FAET laboratory participating in UL THIRD PARTY TEST DATA PROGRAM, is able to execute the Sealed Tube Test for the UL Electrical Insulation System Modify.

The participation allows FAET to execute tests on customers’ behalf and results are accepted by UL as if UL itself had directly obtained them, certifying the conformity to the UL 1446 standard.

Thanks to this test, manufacturers can modify the adopted EIS by introducing new materials for greater diversification of their supply chain.

FAET’s mission is simplifying the daily routine of OEM, including the manufacturers of electric motors that need a certified Electrical insulation system in their inside.

The laboratory headquartered at Rozzano is unique of its kind in the SEMEA area, then the relative proximity to the structure, especially for the South area of Europe, is a logistic plus that allows avoiding travels overseas.

Highlights include the possibility of interfacing with a single partner in the process of modification and adoption of the insulation system, with specific advisor skills in design choices.

Besides, the availability of the materials to be tested or their easier provisioning are benefits that add to the others, permitting a saving of the time needed for the test execution.

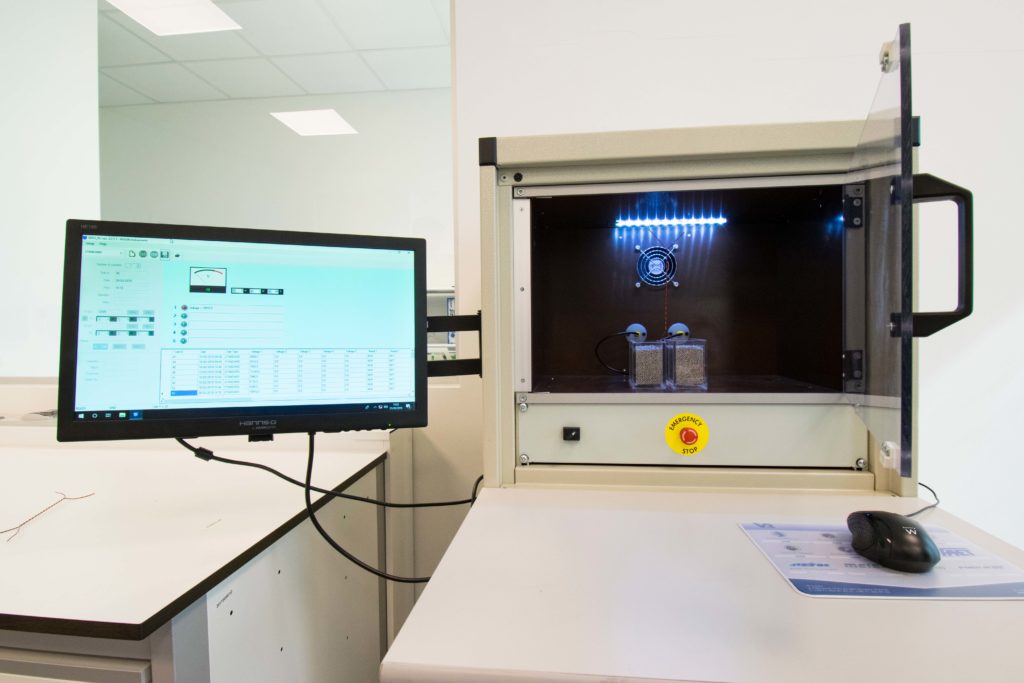

The test consists in the comparison between an original insulation system called “Reference” and one or more systems customized by the customer and called “Candidate”. The test provides for the insertion of all components into two glass tubes, one containing the components of the original system and one with the components of the new system.

The tubes are closed with specific flanges and stored in an oven for 14 days, at a temperature exceeding by 25° the one of the systems under testing.

After opening them, the electric discharge test is executed on twisted pairs, at least 10 per tube. Therefore, 10 results per tube are achieved and averaged out, the average value of the “candidate” tube is compared with the average value of the “Reference” tube.

If the average calculated for the modified system is within 50% of the original one’s value, the test is passed and then that modify EIS can be used for manufacturing the electrical insulation system under construction.

Group turnover is €27mln with more 3000 active customers and exports in 50 countries.