Born from an intuition of the Italian physicist Cristiano Galbiati and devised for fast and simple manufacturing, MVM innovative device for assisted breathing has been developed in just over a month through a broad international scientific collaboration, with the support of some Italian companies like the leader Elemaster. An excellence free-access project, which in just 6 weeks has obtained the emergency certification by the United States certifying body FDA, Food and Drug Administration

In these last months, mechanical ventilation has become very topical again, unfortunately owing to the effects of Covid-19 virus diffusion, turning assisted breathing devices into indispensable necessary equipment. A context in which the difficult provisioning, dictated by a demand exceeding the availability of devices, has caused not few problems, putting the healthcare system to hard test on a national and international scale.

MVM, acronym of “Milano Ventilatore Meccanico”, is an international project conceived in Italy precisely as solution also to these criticalities, and developed in just over a month due to the collaboration of a large group of scientists, clinicians and healthcare professionals, as well as thanks to the support of some Lombard companies that have allowed its feasibility in a very short time. An all-Italian manufacturing chain of which Elemaster has been leader company and coordinator since the early phases, enabling the implementation (in record time) of the first prototypes. Precisely at Elemaster headquarters at Lomagna (LC) we met Cristiano Galbiati, creator of the project, professor of Physics at Gssi (Gran Sasso Science Institute) and at Princeton University in New Jersey, member of Infn (National Institute of Nuclear Physics), for fifty years engaged in the international collaboration “The Global Argon Dark Matter Collaboration (GADMC)”, with research activity on dark matter, an invisible component of universe, with experiments at Infn National Laboratories of Gran Sasso and at Canadian Snolab and Triumf laboratories.

«The implementation of sophisticated experimental instruments for the research in fundamental Physics –Galbiati states – has allowed the development of specific competences in the ambit of gas management systems and of complex control systems, similar to those used in lung ventilators equipping hospitals, and also other precision medicine branches. The challenge consisted in succeeding in designing, manufacturing and certifying a safe efficient ventilator, equipped with an advanced control system permitting different ventilation modalities, yet at the same time characterized by simple design. A design based on components easily provisioned on the market, to be quickly produced in various Countries».

