Pioneer in the sector of electric connections, in the late Eighties TE Connectivity invented solutions to replace the old solder process technology for magnet wire connections. The company, multinational worth 14 billion dollars, supplies all-round solutions not only for the electric connection part but also for plastic insulation and assembling.

MAG-MATE connector with Multispring pin is a combination of two key technologies that eliminate the customer’s need to solder. It provides the ability to directly connect magnet wire to a Printed Circuit Board with no solder. Traditionally, the process is to solder magnet wire to a pin, assemble the PCB to the pin, and then solder the PCB to the pin. But now no more, thanks to this product that allows solderless magnet wire termination in the IDC (Insulation Displacement Connection) at the bottom and solderless PCB termination through press-fit Multispring pin on the top.

IDC technology

In the last 15 years, TE Connectivity has developed an optimal solution for the magnet wire termination. It is the family of TE MAG-MATE products for the magnet wire termination, used by many outstanding companies on a world scale in the production of motors and pumps. This product is based on the technology of Insulation Displacement Connection (IDC). For over 40 years, this IDC technology has proven to be an efficacious alternative to the wire stripping and soldering in thousands of applications.

«They are products –Ugo Aime specified – belonging to the “Appliances” business unit, but they can find all-round uses, for instance in the automotive, industrial and medical world, and in all various market applications where a magnet wire termination is demanded».

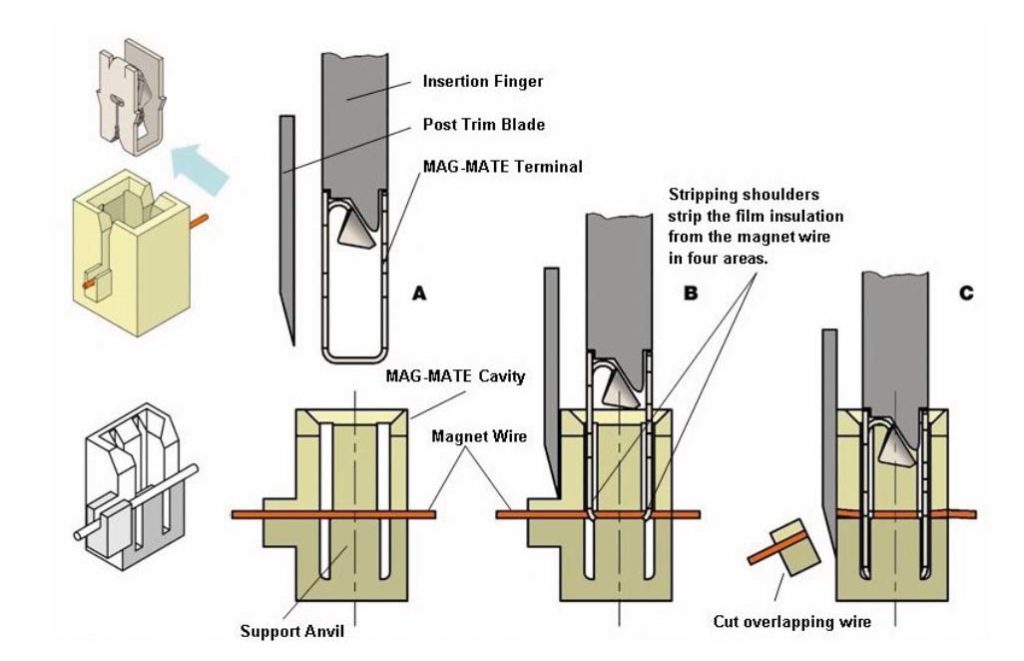

In IDC system, terminals are provided on a metal band. Manufacturers insert terminals into a plastic cavity by using automatic or semi-automatic insertion equipment. The plastic cavity must use glass-filled material to have mechanical stability and can be molded in the customer’s coil or can be part of a separate component. This molded cavity has two slots on the opposite sides and an inlet chamfer on each slot. The magnet wire coming from the coil is pre-positioned in these two slots manually or through a winding tool. The wire rests on a support or on an “anvil” in the cavity.

