Conventional materials and technologies are by now reaching their performance limit. It is then clear the need of turning to a “revolutionary” synergy that succeeds in tracing a new frontier of development able to change the entire system of the electrical machine industry.

Electrical machines can still boast a notable improvement potential and, nevertheless, they are considered a quite mature technology. The constant improvement has been certainly achieved by using magnetic cores made of special steels, or with low magnetic loss, and high power density permanent magnets that provide low-loss excitation for machines, without however determining a revolutionary development. A real step forward, for a gradual change in the improvement of electrical machines’ performances, can occur only with the new rising materials, like for instance nanomaterials, also when combined with advanced technologies. A winning synergy can be established between new materials and forefront process technologies and it will undoubtedly be able to innovate the industry of electrical machines.

More efficiency and sustainability through nanoscale materials

The radical progresses that might substantially influence the efficiency and the performances of electrical machines require the introduction of new materials needed to replace the ones traditionally used.

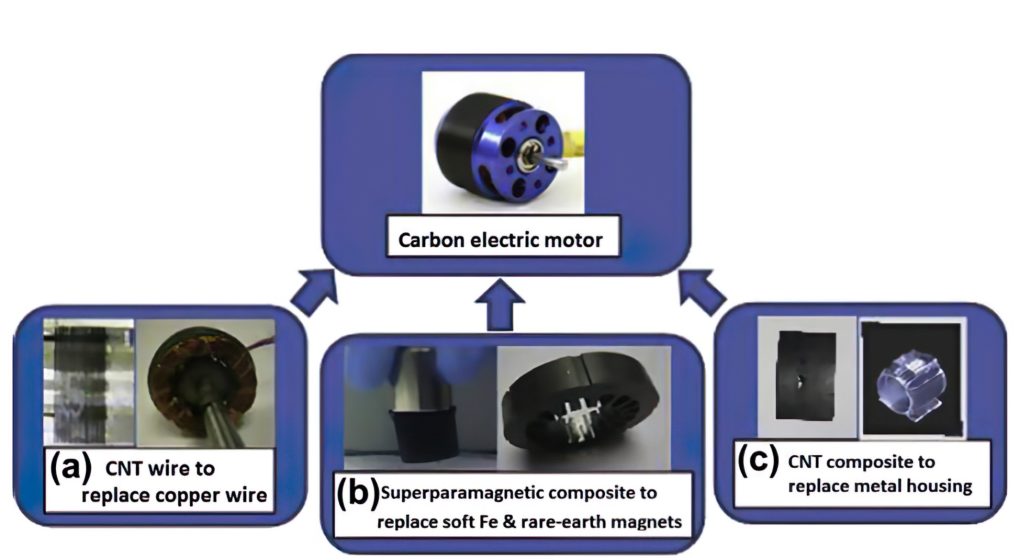

Multifunctional electromagnetic materials, such as carbon nanotubes, better known as CNT, and magnetic-core superparamagnetic nanoparticles are the new materials that can be used to replace respectively copper and iron in the conventional motor, and to design a light high-performance electric motor that can be a state-of-the-art example of future energy conversion devices.

The need of increasing the overall efficiency of the motor system, in fact, has never been so high. Owing to the increment of energy costs and the serious concerns for global CO2 emissions, reaching the highest possible efficiency of the motor system has become a fundamental priority. Motorized systems used by manufacturing industries play an important role in national energy profiles. The variety and the differentiation of future systems will be oriented towards a higher power density, with increasingly efficient and compact motors.

However, conventional materials and technologies are by now reaching their limit. Therefore, it is evident the need of a “revolutionary” technology that by will enabled just by turning to new materials: “nanomaterials” might change the entire system of the electric machine industry.

The materials used to make motors have not changed a lot since 1910 to today. Copper and iron are still used and rare earth magnets are exploited to obtain the nest performances. Today there is instead the possibility of using nanoscale materials to develop next-generation electric motors that are sustainable and more efficient. The future forefront electrical motor will require the integration of the fundamental research concerning the development of nanoscale materials with the re-engineering of the electromagnetic design of the motor itself, in order to overcome the limits of existing materials.

