Hypercars push the exclusivity concept to extremes: they are vehicles that are part of very limited series, with sports aesthetics and exasperate performances, by far exceeding conventional sports cars. Often, hypercars propose innovations in advance compared to the other cars and they are used as test bench to diffuse determinate technologies on more “reachable” vehicles.

We are speaking of a parallel world, of an extra-luxury market that exists thanks to an elitist niche of people looking for adrenaline, fond of motors and performances, willing to pay very high amounts to own and to drive vehicles that represent the utmost expression of the automotive technology. Hypercars satisfy on four wheels man’s natural bent for overcoming limits and it is unavoidable that such extreme cars make us dream, engaging in the design smart minds of skilful and enthusiastic engineers like Francesco Mastrandrea from AVL, the interviewee of these pages.

What a hypercar is

The engineer Francesco Mastrandrea has helped us to define “hypercars”: vehicles that belong to very limited series, with sports aesthetics and exasperate performances, by far exceeding the traditional sports cars. «These cars – the engineer Mastrandrea explains us – must be framed in the context of their historical period and borders are anyway undefined. A car considered hypercar in the Eighties, like for instance the F40, today would be deemed “just” a sports car, neither with particular qualities; let us think that a current Alfa Romeo Giulia Quadrifoglio Verde, apparently a common sedan, has 510 horsepower and overall performances that exceed a hypercar dating back to 25 years ago».

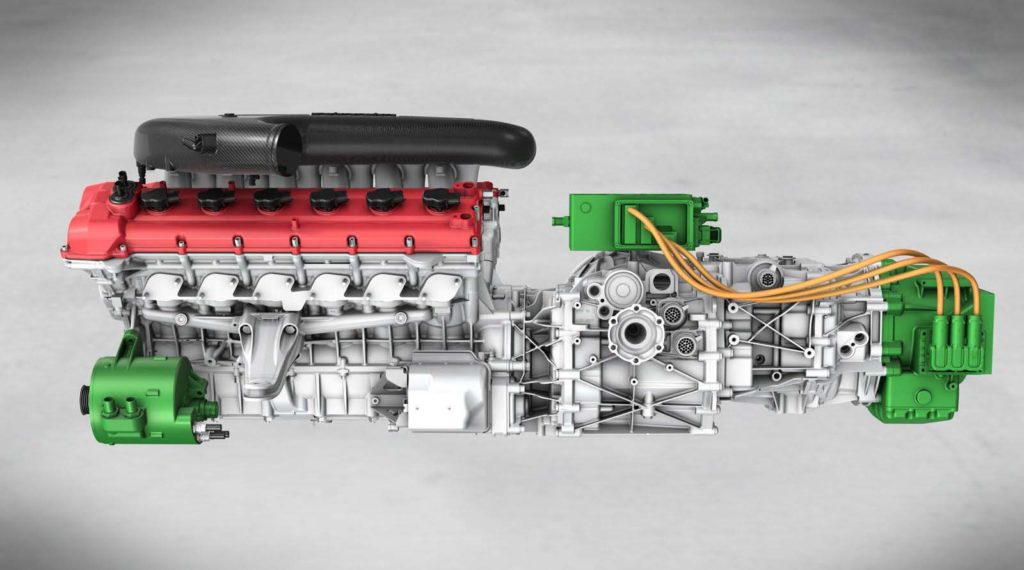

How were they born and what is their origin? The motivation should be sought in the precise essence of man and his will of overcoming the imposed limits. There have always been people who are not satisfied with standard vehicles and the hypercar concept was devised precisely with the advent of cars; we remember that in the Sixties there were already several brands that modified “standard” cars to create unique models intended for exclusive users. «Often, hypercars propose innovations in advance compared to the other cars and they are often used as test bench to diffuse determinate technologies on more “reachable” vehicles. “LaFerrari”, for instance, with its hybrid powertrain has anticipated some years earlier the use of this technology on the rest of Ferrari range».

for each wheel.

Hypercar VS Supercar

If performances, very high cost and sports aesthetics might almost be shared by hypercar and supercar, there is a neatly different factor: the production modality.

«I had the lucky opportunity – told us the engineer of AVL – of living some phases of the creation of these vehicles. Hypercars further heightens the exclusivity concept: very few are produced upon customers’ specific demands and a direct relationship between buyer and manufacturer often emerges, with production logics that are more similar to the ones of an expert artisan.

