Piciesse Elettronica manages a broad range of technologies for a wide number of sectors, one of them concerns big copper thicknesses and is called also “Heavy Copper”; it refers to printed circuit boards with high copper thickness, exceeding the “standards” and starting from at least 105µm.

Nowadays Piciesse Elettronica, with its 25 years of experience, is a leader company in the market of Printed Circuit Boards. Over the years, it has succeeded in managing a broad range of technologies for a wide number of sectors, one of them concerns big copper thicknesses and is called “Heavy Copper”, too.

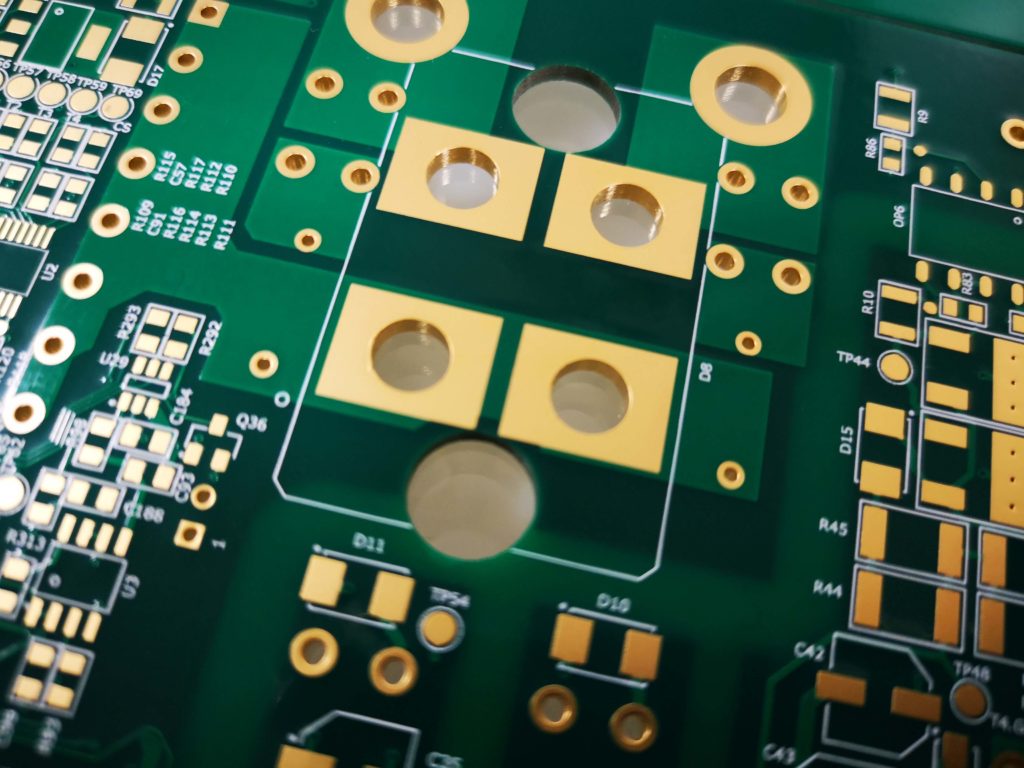

The Heavy Copper technology refers to printed circuit boards with big copper thickness, exceeding the “standards”, starting from at least 105µm. To process circuits that start from 105µm of copper as “minimum” thickness, it is necessary to conform to special requisites and, as plant, to rely on the most advanced production technology and techniques, in addition to excellent process monitoring.

The circuits based on heavy copper technology can be single-sided, double-sided or multilayer; due to its knowledge and Know-How, Piciesse can manage maximum thicknesses of 2 mm, i.e. 400µm, of copper.

Such technology proves to be particularly advantageous in the management of the thermal and mechanical stress and it benefits from the application on IMS (Insulated Metal Substrate) circuits, which allow a higher heat dissipation, thus creating a complete, performing and reliable solution.

The availability of various materials combined with different dielectric layers offers design opportunities of different nature from the thermal and electric insulation point of view.

Not fortuitously, the products that make use of such technology are “special” as they sometimes face extreme conditions. The sectors that more exploit this technology are Power, Welders, Forklifts, Caddies, Converters, Inverters, Charging, Automotive (power units), here especially in the ambit of electric vehicles, the latter in exponential growth recently.

Piciesse has specialized and has invested precisely in this sector in the last few years, making important changes:

- structural, it has bought a 5000 sq.m. shed;

- technological, introducing relevant industrial automations in compliance with Industry 4.0;

- process, it conforms to VDA 6.3 standards, through which it has been audited with excellent results and it owns a multiplicity of certifications starting from IATF, fundamental to work in this market.