Carbon nanotubes, CNT, represent an extraordinary family of new materials characterized by as extraordinary electrical, thermal and mechanical properties.

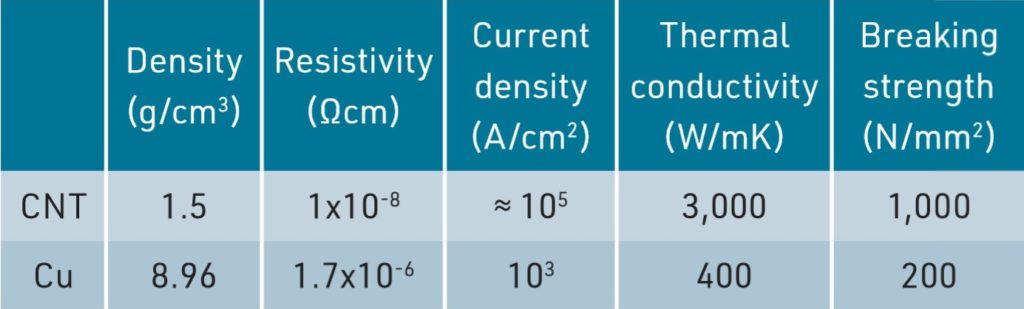

Carbon nanotubes feature a density of 1.5 g/cm3 against 8.96 of copper; resistivity reaches 1 x 10-8 Ωcm, against 1.7 x 10-6 of copper; ≈ 105 A/cm2 is instead the current density, against 103 of copper. Thermal conductivity and breaking strength appear quite different, too: 3,000 W/mK and 1,000 N/mm2 for carbon nanotubes, against respectively 400 W/mK and N/mm2 of copper, as synthesized in the table (1).

Exploiting advantageously these intrinsic properties is based on the capability of systematically synthesizing, characterizing and integrating standardized materials into real devices. Therefore, almost the entire electric motor can be eventually manufactured with nanomaterials.

The main nanomaterials under development phase are the following:

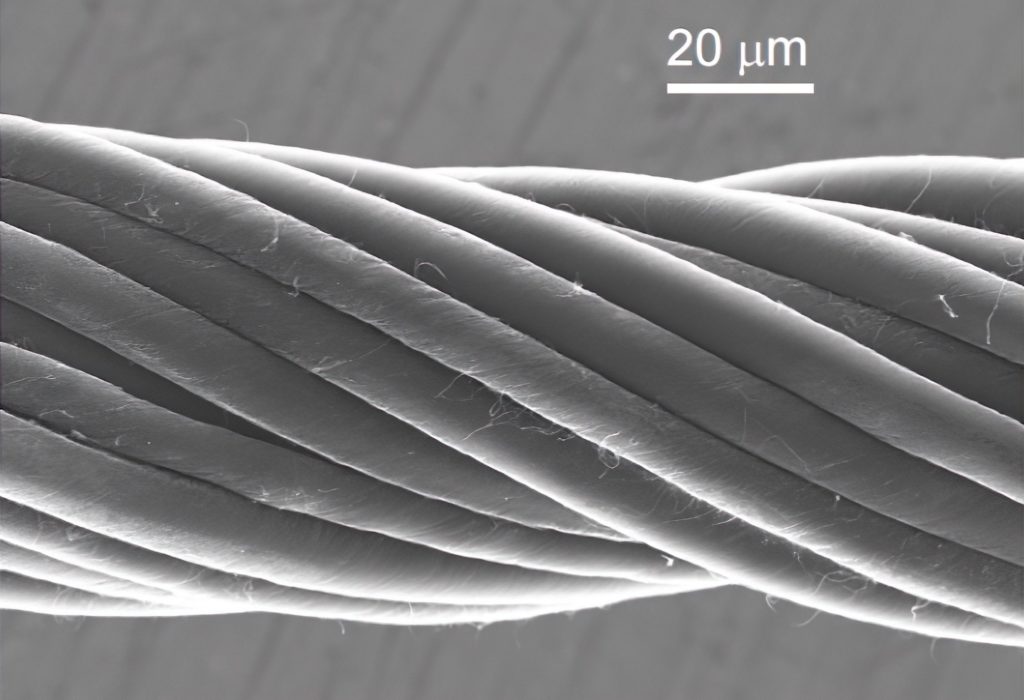

1. Strong, light, electrically and thermally conductive CNT wire.

2. Superparamagnetic nanoparticles.

3. Hard magnetic nanoparticles.

4. Composites reinforced with carbon nanotubes.

Carbon nanotubes can replace the copper wire

The best carbon nanotubes have proven a conductivity widely exceeding best metals’. Therefore, the future windings implemented with such materials might have a double conductivity (100 MS/m) compared to current copper ones.

