What factors determine the success of a company and allow remaining on the international stage, keeping pace with times and technologies? Every entrepreneur ponders this question when he must implement a successful strategy for his business, analysing all the elements that share in the achievement of wished results.

We have discussed this key issue with the Managing Director Massimiliano Signoretta and Fausto Rinaudo, Sales & Marketing Director of CM, who have highlighted the company’s history and present reality.

The human capital

Massimiliano Signoretta, Managing Director of CM, relies on a technical background that plays a fundamental role in the business management, as well as on specific competences that allow him to focus the company’s entrepreneurial vision on technology. «We started as manufacturers of machines for the production of electric motors in years when the technological forefront was represented by automation; several customers used manual or semi-automated machines suiting productions that currently would seem minimal. A market with growing attention to performances, the reduction of manufacturing costs and increasingly high qualitative standards has made our sector more and more demanding and has urged players to keep pace with technology and automation, without however neglecting the economic aspect because the competition still concerns prices, despite all. Certainly, it was strategic to build an in-house division intended for the production of our machines’ equipment – the core of the system – thing that permits us to manage directly the design, the production and commissioning, assuring customers the utmost quality and shorter times between the testing and production start. However, I would like to acknowledge that the credit of CM’s growth goes not only to the technological and performance level but it must also be acknowledged to an internal staff composed by highly specializes resources, able to work in team and aimed at a successful goal that belongs to the whole company but, first of all, to the workers who are daily committed so that management strategies are not only theory but are mirrored in results».

Fausto Rinaudo, Sales Director of CM, has operated for several years in the electric motor sector and is specialized in international marketing, with specific expertise in China and United States, where over the years he has gained direct experience. «When I started my collaboration in CM, our market of electric motors was specifically dedicated to the household appliance industry. In the last four years, we have focused our attention on the automotive sector, especially on the electric/hybrid car, with automotive engines. The e-mobility sector has then proved to be the trump card on which to stake at present and in the future, considering to what extent the boost towards the environmental sustainability has become the main priority for many Countries. It was not easy to approach such an innovative and unexplored ambit and to develop business through a strategy taking many factors into account, like the technological content, the economic factor, delivery times and technical specifications. We are very proud of our positive trend, the market has positively welcomed our proposal and our commercial network has been implemented along the years with dynamic efficient collaborators who locally operate abroad, where we are currently present, in particular in China and United States. In Europe, we had been already operational for several years and we count among our customers some historical industrial Groups that in the sector of electric motors are considered market protagonists in international ambit. Obviously, the challenge is not won, we are boosted by the market itself to provide proactive answers, possibly anticipating sector trends to be proactive immediately ».

In the last four years, we have focused our attention on the automotive sector, especially on the electric/hybrid car, with automotive engines. It was not easy to approach such an innovative and unexplored ambit and to develop business through a strategy taking many factors into account, like the technological content, the economic factor, delivery times and technical specifications. We are very proud of our positive trend, the market has positively welcomed our proposal. Obviously, the challenge is not won, we are boosted by the market itself to provide proactive answers, possibly anticipating sector trends to be proactive immediately.

