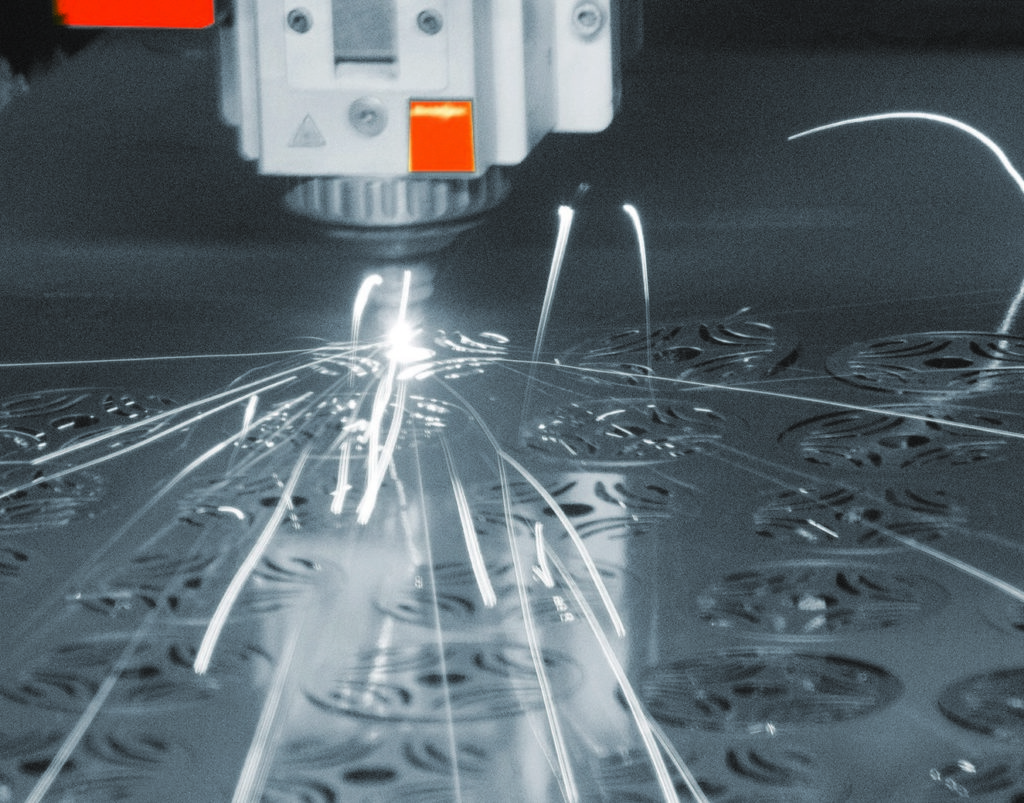

Aussafer Due is partner of excellence for the development and manufacturing of laser cut

laminations and of stator/rotor core stacks, by means of 10 fiber laser machines (the biggest subcontracting division in Italy), providing a highly customized service upon customers’ precise needs, besides offering a range of additional services.

Technology, innovation, precision and a highly specialized technical team represent the highlights that have always characterized Aussafer Due. A strategic asset that has allowed the company to become a national and international reference reality in the metalworking sector, with specific focus on the electric motor enabled by a business unit fully dedicated to the realization of prototypes, preseries, and special rotor and stator cores, through laser cutting of electrical steel laminations. The cores are realized by standard welding processes, or BACKLACK bonding.

The advantages of BACKLACK technology is better precision, stiffness and vibration performance, and the possibility of very complex shapes. Aussafer Due can deliver to its customer both loose laminations and rotor/stator cores.

A customized service that permits to collaborate with customers in the product development phase, directly dialoguing with technical and R&D offices, Universities, Research and Development Centres, for the implementation of the realistic prototype.

Aussafer Due also supports its customers in repairing and refurbishment of big rotating electrical machines, like alternators, hydro and wind generators.

For these activities, its customers can rely on Aussafer Reverse Engineering Service, that enables the acquirement of the drawing from a physical part.

Laser Technology advantages compared to traditional methods

• no stamping tool required

• cost effectiveness and short lead times for geometry

and product changes

• short time to market for realizing a functional

prototype

Aussafer Due added value and competitive edge

Strongly oriented to innovation, Aussafer Due avails itself of state-of-the-art process technologies, in compliance with Industry 4.0, with 10 fiber laser cutting machines (i.e. the biggest subcontracting laser cutting department in Italy), customized on its own specifications. As outstanding is the broad range of warehoused materials available in stock: silicon steels in thicknesses from 0.1 to 1 mm, with magnetic properties and grades from M230 to M800, also NO (NO10, NO20 etc.), on different insulations (C3, C5, C6), BACKLACK, cold rolled and hot rolled pole sheets (TF and TG), too.

Outstanding level quality for the most demanding sectors

ISO 9001:2015-certified and with its own quality system, Aussafer Due guarantees final quality and accuracy with in-process tests and checks carried out by its entrusted in-house laboratory, equipped with 3 innovative coordinate measuring machines (CMM).

The in-depth experience and the competences gained allow the company to manufacture several motor typologies: asynchronous motors (IM), internal permanent magnet synchronous motors (IPMSM) also with rotor cage, surface mounted permanent

magnet synchronous motors (SM-PMSM), synchronous reluctance motors (SynRM), linear motors, alternators and generators, also segmented. Executions manufactured for numerous customers spread worldwide, operating in various sectors, for applications in automotive and racing ambit (hydro and wind generators), traction motors, CNC machine

tools, CNC spindles, renewable energies, automation, naval and aerospace industry, oil & gas.