If we keep electrical machine design parameters unchanged and we replace only copper with future carbon nanotube yarns, we can reduce losses in windings by Joule effect to half of the machine’s current losses. Carbon nanotube yarns are much lighter than copper and more ecologic, too.

Therefore, the copper replacement with nanotube yarns should significantly decrease CO2 emissions connected with the production and the operation of electrical machines. Moreover, the sizes and the masses of the machine might be reduced and motors might also operate at significantly higher temperature than current ones.

In fact, a further highlight of CNT wire concerns the resistivity that decreases when the temperature rises (at environmental temperature, the resistivity temperature coefficient is negative, -0.2 x 10-3 /K), which is an advantage versus copper. Reducing the electric resistance of the nanotube yarn will be a future target to increase the power and to improve the efficiency of carbon motors.

Another advantage of CNT fibres consists in the fact they are constituted by very thin sub-conductors that should considerably limit the possibility of skin effects at the frequency of the electrical machine. Moreover, supposing future commercial CNT wires will be manufactured starting from multi-fibres that can be easily transposed, neither circulating currents are likely to appear. Both the skin effect and circulating currents can be very noxious in traditional high-current windings and result in higher resistance in AC.

Therefore, it should be possible to implement electrical machines with carbon windings that can work at higher operational temperatures than those today usually applied for their design. This is due to the fact there will be no increase of losses by Joule effect at the temperature rise.

Although it is not foreseen carbon nanotube conductors will soon replace copper ones, it is plausible to expect that in the short term CNT materials allow the creation and the development of new applications and new devices, wherever the same CNT wires can take advantage, compared to copper, in terms of lightness, flexibility, flexural strength, resistance to corrosion, high resistance and high modulus of elasticity, which is 103 kN/mm2.

Superparamagnetic nanoparticles, hard magnetic and CNT reinforced composites

As previously mentioned, among the main nanomaterials under development phase stand out also superparamagnetic nanoparticles and hard magnetic nanoparticles. The first, used in a polymeric matrix, produce an assembly of particles with low hysteresis and high saturation, then it is possible to manufacture a light-material magnetic core, which transports the same flux as the ferromagnetic one, or a higher one, and minimizes the loss of parasitic currents.

Hard magnetic nanoparticles are instead based on not critical, easily accessible, stable and easily recyclable 3D metals, like iron (Fe), Cobalt (Co) and Nickel (Ni), with a magnetization at high saturation and magnetic anisotropy.

Such nanoparticles can be used as constitutive elements for the manufacturing of sintered and alloyed permanent magnets, as replacement of permanent magnets currently used in electric motors containing critical rare earth elements at high cost. This new generation of permanent magnets can share in solving the sector dependence on rare earth metals, at the same time improving magnetic performances. This might be important for the development of electric cars based on rare earth elements for their powerful electric motors. Since nanocomposites feature better magnetic force/weigh ratios, the new devices, like electric motors, can be equipped with lighter magnets, so reducing their sizes and the weight as well. In that way, it would be possible to enhance the device performances while decreasing implementation costs, making the mass production much simpler.

The last, but not least, family of nanomaterials under development phase includes the composites reinforced with carbon nanotubes. These materials will be increasingly available on trade with the rise of the production of CNT that, due to their intrinsic properties, will provide a much higher resistance than carbon nanotube fibres, in addition to a higher thermal conductivity.

Prerogatives, the latter, that will allow implementing the structure of the electric motor, the housing and the shaft, increasingly light and thermally conductive.

