The Research Group at Department of Industrial & Information Engineering & Economics of the University of L’Aquila has been working for many years in the field of designing, prototyping and testing of innovative motors for automotive applications. It is recently involved in a H2020-GV European project focused on contributing to avoid the use of rare-earth magnets through the development of a next generation of electric drivetrains, ensuring the industrial feasibility for mass production while focusing on the low cost of the manufacturing technologies.

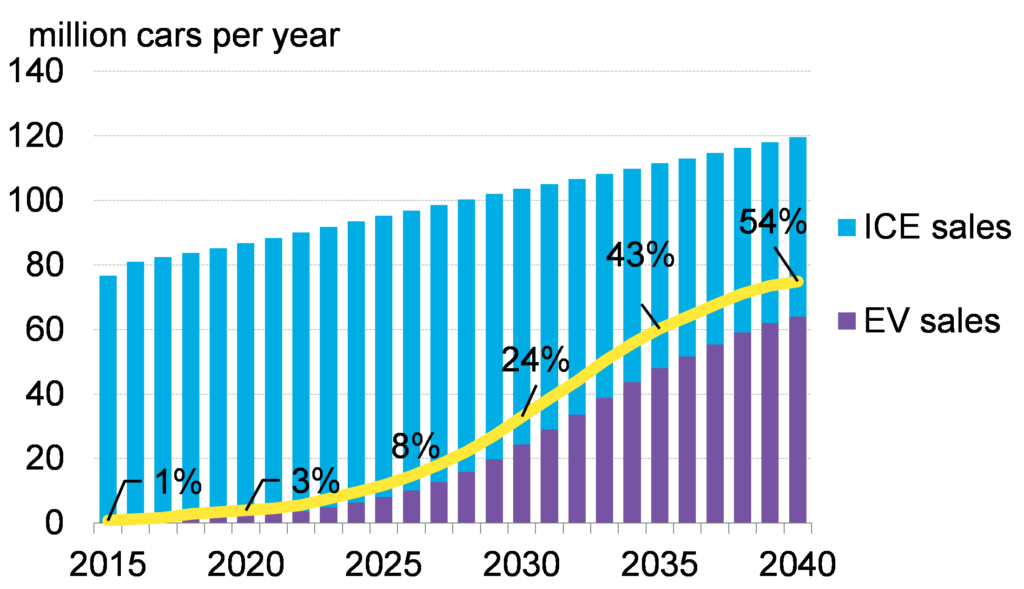

The impact of internal combustion engine on the environment has led to efforts to replace it by alternative propulsion systems, among which the electric motor has become the primary candidate. The electric car market is booming and in the next twenty years a surge electric vehicles (EV) sales is expected which should exceed that of traditional ICE cars, as shown in Fig.1.

The new technologies for energy storage and powertrains play a critical role in the development of the electric vehicle market. At motor level, key components and innovative materials must be integrated in the current motor designs. Recent advances in materials, power electronics, control systems have contribuited to new energy efficient and performant powertrains adopting innovative motor technologies.

The basic characteristics of an electric motor

The requirements of the electric motors for EVs are different from the conventional ones used in the industrial applications. The most challenging specifications are a reduced size and high efficiency in an extended speed range. For good overloading and wide speed range capability, the machine is usually water cooled with a water jacket around the stator core.

The basic characteristics of an electric motor are the following:

1. high specific power and specific torque;

2. very wide speed range;

3. high efficiency over wide torque and speed ranges;

4. wide constant-power operating capability;

5. high reliability and robustness for vehicular environment;

6. reasonable cost.

Since the EV operates over a wide torque-speed range in various driving conditions, the motor design should be aimed to achieve overall energy saving over a driving-cycle of the vehicle (e.g. WLTP, NEDC, UDDS). There are many demands for developing propulsion systems with high power density, high efficiency and low cost.

