The vibro-acoustic analysis is fundamental in the sizing of any mechanical component. Not only because vibrations produce both mechanical and noise effects but also because the mechanical motion can generate stress and/or undesired dynamic behaviour of the system. Besides, the induced stress is correlated to fatigue and can cause premature breakages of the device. The fatigue failure depends on the number of cycles: even if the stress level is by far inferior to the maximum tensile stress of the component, at the end a failure can occur. With the rise of the power density of electric motors and more ad more demanding specifications, the vibration forecast in the initial design phase has then become a very important matter. An operational ambit where is protagonist Spin Applicazioni Magnetiche, service company working in the sector of electromechanical device design and distribution of simulation programmes for electromagnetic devices, electric motors, mechanical analysis and control systems. «In many industrial applications – Alessandro Tassi, CEO of Spin Applicazioni Magnetiche, explains – low vibration/noise levels are demanded: from the automotive industry to household appliances, from the diversified HVAC to the variegated power tools. The comfort of end users is as fundamental as the failure prevention».

The added-value of the multi-disciplinary analysis

Forefront Finite Element calculation instruments (Fem) allow an assessment of the behaviour of an electromechanical device since the first design stages, avoiding corrective actions when it is difficult to modify already advanced design choices, unless with cost increases and with an extension of the product time to market. Spin Applicazioni Magnetiche holds the expertise to guide accurate multi-disciplinary analyses on such theme.

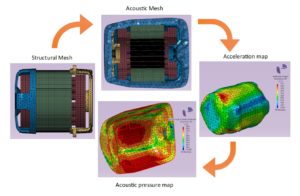

«From the electromagnetic context of the Fem calculation – Tassi underlines – we extrapolate the electromagnetic forcings and, through a dedicated connection, we evaluate, in the mechanical context of finite elements, the iterations with the mechanical structure equipped with the motor, allowing the determination of the real displacement of all parts, and eventually analysing noise radiation aspects». The company can boast multi-year experience in such applications, both through dedicated consulting in home-appliance field and in automotive sector.

As confirmed by the numerous assignments entrusted for the management of entire projects, from the initial design to the implementation of very performing prototypes, where the vibro-acoustic analysis has been the key element of the project.

High power density at the service of automotive

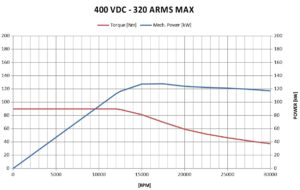

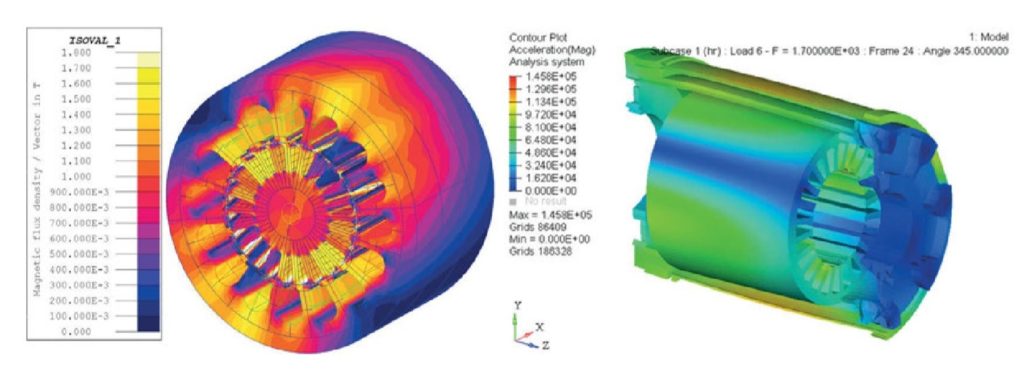

The development of a traction motor for sports cars is an example of the above- mentioned workflow. Spin Applicazioni Magnetiche, from simple inputs of power (120 kW) and speed (30,000 rpm) and maximum footprint, has guided the customer to the implementation of prototypes. «The motor design –Tassi further explains – started from the typical white sheet, with electromagnetic and mechanical optimization as elements that have guided the device development since the beginning. The electromagnetic forcings calculated have become the input for mechanical analyses; the motor structure has been optimized to reduce vibrations, stator and rotor laminations, magnets, the frame and the shields were subjected to a single vibro-acoustic optimization».