From the project to the prototype

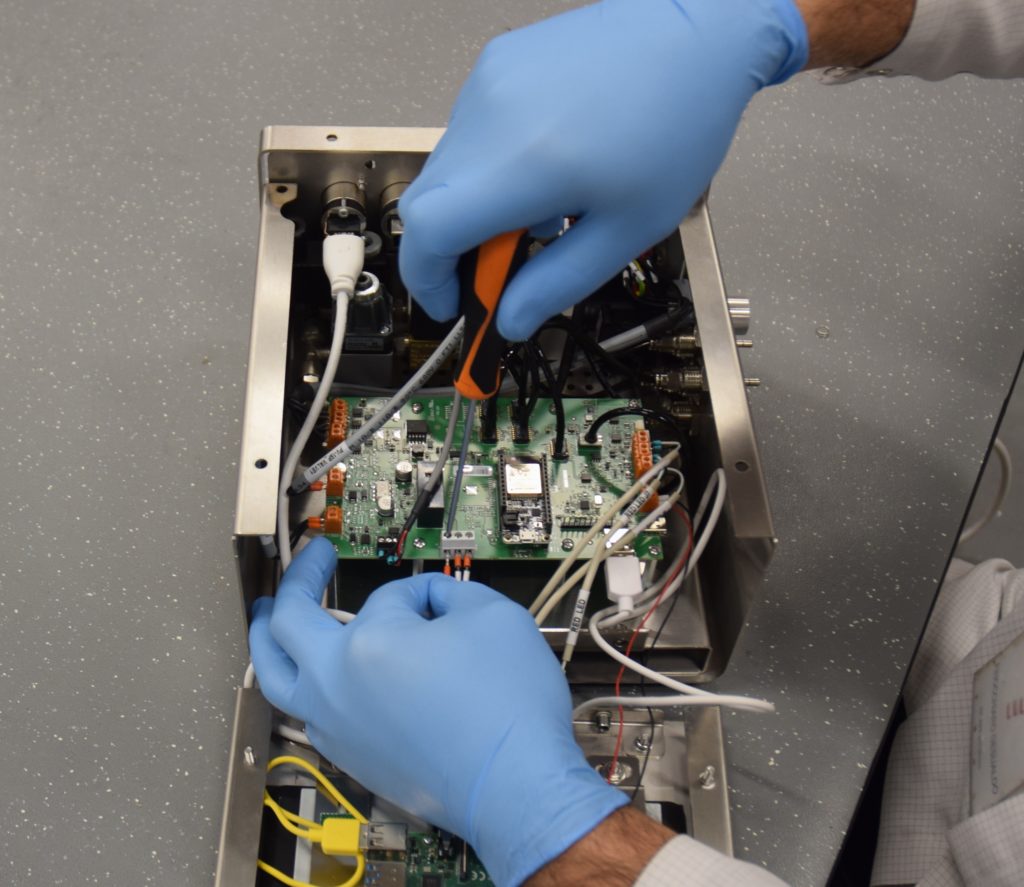

Temporarily set aside their studies on dark matter, scientists have made available know-how and experience to start the development of a first ventilator prototype by ventilator repair and support centre of Sapio Life company at Vaprio d’Adda (MI).

The synergy and the direct constant collaboration with the Department of Physics of the State University of Milan contributed in speeding up all project stages, as well as the support by Elemaster and by other Italian companies involved, such as Nuclear Instruments, AZ Pneumatica, Saturn Magnetic, Bel Power Europe and Camozzi.

MVM ventilator draws inspiration from the ventilator developed by Roger Manley in 1961, based on the principle of the “possibility of using the pressure of the gases from the anaesthetic machine as the motive power for a simple apparatus to ventilate the lungs of the patients in the operating theatre”.

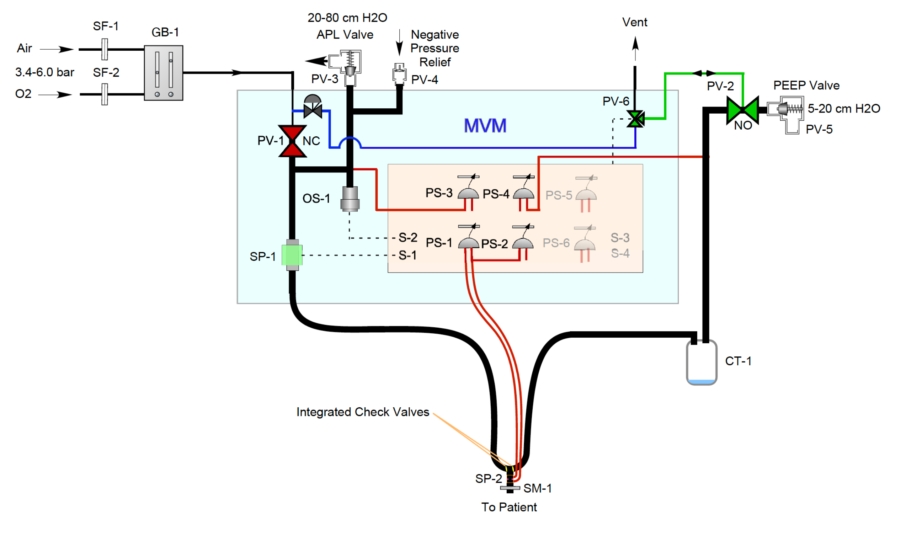

MVM can be operated in both independent ventilation (pressure-controlled ventilation, PCV) and patient-assisted control modes (pressure-supported ventilation, PSV). Directly connected to a line of pressurized medical oxygen or medical air, MVM relies on the flow regulation to deliver medical air, medical oxygenor a mixture of both to the patient, at a pressure in the suitable range for treatment. The pressure regulation of the end-expiratory cycle is achieved through a valve that sets the desired minimum positive end-expiratory pressure (Peep). Another adjustable pressure limiting valve, connected to the inspiratory line, ensures that the maximum pressure delivered does not exceed the pre-set value.