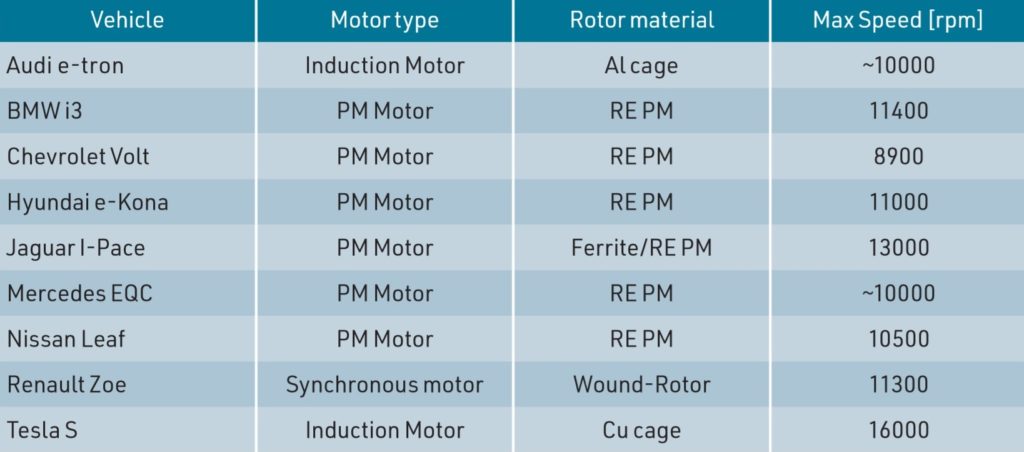

The research in this field has been intense in the past few years and different types of electric machines have been studied and proposed. The vast majority of motor solutions rely on Permanent Magnet technology using rare-earth magnets. Table 1 summarizes the existing electric vehicles in the European & US markets, specifying the technological solution for the traction motors.

From the Permanent Magnet Synchronous Motor

The Permanent Magnet (PM) Synchronous motors are more attractive and the main advantages are their inherently high efficiency, high power density, and high reliability.

The PM motors are relatively easy to control and exhibit excellent performance, in terms of maximum torque per ampere control and optimal extended speed operation. Different types of PM machines are proposed according to the position of PMs in the rotor and can be classified as surface or interior mounted magnets.

The high and volatile cost of raw materials for magnets makes uncertain their long-term availability, especially since the electric vehicle technology is going to be manufactured in mass production. Also, PM motors present several technical drawbacks that limit the performances of the motor, in particular the demagnetization effect if the temperature of the motor exceeds its operating conditions. Therefore, there is a growing attention in alternative solutions that include rare-earth (RE) free machines or reduced RE-PM machines.

The Synchronous Reluctance Motor

The Synchronous Reluctance Motor (SynRM) is becoming of great interest in the recent years and represents a valid alternative for electric and hybrid vehicles due to its simple and rugged construction. The main advantage of the SynRM relies on the absence of the rotor cage losses or PM losses, allowing a continuous torque higher than the torque of an Induction Motor (IM) of the same size. Other important features are:

1. the rotor is potentially less expensive than PM motors and IM ones;

2. the specific torque is acceptable and it is not affected by the rotor temperature;

3. the field-oriented control algorithm is simpler with respect to the one of IM drives.

The conventional SynRMs are known for their lower specific (peak) power and specific (peak) torque (compared to the PM motors), higher noise and lower power factor.

Despite these drawbacks, it is possible to obtain high torque density and high efficiency motors through an optimized rotor design.

Specific power in SynRM is enhanced by increasing the rotor operating speed and the flux-weakening region. Nevertheless, the optimal geometry for motor performances needs to be refined to guarantee the mechanical integrity of the rotor at high speed.

New solutions for the power traction systems of electrical vehicles

The Research Group at Department of Industrial & Information Engineering & Economics of the University of L’Aquila has been working for many years in the field of designing, prototyping and testing of innovative motors for automotive applications. The Group is recently involved in a H2020-GV European project labelled “RefreeDrive” – Rare Earth Free e-Drives for low cost manufacturing.

This project is focused on contributing to avoid the use of rare-earth magnets through the development of a next generation of electric drivetrains, ensuring the industrial feasibility for mass production while focusing on the low cost of the manufacturing technologies.

The aim is to study and develop new solutions for the power traction systems of electrical vehicles, based on Brushless AC electrical machines rare-earth magnet free.

