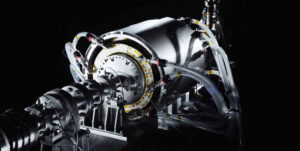

A new cooling concept: here is the durable electric motor by Mahle

Concerning this, the latest development comes from the automotive supplier Mahle: the traction motor can run indefinitely with high performance. A new cooling concept makes this technological leap possible. The new electric motor is surpassingly clean, light, and efficient and can be assembled without the use of rare earths by customer request. The new development is suitable for passenger cars and commercial vehicles as well as construction machines and tractors. With the SCT E-motor, Mahle thus becomes a full-range provider in the field of electric drives and covers all needs from e-scooters to heavy-duty commercial vehicles as well as off-road and industrial applications. The new item will be presented for the first time at IAA Transportation in September 2022 in Hanover.

Martin Berger, Vice President Corporate Research and Advanced Engineering at Mahle said: «Building large electric motors that deliver short-term high performance is easy. What was still lacking on the market until now were durable yet compact drives to make electric vehicles unrestricted for everyday use. Our new SCT E-motor is the solution. On the drivetrain side, this clears the way for the replacement of the combustion engine in all vehicle classes. In 2021, MAHLE presented a groundbreaking wear-free and scalable traction motor for passenger cars that runs very efficiently over a wide rpm range».

The SCT E-motor, on the other hand, is designed in such a way that it is particularly efficient within a certain rpm range. Despite its very compact and light design, its continuous output is more than 90 percent of its peak output. Unique on the market, this groundbreaking high ratio means a technological leap and allows the use of electric vehicles of all kinds even under demanding conditions. A classic example is driving an electric truck over mountain passes or the multiple sprints of a battery electric passenger car. These scenarios are only insufficiently covered by the electric motors available on the market up to now.

In designing the product, MAHLE opted for what is known as a permanently excited motor, since this type enables a very compact design and no energy has to be transferred to the rotor as “excitation current”. This makes the motor efficient and wear-free. Neodymium magnets, currently the strongest permanent magnets that can be produced, are used to generate the magnetic field in the motor. However, to achieve greater independence from raw material prices and geopolitical developments, the SCT E- motor can also be designed without magnets for greater independence. Thanks to the unique contactless transformer developed by Mahle, the magnet-free variant would also be wear-free and run efficiently, while only requiring slightly more assembly space.

The electric direction of the American police

It is the turn of Chevrolet Blazer EV to wear the badge in the United States police. In fact, it is not the first zero-emission vehicle chosen: before it, Ford Mustang Mach-E.

The new Chevy Blazer has a maximum power of 565 HP. Blazer EV is already sold in the versions 2LT, RS and SS. Chevrolet does not specify the technical data of the first two models with rear-wheel drive, but for the SS with all-wheel drive precisely 565 HP and 879 Nm are at stake, with autonomy of 515 km. In the more sportif modality called WOW (Wide Open Watts) Mode, the SUV can cover 0-100 km/h in less than 4 seconds. Concerning the recharge, it is possible to connect with an AC column up to 11.5 kW or 190-kW DC.

A very interesting peculiarity that concerns all versions? It is not necessary to press an ignition button to start the car because it recognizes the presence of the key and to start you must just press the brake pedal and afterwards raise your foot.

The first full electric sedan by Volkswagen

It is brand-new the release in world premiere of the new fully electric sedan by Volkswagen: ID. AERO. With this concept car, Volkswagen offers a preview of the high-end model of ID range.

With the world premiere of the concept car ID. AERO in China, Volkswagen gives an anticipation of the first fully-electric sedan by the Brand. The future mass-produced model will be part of high-end sedans’ segment.

The Chinese production’s version will be launched in the second half of 2023. Still in 2023 Volkswagen schedules to start the production of the mass-produced European model at Emden, in Germany.

Ralf Brandstätter, CEO of Volkswagen stated: «With our Accelerate strategy, we are developing the electrification of our range at full rate. After ID.4, this model will be our next world car for the regions in Europe, China and United States of America».

Moreover, MEB electric traction platform by Volkswagen benefits from reduced overhangs, a long wheelbase and an exceptionally long cabin. ID. AERO is provided with a capacious lithium-ion battery with net energy content of 77 kWh. Through the interaction between an efficient propulsion and the excellent aerodynamic properties, ID. AERO reaches a maximum autonomy of 620 kilometres on long distances

ID. AERO proves the flexibility of the fully-electric MEB architecture of Volkswagen, which can be adapted to vehicles with different shapes and sizes. From compact crossovers to SUV, from minibuses to spacious sedans: MEB can be used in all segments. Furthermore, MEB fully exploits the electric mobility possibility, which allows reaching generous autonomies, the highest level of digital connectivity and the capability of receiving over-the-air updates.

