After outlining the product and support proposal for the electric motor world in automotive and/or appliance ambit, we have asked interviewed companies their point of view on possible future scenarios/technological trends.

“The most felt requirements in the sheet metal forming market, especially for the automotive sector– highlights Michele Archenti, Sales and Marketing Manager AIDA Europe – are, and will increasingly be, more control and more automation of manufacturing processes. The revolution called Industry 4.0, aimed at boosting innovation in industrial field, mainly focuses on the theme of the integration and the connection of industrial machines to the corporate net. Concerning this, the most important novelty at which we are working, concerns the use of Machine Learning algorithms to offer advanced preventive maintenance solutions able to help us in preserving the most important good of each customer: manufacturing continuity”.

Precisely according to this vision, AIDA group has already developed and implemented its complete solution for the data processing (through cloud computing): AiCARE (AIDA Information Care System). It can provide advanced information about the production and maintenance state of each single press, such as, just to make an example, manufacturing data, data on energy consumptions, on the oil quality or the operational temperature, or data regarding the use degree of each single element that composes the press.

“The AiCARE system– adds Archenti – has been conceived to be integrated on all of our press typologies but, at the same time, it can be seen as an external device to be implemented on already installed presses”.

Therefore, it is a solution “that can be retrofitted” on the machine fleet already installed. Not only AIDA presses are concerned but the installation is possible also on other manufacturers’ presses.

Concerning possible future trends and scenarios, Bluergo thinks that the electric motor evolution as traction, in automotive ambit, will have its course, with times a bit delayed compared to what imaginable just some years ago. Owing to different reasons, as Andrea Cusinato, Sales Department Bluergo, specified: “Without prejudice to the environmental and performance benefits, there are some criticalities and difficulties not completely solved, I think. I am referring, for instance, to an infrastructure and to a grid energy not ready to transpose “big numbers”. Likewise, the vehicle cost for end-users, even if constantly adapted, unfortunately does not seem affordable for today’s users of small subcompacts, yet. In other words, times are not mature for a mass diffusion, yet. From our point of view, we believe instead the petrol/methane, diesel/methane conversion technology is more within reach”.

In the last biennium, the company has been very active and committed to the latter context, with the supply of tailored electromagnetic components.

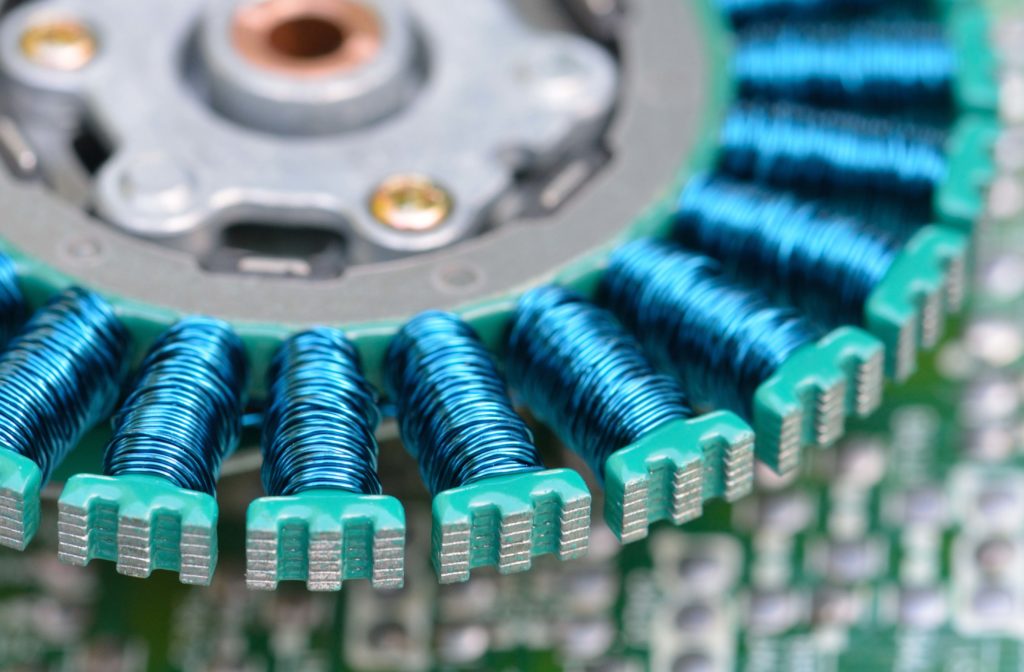

“If, instead, with electric motor – specifies Cusinato – we mean not only the traction, it is indisputable it is in constant evolution. Especially if we refer to brushless motors, which nowadays represent the almost totality of motions and drives equipping a car”.

Bluergo has been committed to this ambit for years and it is investing huge resources in it. A strongly growing market that, today, absorbs a significant percentage of the corporate production.

“Referring to the Home Appliance sector – adds Cusinato – it is following the same evolutionary course, with the replacement of standard single-phase motors with brushless technology. However, also in this case the cost aspect hinders its mass diffusion”.

—

Cagnoni confirms the electric motor world is living a constant growth in the automotive and appliance sectors.

“Nevertheless – specifies the managing director Giordano Sorci – the brushless motor is rapidly spreading, widening applicative opportunities. Today, also for this reason, our customers, I would say about 10% of them, are diversifying productions by introducing the brushless technology, too. However, not all sectors can avail themselves of these typologies, therefore I believe the conventional brushed motor still has several decades of career in front”.

—

Automation is increasingly shifting towards motors produced in smaller yearly quantities. This is the point of view of Dema that, by voice of the owner Mr Cesare Librici, confirms how such datum influences the technological requisites demanded for its plants.