Another differentiating factor concerns the availability on the market. Sport cars, even if with long wait times and for few people, are accessible because they are anyway catalogue cars. The price as well shares in creating a gap between the supercar and the hypercar: if the cost of a sports car range from 300 to 500,000 euros, a hypercar generally starts from one million of Euro, with some small exceptions. «Not many people in the world can afford it but more than we can imagine. They have manufactured 500 Ferrari hypercars whose cost is 1.7 million Euros and they were fully booked before the production started. In this market slice everything is relative: if you have already a yacht moored at the port and other three Ferrari in the garage, spending almost 2 million Euros for a car is quite coherent, obviously in that context».

Another aspect that characterizes this segment is the second-hand market that has opposite logics to the “traditional” one”. «Recently, a Ferrari 250 GTO of 1962 was auctioned for the record figure of 48,405,000 dollars. Then, they are vehicles not affected by devaluation but, contrary to normal supercars, they gain higher value as soon as the leave the dealer».

What are the main pluses for an electrified hypercar?

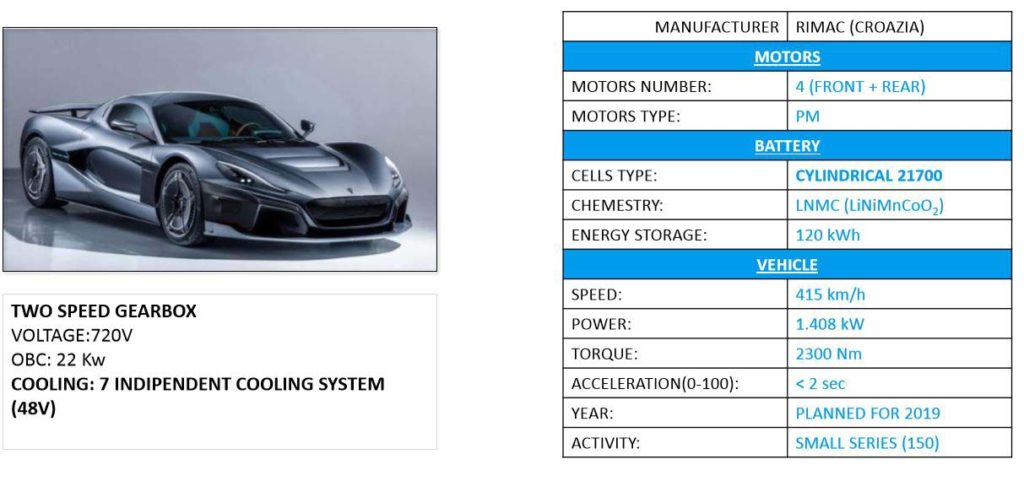

Primarily, the maximum torque at zero revolutions granted by the electric propulsion that allows immediacy in the response to the impulses of the accelerator and not losing time in gear changes. I add that the centre of gravity is positioned lower than in an endothermic vehicle for the favourable positioning of the battery, with remarkable advantages linked with load transfers; this improves the longitudinal performances, then acceleration and braking. Electric hypercars are often provided with four independent motors, therefore it is possible to deliver adequate torque to each wheel and to exploit the adhesion limit of the tire, optimizing its traction qualities. The use of electronic differentials in a vehicle with endothermic motor does not allow a so efficacious control.

What are instead, still today, the most critical aspects?

Mainly the weight that is strictly connected with the energy density of the battery. Today it reaches about 250 wh/kg, still not sufficient to be competitive in terms of revolution performances with an endothermic vehicle. Having two independent motors on the same axle means to have to emulate a traditional differential but with licit perplexities concerning safety: a wrong signal to one of the two motors while the vehicle is engaged in a curve can have disastrous consequences. Therefore, huge efforts are necessary in this ambit, to optimize performances and safety. If a great quality of an electric motor is the easy development of a high instantaneous power, the delivery continuity represents a critical element. Rimac hypercar, for instance, declares powers approaching 1500 kW, probably it succeeds in maintaining them just for few seconds and only under certain conditions of external temperature and battery charge. The endothermic motor, on the contrary, grants the same performance for a prolonged time, with the exception of modest variations depending on environmental conditions like temperature, pressure and relative humidity. The challenge consists in managing the cooling so that temperatures remain as slow as possible; one of the main dangers is precisely the heat released by electric components and this limit compels to declass significantly the torque delivered to wheels when you pursue the highest performances. Creating a high-performance electric vehicle is a committing, but at the same time exciting, challenge because it deals with consolidated technologies, refined in dozens of years. Certainly, the endothermic vehicle starts in advantage but we are quickly recovering».

What is the next frontier?

Operation voltages exceeding 1000V and batteries at the solid state. We will see incredible things…

What is your favourite hypercar?

It is the fully electric hypercar that we would like to develop here, in our technical centre, and we hope we will soon have the opportunity. We work at research and development for most of our time and it is part of our job to recognize as passable those barriers that others deem unsurmountable.