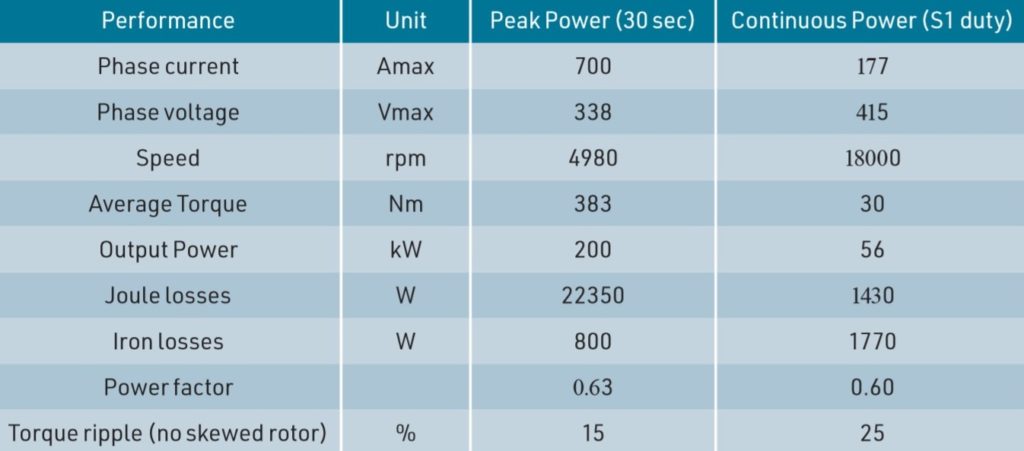

Through the development in the electric motor topologies within the project, advanced performance has been achieved in terms of specific power, power density and efficiency, compared to a current electric vehicle taken as a reference (Tesla Model S 60). The ReFreeDrive Consortium is composed of 13 partners in six European countries and the team of University of L’Aquila took in charge the design of high speed Synchronous Reluctance motor (200 kW peak power) for a full-electric premium vehicle. The goal was to design a liquid cooled SynRM than could satisfy the imposed requirements shown in the Table 2.

Performances while respecting the target components cost

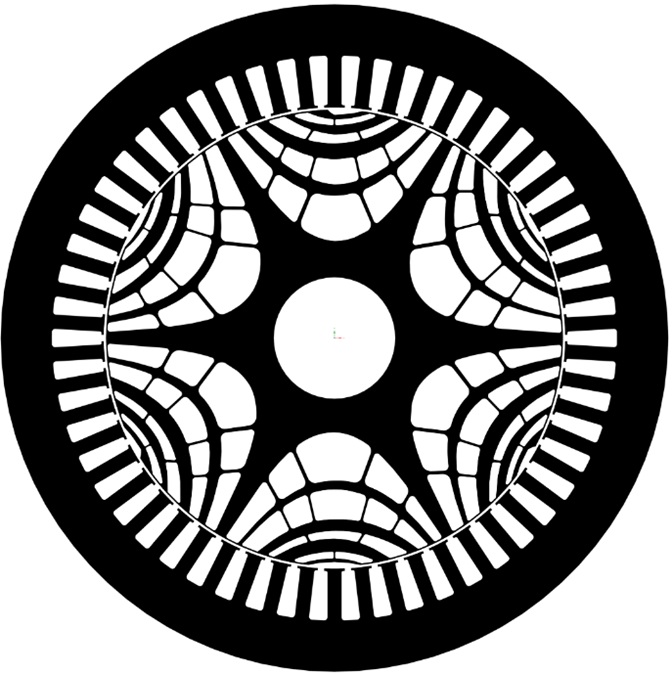

The avenues indicated above have required a complex optimization process for matching the desired motor performances while respecting the target components cost. Specific sizing procedures and optimization algorithms have been used for the design refinement and the proposed solution presents an innovative rotor structure with “fluid shaped” barriers and radial ribs.

Fig.2 shows the cross section of the 6-pole SynRM.The rotor with asymmetric shape has multiple “ribs” that connect the segments to each other axially and transversally: these connections maintain enough mechanical integrity in the rotor structure when rotational forces are applied at high speed.