From engineering to production start

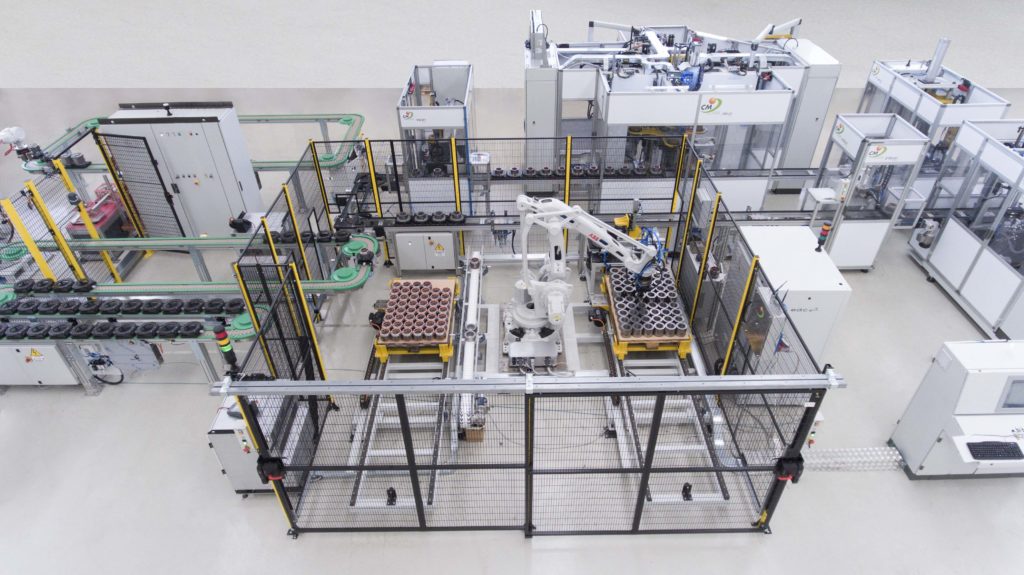

In its first years of life, CM has integrated outstanding specialized resources of the former PAVESI, top player in the manufacturing of machinery for electric motors. Afterwards, CM’s production has evolved, implementing automated systems and lines with a high level of integration and automation, thus suiting a more and more challenging market in terms of technology and performances.

«The activity ranges from the production of stand-alone machines to machining centres and fully automated lines, from the retooling of already existing machines to the supply of specific equipment and spare parts. Hand in hand with the rise of the manufacturing capacity, CM completes its staff with highly specialized resources, able to take care of customers suitably in each design phase, from the engineering to the commissioning».

The company has succeeded in developing systems to supply the ideal solution for each operation, like Slot Insulation, Winding & Insertion, Phase Barrier Insertion, Pre- Forming, Lacing&Knotting, Final Forming, Leads Connection and Testing. All referred to a complete range of motors like EV-HEV, compressor, pumps, brushless, servo, stepper, in the IEC 56÷ 355 range.

«The experience gained on the field goes on hand in hand with the constant unceasing commitment to training: the autonomous design and production of all equipment, which are the technology’s core, the process control, from the motor analysis to the equipment production, assure the finished product quality».

Flexible automation

The automation level of the machines produced by CM is determined according to customers’ requirements: the range of catalogue machines goes from manual stand-alone models to extreme automation, accomplished with an operating line managed by a single operator.

«Manufacturing processes conform to the most severe international regulations about the quality control and the main commitment consists in searching for the best solutions, aimed at improving quality and productivity, with customer satisfaction as goal, the focus of all of our activities and undisputed protagonist of the corporate mission».

An international sales network

The production increment, together with a constantly changing organization, have allowed CM to develop an international sales network operating on various strategic markets. «We can work directly on the spot, in both the commercial and in the operational design stage, sending our team directly to customers’ factories or through our remote support, for the standard daily activity of assistance in production».

Development drivers

The innovation upswing has been an irremissible condition for CM and its growth. Besides, all development assets have been actually dedicated to the automotive industry, with specific focus on motors for hybrid and full electric vehicles, making the company become a reference reality for all primary automotive Groups in Europe, Asia and North America.

The use of high capacity/speed communication protocols in the data transmission has allowed further enhancing the services of integrated diagnostics and remote assistance, in line with the requisites of Industry 4.0, with the target of providing customers worldwide with a constant process monitoring.

A market with growing attention to performances, the reduction of manufacturing costs and increasingly high qualitative standards has made our sector more and more demanding and has urged players to keep pace with technology and automation, without however neglecting the economic aspect because the competition still concerns prices, despite all. The credit of CM’s growth goes not only to the technological and performance level but also to an internal staff composed by highly specializes resources, able to work in team, and to the workers who are daily committed so that management strategies are not only theory but are mirrored in results.

All necessary resources for the design, development, production, installation and production start by customers’ plants are in-house and make up a highly specialized multicultural work team, able to interact with Italian and foreign interlocutors and to solve whatever problems in very short times.

Besides satisfying the various demands, the company’s commitment to production aims at exceeding market expectations, optimizing the various manufacturing phases at best due to the experience gained along the years. «Our specialized engineers are entrusted with the customer care under all respects and, in particular, in the machine setup. The manufacturing management is focused on delivery terms that, consistently with the machine complexity, must be strongly reduced to meet customers’ productivity requirements: the time factor is a crucial element for them in the plant choice».

The corporate propensity for accepting the new challenges issued by the market, maintaining a high qualitative level and a constant research and implementation of productive processes aimed at the time and cost optimization. «It is a mix of elements that makes CM agile, reactive and ready to anticipate sector trends».

All equipment of CM machines are in-house designed and manufactured in a dedicated division, to offer absolute quality, with the possibility of being very efficient for the optimization/debug.