In the EV revolution, one of the most fascinating challenges is to ensure proper thermal management and electrical insulation of motors, batteries and other key components.

Politubes has engineered a revolutionary solution (EVtubes) improve stator slot thermal management and insulation of electric motors (EV & HEV), which use copper hairpins & I-Pins windings.

Copper hairpins guarantee better performance in terms of efficiency, power density, cost, acoustic impact and are in line with the latest technological developments in the E-Mobility industry, particularly with reference to EV traction motors.

For the insulation of stator slots with hairpin windings, Politubes suggests the use of custom-designed NKN (Nomex /Kapton /Nomex)* – NMN (Nomex /Mylar /Nomex)* insulating spiral tubing.

For the insulation of stator slots with hairpin windings, Politubes suggests the use of custom-designed NKN (Nomex /Kapton /Nomex)* – NMN (Nomex /Mylar /Nomex)* insulating spiral tubing.

Multi-layer Nomex/Kapton/Nomex (NKN) spiral wound tubes are thinner than traditional insulators tapes and are supplied with thicknesses of only 0.13 and 0.19 mm without overlap.

The reduction in thickness and the absence of insulating film overlap within the slot guarantees some dramatic improvements in the following macro-areas:

- Thermal Management

- Insulation & Reduction of Partial Discharges

- Filling factor, Performance and Motor Life

- Handling, Mechanical Properties and Waste Reduction

Thermal Management

– The thermal conductivity within the stator slot improved dramatically due to the reduced thickness of the spiral wound tubes, which are produced without overlaps. Actually, the overlapped area of traditional tapes is one of the areas where the highest temperatures can be achieved;

– Overheating can reduce motor efficiency, deteriorate key components and reduce the resistance of electrical insulation. However, improved heat dissipation can translate into a positive impact on all vital matrix and motor lifetime;

– Reduction of dangerous heat peaks that can damage the magnetic flux of the rotors’ permanent magnets over time;

– UL system integration up to 220°C.

Insulation & Reduction of Partial Discharges

– Reduction of partial discharges (PD) thanks to hermetic tube closure;

– The hermetic tube closure provides a much higher level of electrical insulation than conventional films, where the overlapped area remains the weakest part in the insulation chain;

– Reduced risk of insulation displacement caused by micro-vibrations during motor lifetime and that can cause partial discharges (PD);

– Improved uniformity, thermal, dielectric and chemical insulation;

– Dielectric strength up to 12 kV;

– Excellent impregnation properties with traditional resins.

Filling factor, Performance and Motor Life

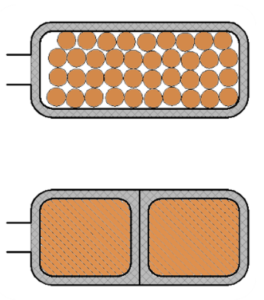

– The reduction in the size of the insulator due to the lower thickness and absence of overlaps makes it possible to increase the amount of copper inside the slot with consequent optimization of torque and improved motor performance;

– The reduction in the size of the insulator due to the lower thickness and absence of overlaps makes it possible to increase the amount of copper inside the slot with consequent optimization of torque and improved motor performance;

to improve the filling factor of copper inside the slot with consequent optimization of torque and improved motor performance;

– The reduction of heat peaks and partial discharges guarantee longer motor life.

Handling, Mechanical Properties and Waste Reduction

– The absence of overlaps reduces the risk of jamming when inserting hairpins into the slots, reducing scrap and increasing productivity;

– Reduction accidental cases where the insulation tape is pushed out of the slot during hairpin insertion;

– Reduction of the risk of displacement of the insulation when curving the hairpin;

– The usage of Nomex 410 instead than 464, reduce the

Nomex dust on stator during hairpin insertion;

– Superior mechanical tensile strength.

Nomex /Kapton /Nomex tubes are custom-designed for both 400V and 800V motors.

For 800V motors we recommend the use of special grades Nomex (818 – 864) and Kapton MT+ with state-of-the-art dielectric, heat dissipation, flame resistance and durability performances.

NKN insulating spiral wound tubes can be formed inside the slot or can be easily inserted onto copper bars taking the rectangular shape of hairpins.

World-leading companies in process automation already offer fully automatic systems for inserting NKN tubes into stator slots.

For automotive applications, Politubes also supplies ultrasonically welded caps made from a combination of Nomex 411 and heat-shrinkable polyester used for insulating joints, motor cable terminations, and other components ensuring uniform insulation throughout the system.

The European one stop solution for windings

Politubes is an Italian company specialized in engineering spiral wound tubes and insulator caps for the electromechanical and automotive sectors.

Politubes is an Italian company specialized in engineering spiral wound tubes and insulator caps for the electromechanical and automotive sectors.

This is a hyper-validated technology as demonstrated by almost 50 years of activity and several patents obtained through continuous innovation.

UL TEOU 2 – 8 nr E350605 and ISO 9001:2015 certifications are a guarantee of the company’s philosophy. Politubes, also started the process of getting IATF 16949 certification.

For over 50 years, FAET has been one of the main European companies in the electromechanical components and spare parts market. FAET can supply everything required for the construction of windings for electric motors, generators, transformers… in all insulation classes.

For over 50 years, FAET has been one of the main European companies in the electromechanical components and spare parts market. FAET can supply everything required for the construction of windings for electric motors, generators, transformers… in all insulation classes.

The goal, together with Politubes, is to be the European one stop solution for all insulation components with products dedicated to electric vehicle sector.

*(Nomex and Kapton are DuPont registered trademarks)