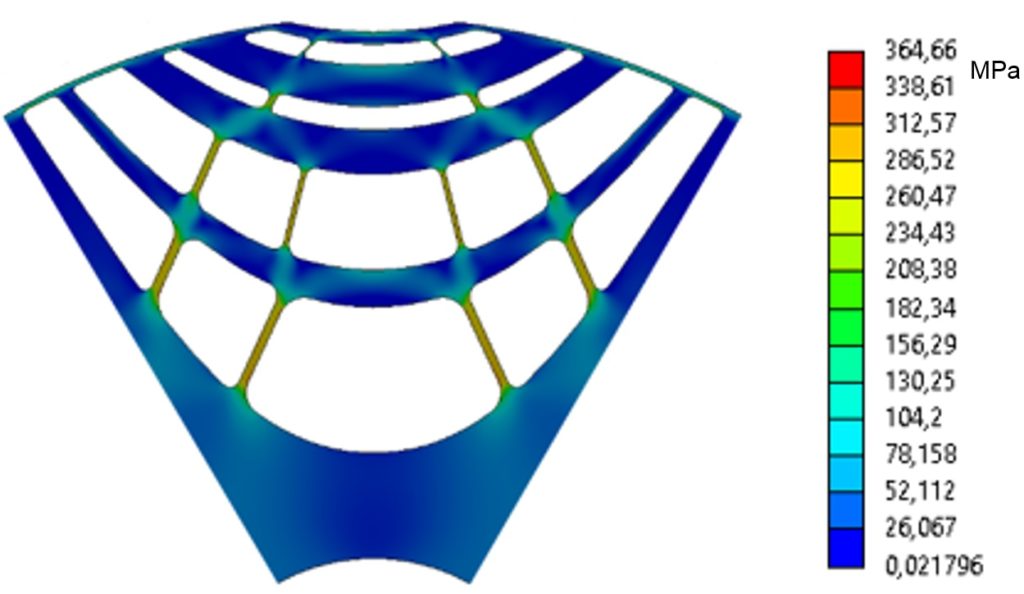

The optimal positioning and the optimal thickness of the rotor ribs have been refined by the “topology optimizer” coupled to a mechanical Finite Element software; this algorithm has allowed to optimize the quantity and the positioning of the mass needed by a mechanical part to sustain the stress.

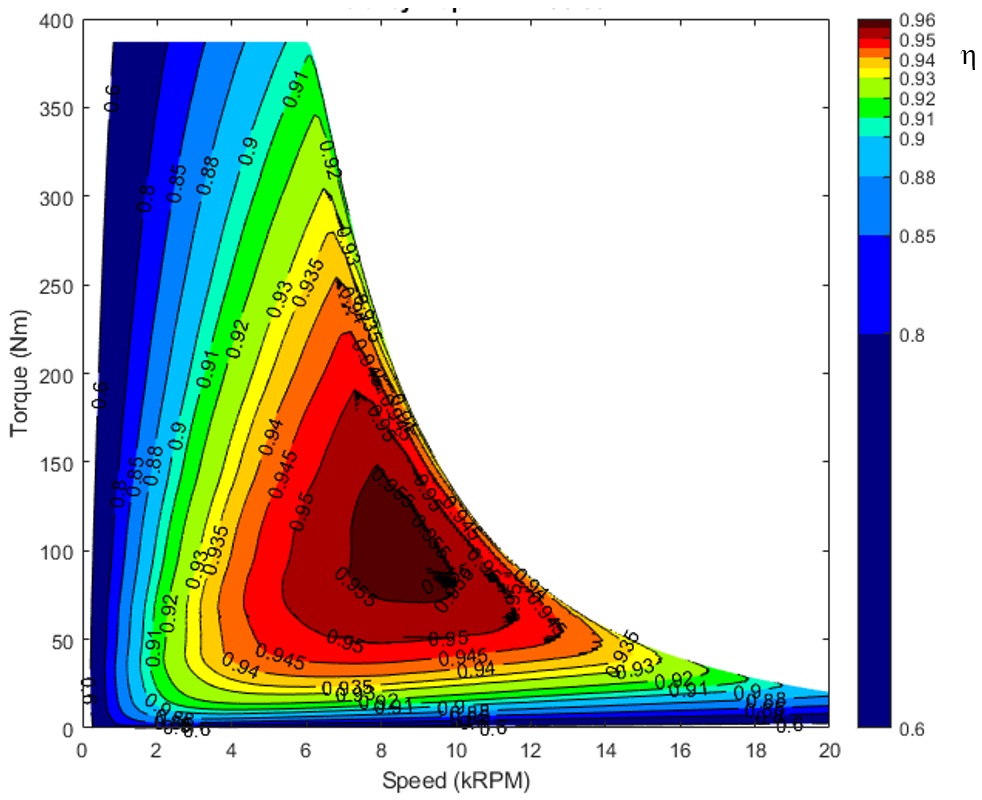

The main motor performance at peak power and continuous power are listed in Table 3 while Fig.3 presents the efficiency map in motoring mode: the peak efficiency is about 96% and the maximum torque is 383 Nm with a peak power of about 250 kW at 6200 rpm. At maximum speed (18000 rpm), the maximum power is 56 kW: these performances fully satisfy the requirements given in the Table 2.