Hoping that progresses will be constantly confirmed in all four nanoparticle structures mentioned, there will be soon the conditions for the development of a “new generation of electrical motors”, which will be manufactured almost in their entirety with nanoscale and nanostructured materials.

New frontiers, trends and future developments

In today’s global more and more competitive market, the demands for higher power density, compact motors, lower costs and more reliability are driving the need of introducing an innovative approach to the use of new materials and advanced technologies, to allow the development of a new generation of electric machines and systems. The recent technological progresses in nanomaterials have opened new horizons and marked out the new frontiers for macroscopic applications.

The carbon nanotube wire, CNT, the magnetic core made with superparamagnetic nanoparticles and permanent magnets made with hard magnetic nanoparticles are new materials that can be used to replace respectively copper, iron and rare earth permanent magnets in conventional motors; this will permit to design a high-performance light electric motor that can be an example of a new generation of energy conversion devices. Other advantages of carbon motors undoubtedly concern also the fast acceleration, the high torque and the capability of operating at high temperatures and at higher speeds. The state-of-the-art motor must be then designed according to the synergy of the integration of different materials that exceed the limits of existing materials and exploit the properties of new materials.

The collaboration must reach an integration level where universities, designers and producers will work together to improve the understanding of the advantages and the challenges regarding the application of new materials and of advanced technologies, to allow the development of a new generation of electric motors that will play a fundamental role in industry and will envisage a new future for the society. I hope this challenge will be increasingly sustained and supported by potential stakeholders, so that Italy can release on the market the first electric motor made with nanomaterials and respective advanced technologies.

by Enzo Chiricozzi, Professor Emeritus of Electrical Machines University of L’Aquila

Enzo Chiricozzi graduated in Electrotechnical Engineering at “La Sapienza” University in Rome. Full Professor of Electric Machines at the Faculty of Engineering of University of L’Aquila, he was appointed to various roles, like: President of the Graduation Course in Electric Engineering, Director of the Department of Electric Engineering, Dean of the Faculty of Engineering, Deputy Rector for the University Placement and the relationships with the labour world. In 2012, with decree by MIUR, Ministry of Education, University and Research, he received the conferment of the title of Professor Emeritus of University of L’Aquila. His research activity, developed in the scientific area of Electric Machines and Electric Drives, with in-depth study of various themes (torsional oscillations of big generating units; analysis of the dynamics of a heterogeneous group of asynchronous motors; the saturation problem in electric machines; high energy efficiency asynchronous motors; analysis of the dynamic operation of electric generators of synchronous and asynchronous type operated by wind motors; drives in DC and in AC controlled by microprocessors), has been acknowledged by the scientific community on a national and international scale.

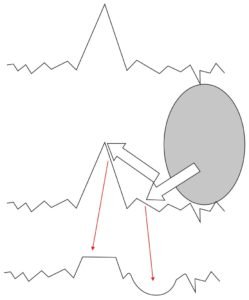

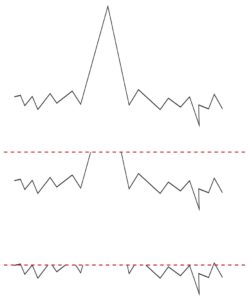

Acoustic holography technique was used for analysis of the sound source. Acoustic holography technique is a method that is used to estimate the sound field near a source by measuring acoustic parameters away from the source via microphone array. This is a well-known technique and its description can be found in (Refs. 16–17).

Acoustic holography technique was used for analysis of the sound source. Acoustic holography technique is a method that is used to estimate the sound field near a source by measuring acoustic parameters away from the source via microphone array. This is a well-known technique and its description can be found in (Refs. 16–17). Both motors were located relatively close to each other, and both of them were driving centrifugal pumps of the same type through direct coupling. Both motors where operating at the same load level. Motor case 1 is considered healthy while motor case 2 is considered to have a combination of static eccentricity and soft foot. As soft foot typically results in static eccentricity, this combination of faults is very common.

Both motors were located relatively close to each other, and both of them were driving centrifugal pumps of the same type through direct coupling. Both motors where operating at the same load level. Motor case 1 is considered healthy while motor case 2 is considered to have a combination of static eccentricity and soft foot. As soft foot typically results in static eccentricity, this combination of faults is very common.