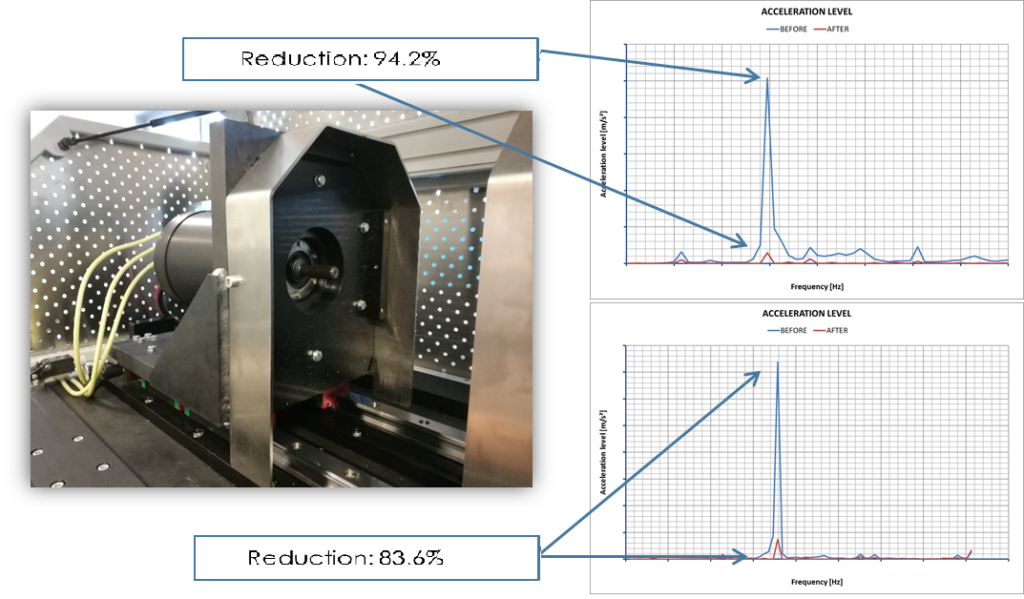

Such approach has allowed notably reducing some acceleration peaks, up to 94% versus the first hypothesized design, the thermal analysis has concluded the design course, providing this brushless motor with remarkable performances in a volume slightly under three litres. «Through this calculation method –Tassi confirms – prototypes were validated and, without turning to design modifications, we could immediately proceed to the implementation of samples for the approvals needed for the mass production. All that with notable decrease of design times and costs».

High efficiency and low noise at the service of the home appliance

The same multi-disciplinary operational methodology was applied in another successful case, for the testing of household appliance motors for which, besides efficiency, also the noise becomes a key issue that makes the difference in the product. «The electromagnetic and mechanical model of a high-speed motor for household appliances –Tassi highlights – has given excellent results of correlation with experimental measurements, too, allowing the customer to understand how to act in the reduction of accelerations in determinate harmonics that generated resonance phenomena with the entire application where the motor itself was mounted».

In many cases, vibrations can represent a wished phenomenon: for instance, in the operation of the diapason and of many musical instruments. However, more often vibrations are not welcome as they can disperse energy and create unwanted sounds and noises. For instance, in the running of cars and motors in general. The studies concerning the sound and the various vibrations are strictly connected. Sounds, pressure waves, are generated by vibrating structures (for instance vocal cords) and pressure waves can generate structure vibration. Therefore, when we try to decrease noise, the issue is reducing the vibration that causes it.

In many cases, vibrations can represent a wished phenomenon: for instance, in the operation of the diapason and of many musical instruments. However, more often vibrations are not welcome as they can disperse energy and create unwanted sounds and noises. For instance, in the running of cars and motors in general. The studies concerning the sound and the various vibrations are strictly connected. Sounds, pressure waves, are generated by vibrating structures (for instance vocal cords) and pressure waves can generate structure vibration. Therefore, when we try to decrease noise, the issue is reducing the vibration that causes it.This has permitted to act on the source of the problem, to optimize it and to avoid a long empiric approach to find scarcely flexible and expensive stopgap solutions. It is perfectly clear how the vibro-acoustic multi-disciplinary simulation approach must become a standard workflow for each designer of rotating electrical machines, so avoiding unpleasant surprises during prototype tests. «Spin Applicazioni Magnetiche –Tassi ends – can support its customers both through the supply of specific software and through targeted know-how supported by a long-term experience gained by our skilled team on such fundamental theme».

Spin Applicazioni Magnetiche is also distributor of highly professional calculation software, benchmark in the simulation field for many engineering disciplines, i.e. a very broad range of available programmes that cover all design aspects. The decennial knowhow gained in electromagnetic simulation is completed by expertise in structural mechanical analysis, multi-body, thermal analysis, fluiddynamics (Cfd), mechatronics and all that is typically included in the multiphysics design sphere. In addition,

Spin Applicazioni Magnetiche is also enabled to the training and use of calculation programmes; it supplies technical- scientific consulting, support in the development of new designs and it can take care of complete projects from the initial idea to the production of prototypes and manufacturing technologies.