“If previously – states the engineer Librici – typically one of our automated machines was required by one of our customers that had productions of 500,000, one million of parts yearly, today we have dropped by one order of magnitude. This means the demand for the part of our competence is oriented towards a fully automatic process. And no longer semi-automatic or even manual. This interpretation concerns both the automotive and the industrial world. More complex is instead interpreting trends and scenarios for the appliance industry that, still according to our point of view, does not seem to show particular interest in investments in new products today”.

Clear and precise also the vision of Demak about possible future scenarios/technological trends where the electric motor will be the protagonist.

“Certainly electrification – states the Technical Sales Manager, Massimiliano Balboni – already in course for some years, will become a “vital” and decisive step for all OEMs and for the whole chain. Especially, however, for companies that will mandatorily need to integrate into their manufacturing cycle technologies with zero or minimal impact on the environment. Therefore, it is undoubted that companies themselves, besides investing in R&D activities for the development of electric traction with more autonomy, will be also requested to provide for investing in “Eco-Friendly” technologies, which can grant, at the same time, excellent-level performances of the electric motor and of other components”.

—

The future of automotive is electric. Sergio Iori, president of EuroGroup, has no doubt.

“The automotive industry– he affirms – is getting ready for the increment of the demand for electric vehicles. We cannot establish with certain responses, yet, whether and when the car with thermal motor will end, whether and how much the hybrid traction will still develop. However, it is certain the activity that today concerns the productive developments of electric vehicles is, according to many, a real Tsunami and, anyway, an epochal turning point”.

—

Christian Grob, Supervisory Board Chairman of GROB-WERKE, underlines how it is important to remind the e-mobility is still a relatively new concept for the automotive field.

“All market players– he declares – must adapt their approach. Working in strict collaboration with primary sector brands, it was immediately clear that there was a big need of mass production installations in the automotive industry, with particular attention to key components, that is to say the electric motor and battery components. Currently, designs are created and developed only through a strict consulting with the automotive industry. Even if markets are reacting to this with different speeds, Grob sales have already suited new technologies worldwide”.

—

Wide, efficacious and detailed is the reflection expressed by Inarca on possible future scenarios/technological trends, implemented in automotive and appliance ambit.

“In automotive ambit – highlights the sale manager Alessandro Rocchi – the increasingly extended demand for components managed by electronics makes the need of connecting mechanical parts to boards or circuits more and more frequent. This will lead to an ever-rising diffusion of the mechanical cold junction, much more efficient than welding, due to both the minor problems in junction phase and the possibility of replacing parts quickly. Consequently, the market trend is favourable for us, since we have invested for years in Crimp and IDC technologies, where today we can say we are technological leaders. Moreover, the more and more diffused presence of aluminium, instead of copper, as material used for electric motors’ windings works for us, as we have developed for years more and more efficient solutions for applications of this kind”.

Referring to the appliance world, Rocchi points out that the technological evolution of the household appliance sector determines an increasingly massive presence of electronics, which exponentially increases the number of connections for each single device and produces more and more complex geometries.

“The successive step – he adds – will be the massive diffusion of iOt, internet of things, which will further boost this phenomenon».

In this context, Inarca proposes itself as technological reference partner: for years, in fact, it has developed a line of specific solutions for the mechanical cold junction (both Crimp and IDC), which allow utmost efficiency in application phase.

—

In the opinion of Enzo Montani from Piciesse, certainly last years’ data highlight a strong growth of the innovative mobility and motion: “Beyond the mobility in the strict sense – he adds– the sector dedicated to the terrestrial motion and to the introduction and refinement of more and more technological and attentive means is increasingly protagonist. We are referring to trains for electrified lines, to hybrid/electric cars, to e-bikes, to electric scooters, to segways and to hoverboards. Besides, aware of facing a more and more diffused electric production, probably the need of developing smart flexible grids, able to manage peaks and to distribute energy safely, will rise. This will highlight the importance of the so-called smart grids and will gradually require efficient and complete management and communication systems of grids themselves”.

More and more refined technology for more efficient and safer systems. This is the synthesis by Rodolfo Risatti, owner of Risatti Instruments: “We believe – he affirms – in the future, technology can nothing but refine and reach specialized levels that will grant more efficient and safer systems. According to this perspective, we daresay the technologized automated drive will be used on all transport means”.

—

The point of view of Samac reveals how the next evolution, already partly in course, will reside in the shift from electrification to electronification. A step that, for the company, will make the critical components of complex systems – like for instance the motor in a car but also an electric axis in machines – become independent in the management of their operation and maintenance parameters.

—

TE Connectivity estimates that trends and possible scenarios for the future are oriented towards an increased usage of aluminum wires.

Ugo Aime, Product Manager, explains and concludes: “Where there are no particular problems with the space for the components, more competitive solutions which are cheaper and lighter will be available”.

—

Concerning future trends and scenarios, Zoppas Industries Heating Element Technologies highlights a first big discriminant among hybrid, plug-in and full-electric vehicles. Moreover, car typologies will be subdivided by autonomy range and by market target, luxury and performances, too. The company’s hypothesis envisages a more and more fragmented market, to meet the manifold requirements that, in combination with the new trends of Megacities and of connectivity, will be defined by end-users. Concerning heating, the macro-typologies that Zoppas Industries Heating Element Technologies glimpses in the next future are the following: air heating for small cars for city-urban use; heating through fluid circuit loops for the cars of the average range; heating by heat pump for “premium” cars; heating through radiant surfaces as possible long-term evolution in the car interior.