Toshiba exceeds 2700 horsepower

The Japanese giant is catapulting itself into the world of state-of-the-art electric motors, and it has entered it on equal feet, with an electric motor based on super-conductive materials, of over 2700 horsepower, 10-time more compact than a conventional motor.

The prototype by Toshiba, perfectly operating, is a superconducting thruster dedicated to mobility applications and encompasses various forefront technologies, besides semiconductors. The new motor has a maximum power of 2 MW, due to a very high-power density, and the capability of rotating at very high speed: such a power in a narrow space makes it suitable for heavy vehicles and the airplane transport, too.

Ready in production by 2030, it uses windings made with superconducting materials, (hence the name) at high temperature. They are materials with zero electrical resistance able to transfer electricity without losses at very high speed.

Ready in production by 2030, it uses windings made with superconducting materials, (hence the name) at high temperature. They are materials with zero electrical resistance able to transfer electricity without losses at very high speed.

Toshiba has also communicated that this prototype, which is currently in perfect operation, will be further implemented during next years and when it will be ready for marketing it will have even better technical features and performances.

Lightyear, the solar car is reality

Here is the definitive model of Lightyear 0 electric solar car, definitive version of the famous Lightyear One that required 6 years of development.

Why has its name been changed into “zero”? To underline the scarce need of the plug-in recharge that the company deems one of the strongest limits in environmental terms. According to the calculations carried out by the company, in fact, a commuter who travels 50 km a day for the commute home-work can comfortably travel over 1000 km with a single recharge, simply parking the car outdoor.

The Dutch manufacturer, in fact, refers to performance that reach 695 km in the WLTP autonomy cycle, with 60 kWh battery. The surface, corresponding to five square metres of solar panels with double curvature, allows achieving energy to reach even 11,000 km of yearly mileage.

How much does it cost? 250,000 Euros. However, for 2024 Lightyear has also a second car under development, with the temporary Lightyear Two name, devised for the mass market, with a starting price of around 30,000 Euros.

The electric Ferrari is on its way

It is official: in 2025 the electric Ferrari will be on its way.

The car will be designed and manufactured in the historical Maranello factory and concerning this a new structure specifically dedicated to electrification is planned. What will the key features be? The electric Ferrari will be equipped with a series of innovative technologies in-house developed, including high-efficiency electric motors, developed thanks to the expertise in races, with top-level power performances.

Batteries will be in-house developed, too: handmade and of structural type, integrated into the bodywork to decrease weights and overall dimensions. Ferrari has announced that it will succeed in enhancing batteries’ energy density by 10% every two years.

Battery cells, supplied by a subcontractor and in-house assembled, will be combined with specific software and cooling systems designed by its own engineers.

The electric Ferrari will have the same performances as the other models, the same technology for the dynamic vehicle management. However, what will be the rampant horse’s electrification steps?

Ferrari has announced it will reach the climatic neutrality by 2030. The roadmap of its proposal provides for a mix of models within 2026, represented by electric cars by 5%, by hybrid cars by 55% and by cars with endothermic motor by 40%. In 2030, percentages will be the following: 40% pure electric; 40% hybrid; 20% ICE.

Yamaha’s electric strategy

The Japanese Yamaha is not lacking in the appeal of the brands ready for the electric, being committed to its Switch On, the manufacturing strategy in which Italy is engaged with targeted actions and interventions. This course towards the electrification includes the new Harmo outboard engine, the scooter Neo’s, the concept of E01 scooter, the golf car and the motor of the e-bike.

The manufacturer makes technology its cutting-edge: compared to 15 years ago, a model 125 cc Euro 5 with state-of-the-art Blu core motor produces about -30% less of CO2 grams.

The witness by Andrea Colombi, Country Manager Yamaha Motor Italia is particularly proud: «We are pioneers in the experimentation of innovation at the service of individual mobility and of passion. We have been committed to the reduction of emissions for over thirty years, without ever compromising and giving up quality, entertainment, user-friendliness and reliability».

eVTOL, electric motors for the Lilium Jet

The German startup Lilium has recently announced a partnership with the avionics provider Honeywell and the Japanese automotive specialist Denso to co-develop and manufacture electric motors for the Lilium Jet.

The eVTOL aircraft strongly relies on its 30 ducted fan motors mounted on wings and canards. The propulsion system needs to be powerful, light and most of all extremely reliable. According to Denso, which provides both stator and rotor of the motor, delivering an output of 100 kW and weighing less than 4 kg.

In the meanwhile, the company has also shared on 31st May the achievement of the main wing transition. The test verified the critical phase in which the aircraft switch from hover to wing-borne flight.

The test campaign will continue in the summer, focusing on the transition of the forward canards and the high-speed flight.