The MAG-MATE terminal has two IDC slots with inlet chambers on the input points of slots. The terminal is positioned on the magnet wire in the plastic cavity and then inserted. Terminals “clean” the insulating film from the wire surface during the insertion. When the terminal has been definitively positioned, the wire is fixed between the two slots for the insulation displacement, to assure a safe and reliable termination. During this process, hermetically sealed contact points are created between the wire and the terminal. The opposite side walls of each slot of the terminal have a residual elastic energy that keeps the pressure constant on the wire, assuring a safe and reliable connection in the long term. Molded plastic slots fix the wire on each side of the metal terminal, assuring an anti-traction action.

The MAG-MATE terminal has two IDC slots with inlet chambers on the input points of slots. The terminal is positioned on the magnet wire in the plastic cavity and then inserted. Terminals “clean” the insulating film from the wire surface during the insertion. When the terminal has been definitively positioned, the wire is fixed between the two slots for the insulation displacement, to assure a safe and reliable termination. During this process, hermetically sealed contact points are created between the wire and the terminal. The opposite side walls of each slot of the terminal have a residual elastic energy that keeps the pressure constant on the wire, assuring a safe and reliable connection in the long term. Molded plastic slots fix the wire on each side of the metal terminal, assuring an anti-traction action.

Aluminum termination

The termination of the aluminum magnet wire use to represent a challenge for the IDC technology. Environmental and mechanical stresses cause in aluminum many more “creep” and “stress relaxation” phenomena than what with copper. Magnet wire manufacturers have succeeded in minimizing “creep” and “stress” phenomena.

The studies carried out by TE indicate that motor manufacturers can shift from copper wires to aluminum wires and use standard insulation displacement terminals to eliminate the pre-stripping and soldering that need specialized manpower.

To assure that the connection process leaves the wire in an optimal region of the connector slot, technicians must indicate the optimal insertion depth for the single application.

Compact recently patented connection

«Currently, – explained us Ugo Aime, Product Manager Appliance of TE Connectivity – the market trend is focused on developing products that can be used in applications where space is a premium and design-to-cost is extremely important. Reducing components and material, keeping performance, is paramount for success.

According to this strategy, we have developed a new proprietary concept with the support of of P.K. Senthil Kumar, Global Engineering Manager who works in our Bangalore branch, in India.

This concept relates to an assembly for electrical devices that demand a compact and automated solution to transfer power from a power source.

The assembly comprises a TE terminal with IDC that allows solderless magnet wire termination at the bottom and solderless PCB termination through press-fit on the top, with a tab connected with PCB using again press-fit termination».

- Large gas-tight contact zone

- High reliability due to stored energy

- Minimum damage to plated-through holes during application

- Especially suited for multi-layer PCBs

- More economic board manufacturing due to larger hole tolerances compared to the use of a solid pin Application can be made by the end-user

- High-end TE Connectivity application tooling available

- Extraction force equal to Pin/PCB min 40N

MAG-MATE Connector

- Terminates all magnet wire film insulations

- Eliminates need for pre-stripping conductors

- Eliminates need to solder/weld

- Excess magnet wire is automatically trimmed during the termination process

- Simultaneously terminates two magnet wires of the same size in one terminal (for splicing or bi-filing) Available in strip form for semi-automatic or fully automatic insertions

- High speed, fully-automated integrated systems provide uniform terminations reliability at the lowest possible applied cost

- Clean metal-to-metal interface produces stable, gas-tight electrical terminations free of oxides and other contaminants

This solution offers different advantages:

- Cost efficiency: when used with compliant pin variants, a compact solution is obtained that can be automated;

- BOM (Bill of Material) reduction: the connection can be completed with two parts only;

- Reliability: this solution needs minimal intervention and precisely controlled termination eliminates human error;

- Cleanness: it is environment friendly since eliminates need for pre-stripping and pre-solder/weld.

Moreover, «Customers can design their products without using wires and cables; we want to protect this solution of ours on a global scale» – specifies Aime.