The mechanical equivalent stress map at max speed (18000 rpm) is reported in Fig.4: the results are satisfactory and confirm that the rotor structure is able to withstand mechanical stress at high speeds and it satisfies the mechanical limits of the chosen electrical steel.

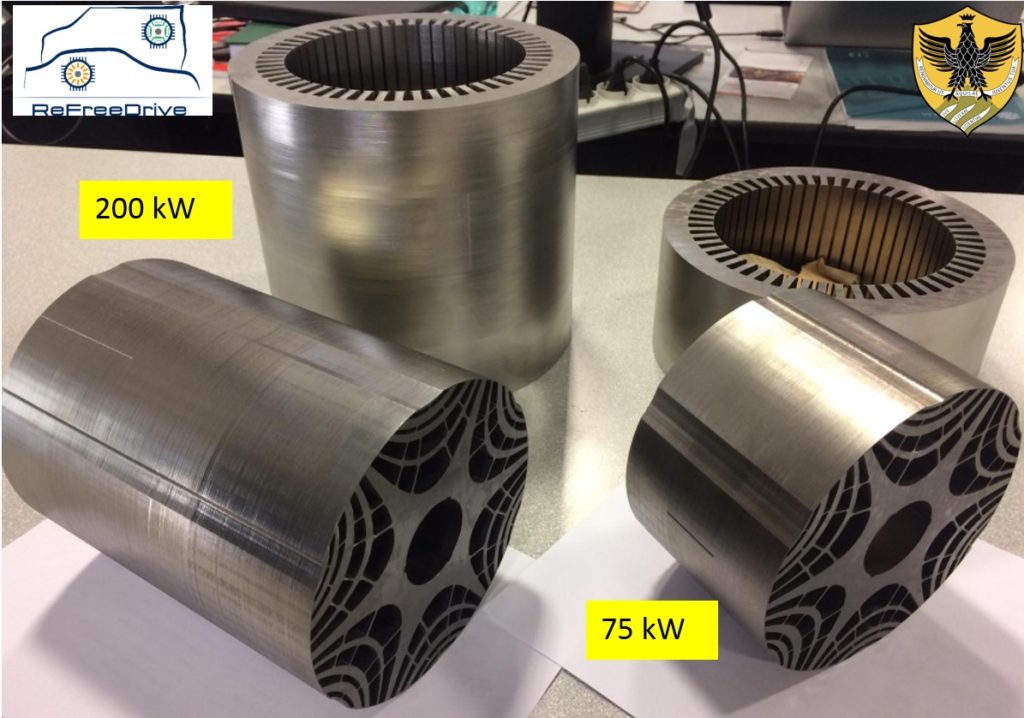

A lower power machine (75 kW peak power) has been scaled from the 200 kW design by only changing the stator winding and stack length in order to contain the manufacturing costs.

Two protoypes have been realized and Fig. 5 shows the stator and rotor cores of the 75 and 200 kW sizes.

The power electronic has been designed by R13 Technology (a University of L’Aquila spin-off) for a direct integration with the SynRM housing sharing the motor cooling system.

The powertrains (75 and 200 kW) will be tested in real driving conditions on a test bench and vehicle demonstrators.

by Marco Villani, University of L’Aquila, Dept. of Industrial and Information Engineering and Economics

Marco Villani received the M.S. degree in electrical engineering from the University of L’Aquila, Italy, in 1985. He became an Assistant Professor of power converters, electrical machines, and drives in 1993. In 1990, he was Research Fellow at the University of Dresden, German, and in 1995 at the Nagasaki University, Nagasaki, Japan. In 1998 he cooperated in two SAVE projects concerning the “Energy efficiency improvements in threephase Induction Motors” and the “Barriers against energy efficient motor repair”. He has been involved in National Research Projects and took the responsibility of several research contracts between the University of L’Aquila and industrial partners. He is currently associate professor of Electrical Machines Design for the Master-level degree courses of Electrical Engineering at the University of L’Aquila. His research interests are focused on modeling and design of electrical machines, high efficiency induction motors, optimization techniques for the electrical machines design, Finite Element analysis of electric motors, design of PM synchronous motors and Reluctance motors for industrial, automotive and aerospace applications. He is author of more than 160 technical papers in scientific journals and conference proceedings.