In terms of functions, the difference is also made by the electronic control unit and the whole management software, it too fruit of a circular collaboration that operated in open innovation free-access environment, to allow the fast progress of design and testing, shortening the times needed by production.

The cooperation among particle physics laboratories in Italy, Canada and United States has allowed defining common international standards for the device, maximising the benefits that derive from the sharing of information. Therefore, neither a patent nor the release of exclusive licenses are foreseen. «After accurate tests –Galbiati adds – and qualification processes of the first prototype performance with breathing simulators, carried out with the Medicine Department of Milano-Bicocca University at San Gerardo Hospital in Monza (MB), it was possible to implement in few weeks the first industrialized ventilator that has proven the correctness and the viability of the conceptual design». A design developed upon precise indications provided by who, like prof. Antonio Pesenti, specialist in resuscitation and coordinator of the Crisis Unit of Lombardy Region for Intensive Cares, daily operates on the field.

From production to the new challenge for the second generation

In MVM project, which benefitted from the support and the contribution by CNR and other Lombard Universities (Milan, Bergamo, Brescia, Pavia and Insubria), also the researchers of the Department of Chemistry and Industrial Chemistry of Pisa University and CNR IFC, supported by the staff of Tuscan Gabriele Monasterio Foundation and Sra Instruments, collaborated to exclude the release of noxious substances during the operation and to obtain the approval by certifying bodies.

Concerning assessment and certification procedures, competent institutions in Italy and abroad were involved (FDA, Food and Drug Administration and Health Canada).

The primary responsibility of the project submission to FDA for its certification was taken by Elemaster, through its International Design Center.

«In early May –Galbiati specifies –MVM ventilator, in just 6 weeks, obtained the emergency certification, i.e. Eua, Emergency Use Authorization, by FDA, Food and Drug Administration the United States certifying body. This means that since then it has been authorized to join the hospital equipment of the Countries that acknowledge the American certification».

An important step. Undoubtedly, a great satisfaction for the efforts lavished until now by all protagonists at stake, but certainly not a finishing line, as Galbiati in person confirms: «The project – he ends – is not accomplished at all. If on one hand the production in Italy is a concrete fact, due to the joint coordination with Elemaster, the large-scale one in other parts of the world is constantly evolving. We have defined some provisioning chains and identified some qualified companies that have shown interest in supporting this project of global scope. Companies that, like Elemaster, must be also certified to meet the very high standards required. As interesting is the development in course of MVM+, a second generation of MVM, more integrated, implemented by pursuing the same philosophy focused on user-friendliness and low-cost feasibility, but provided with even more advanced functions».

Founded in 1978, Elemaster stands out in the international scenario as Mechatronics Service Provider, offering services of design and manufacture of high-tech electronic equipment. Thanks to its distinctive know-how gained on processes, today it supports its customers overseeing the entire lifecycle of an electronic product:• Original Design Manufacturing: R&D services, industrialization and certification of electronic devices. • PCB Manufacturing: inhouse production of printed circuit boards. • Cable Manufacturing: in-house production of cables. • Electronic Manufacturing Services: rapid prototyping and serial assembling of electronic boards. • Mechatronic Services: mechanical integration services and testing of subunits and finished products. • Logistic and After Sales: logistic services and after sales assistance.

Operating in Italy, United States, China, India and Tunisia, Elemaster Group stands out on the market as One Stop Shop for its customers who are the major global players in high-tech sectors, such as railway, medical, avionics, automotive, industrial automation and energy. The services offered concern the entire product lifecycle, from the production of printed circuit boards to design, certification, industrialization, prototyping and production of electronic boards and products, to logistics and after sale services.